Environment-friendly floor

A floor and environmental protection technology, applied in the direction of floors, building elements, layered products, etc., can solve the problems of low structural strength, inability to absorb formaldehyde, poor material stability, etc., and achieve long wear-resistant service life, Wide range of use, firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

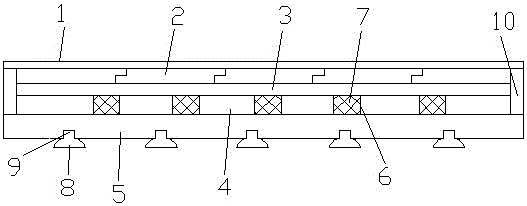

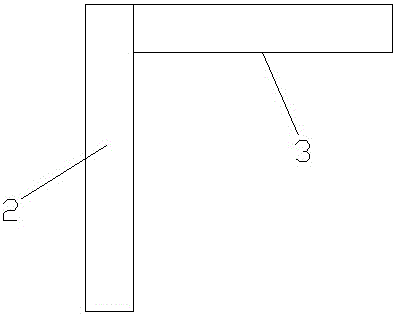

[0013] Such as Figure 1-Figure 2 As shown, an environmentally friendly floor includes a polyurethane coating layer 1, a first bamboo board layer 2, a second bamboo board layer 3, a fir layer 4, and a high-density fiber board layer 5. The second bamboo board layers 3 are mutually clamped and connected , The two ends of the second bamboo board 3 are provided with protrusions and grooves, so that the second bamboo board 3 can be clamped in sequence, and the same connection method is adopted between the first bamboo board layers 2. The first bamboo board layer 2, The second bamboo board layer 3 and the fir layer 4 are bonded with epoxy resin. The polyurethane coating layer 1, the first bamboo board layer 2, the second bamboo board layer 3, the fir layer 4 and the high-density fiberboard layer 5 are arranged in sequence from top to bottom, the polyurethane coating layer 1 is coated on the first bamboo board layer 2, the first bamboo board layer 2 and the second bamboo board layer 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com