Lacquer stirring barrel capable of accurately controlling discharging amount and working method thereof

A technology of precise control and discharge volume, applied in mixer accessories, chemical instruments and methods, mixers with rotating mixing devices, etc. The overall structure is stable and reliable, the installation is firm and reliable, and the use flexibility is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

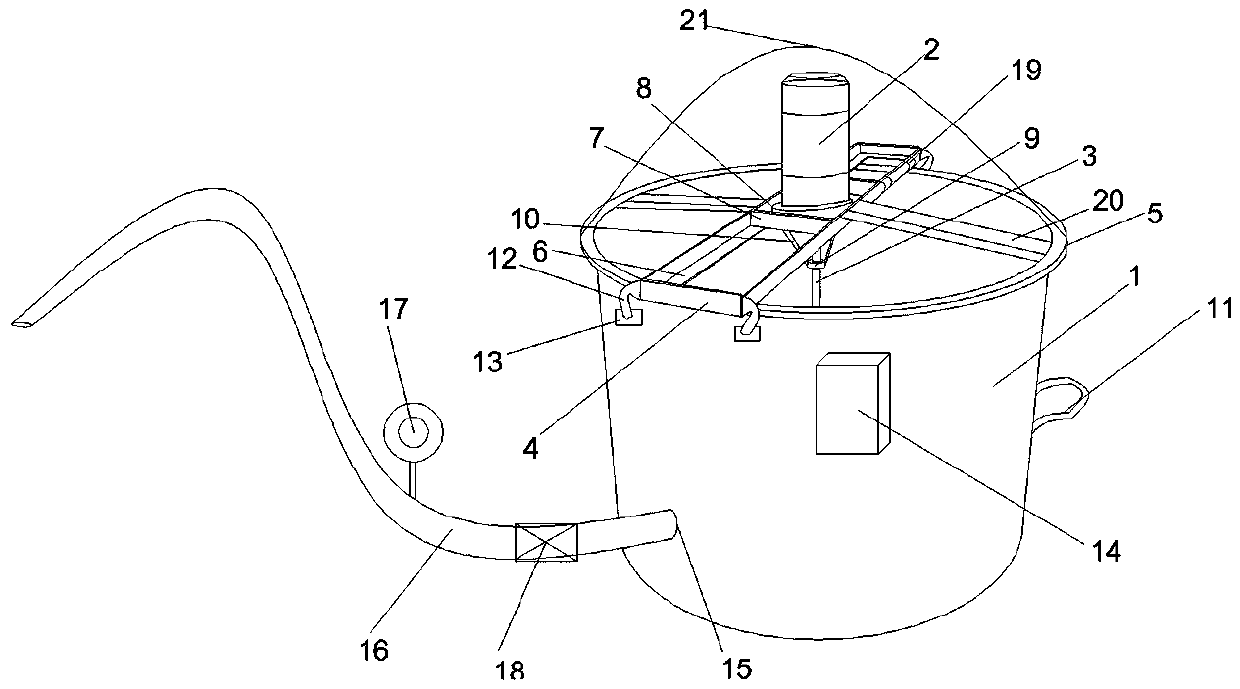

[0032] Such as figure 1 As shown, a latex mixing tank that can accurately control the output includes a tank body 1, a stirring motor 2 installed on the top of the tank body 1, a stirring shaft 3 connected to the stirring motor 2, and a stirring shaft connected to the stirring shaft 3. A number of stirring blades. A discharge port 15 is provided on one side of the bottom of the barrel body 1, a discharge pipe 16 connected to the next process is provided on the discharge port 15, a flow meter 17 is provided on the discharge pipe 16, and a PLC controller is provided on the front of the barrel body 1 14. A solenoid valve 18 is provided near the discharge port 15 on the discharge pipe 16, the flowmeter 17 is connected to the signal receiving end of the PLC controller 14, and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com