H-shaped fiber reinforced plastic grating construction site temporary pavement and construction method

A construction site, glass fiber reinforced plastic technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of inability to meet the turnover use, need frequent maintenance, unfavorable environmental protection, etc., and achieve environmental protection, high construction efficiency, and high turnover utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

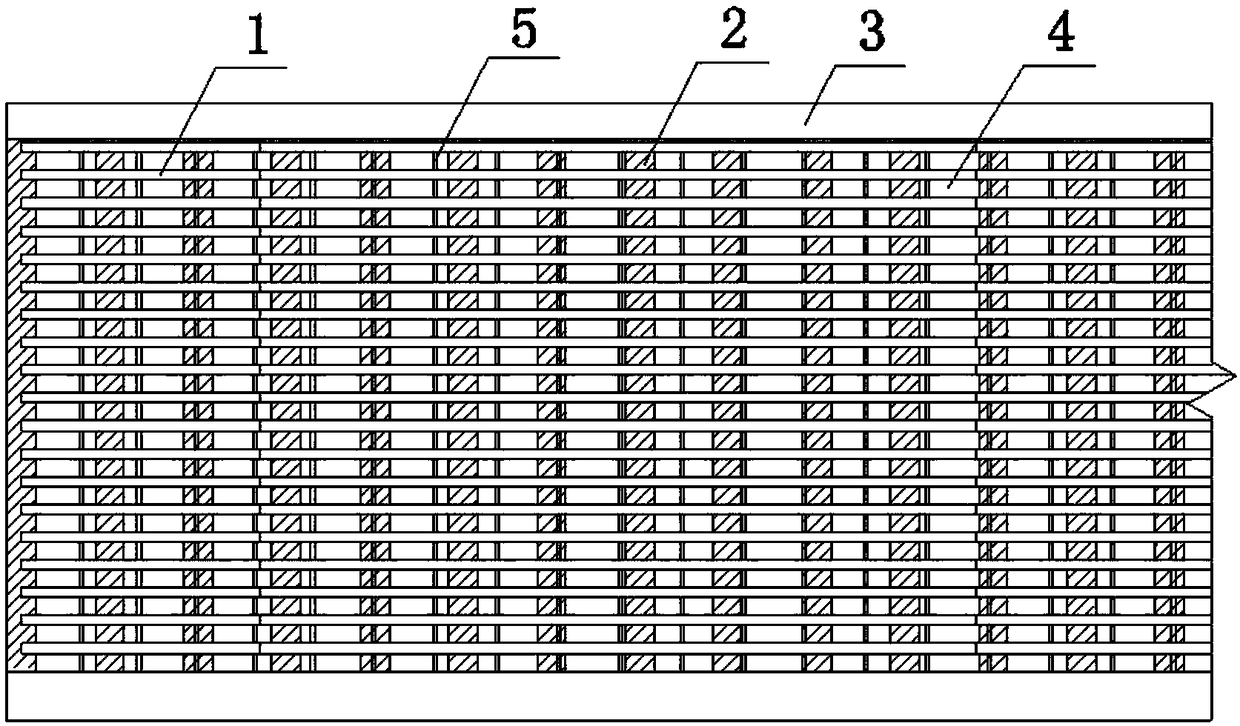

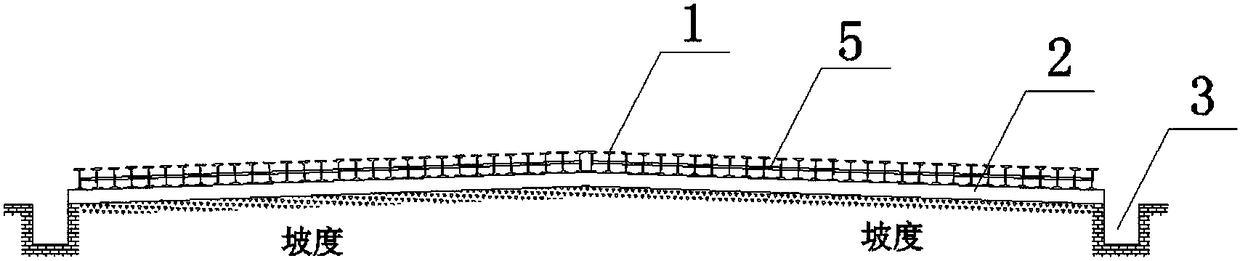

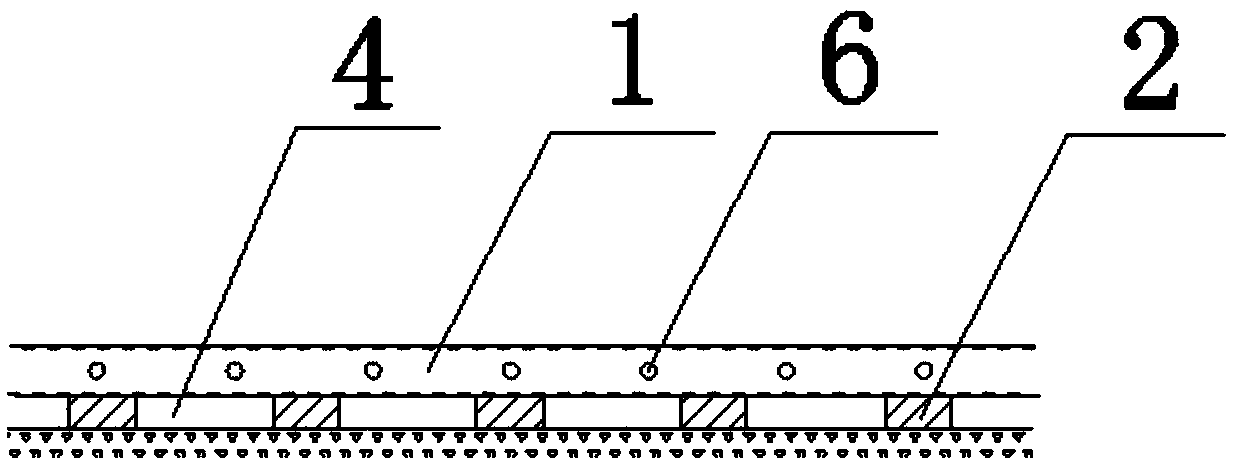

[0019] Embodiment of the present invention: the structure diagram of the temporary pavement at the construction site made of I-shaped glass fiber reinforced plastic grid is as follows Figure 1~3 As shown, it includes 10 rows of supporting piers 2 arranged at a distance of 40 cm. On the supporting piers 2, 20 rows of fiberglass main girders are laid at a distance of 20 cm. FRP girders 1 are connected by mortise and tenon structure 7. On each row of FRP girders, there are through holes 6 at intervals of 20 cm. Connecting rods 5 pass through the through holes 6 on each row of FRP girders and connect each row of FRP girders. Connect together to form a whole I-shaped FRP grid to make temporary pavement on the construction site. A road drainage ditch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com