Constant-temperature liquid-liquid equilibrium separation unit

A liquid-liquid balance and separation device technology, applied in liquid separation, liquid separation auxiliary equipment, separation methods, etc., can solve problems such as unfavorable two-phase liquid balance, easy to break, difficult processing, etc., to achieve easy separation simulation test, strong stainless steel , good airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

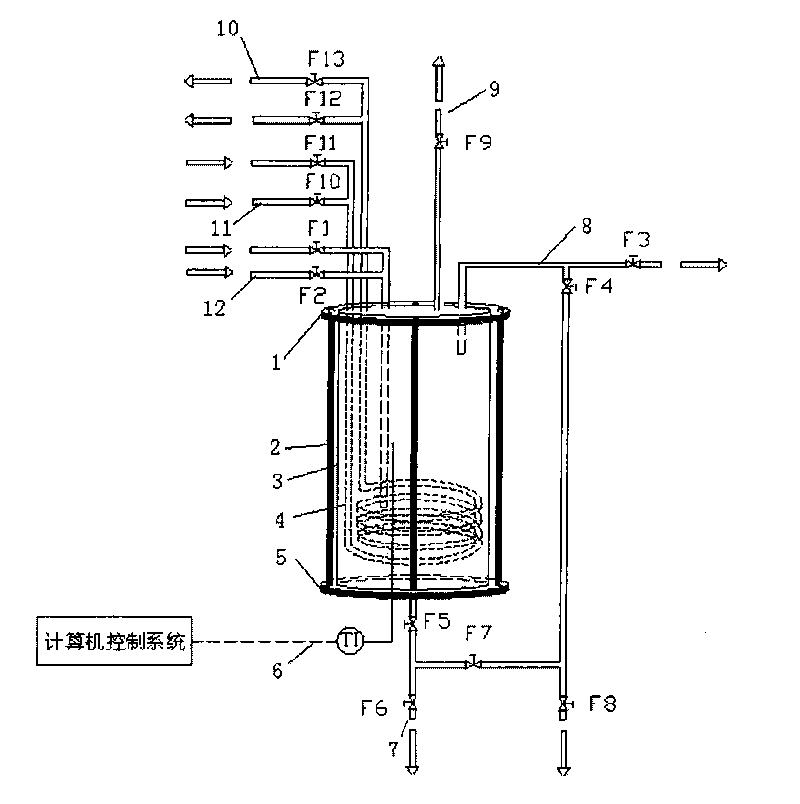

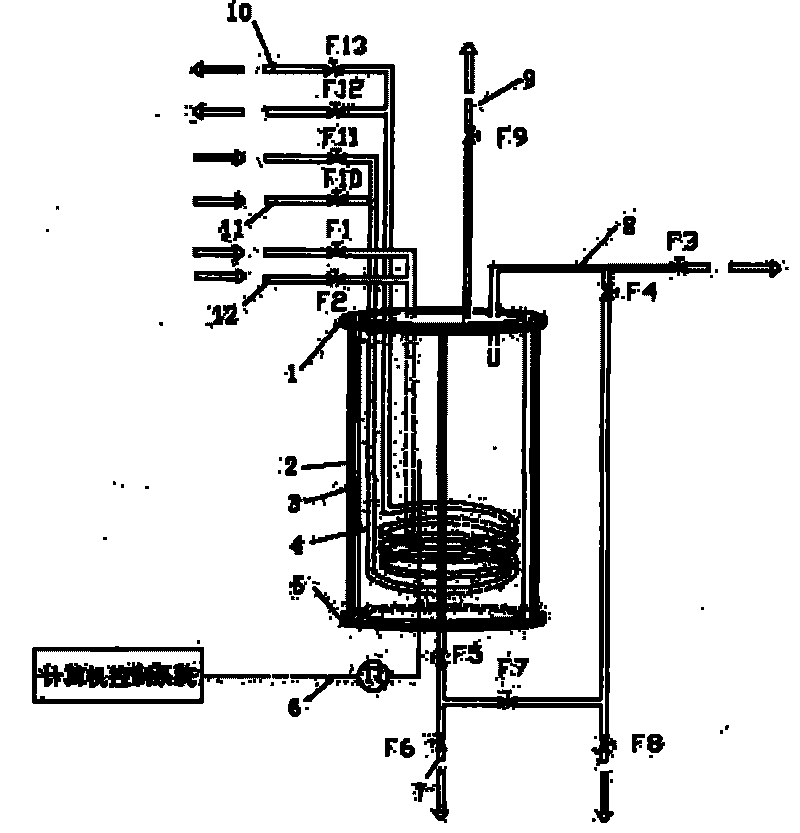

[0014] Constant temperature liquid-liquid balance separation device, including cover 1, cylindrical shell 3, bottom 5, cooling coil 4 and temperature control device 6, characterized in that: the cover 1, cylindrical shell 3, bottom 5 They are tightly fitted to each other in turn, and are tightly connected by fixing bolts 2 . Sealing rings are placed between the cover 1 and the cylindrical casing 3 , and between the bottom 5 and the cylindrical casing 3 .

[0015] The cover 1 and the bottom 5 are made of stainless steel. The cylindrical housing 3 is made of transparent organic glass.

[0016] The cylindrical casing 3 is built with a spiral cooling coil 4 , and the inlet and outlet pipes of the coil are led out from the cover 1 respectively. The inlet and outlet pipes of the coil are divided into two paths, and the inside of the container is respectively connected with two paths of cooling medium of different grades. The two paths of cooling medium outlet 10 and the two paths ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com