Patents

Literature

36results about How to "Good heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

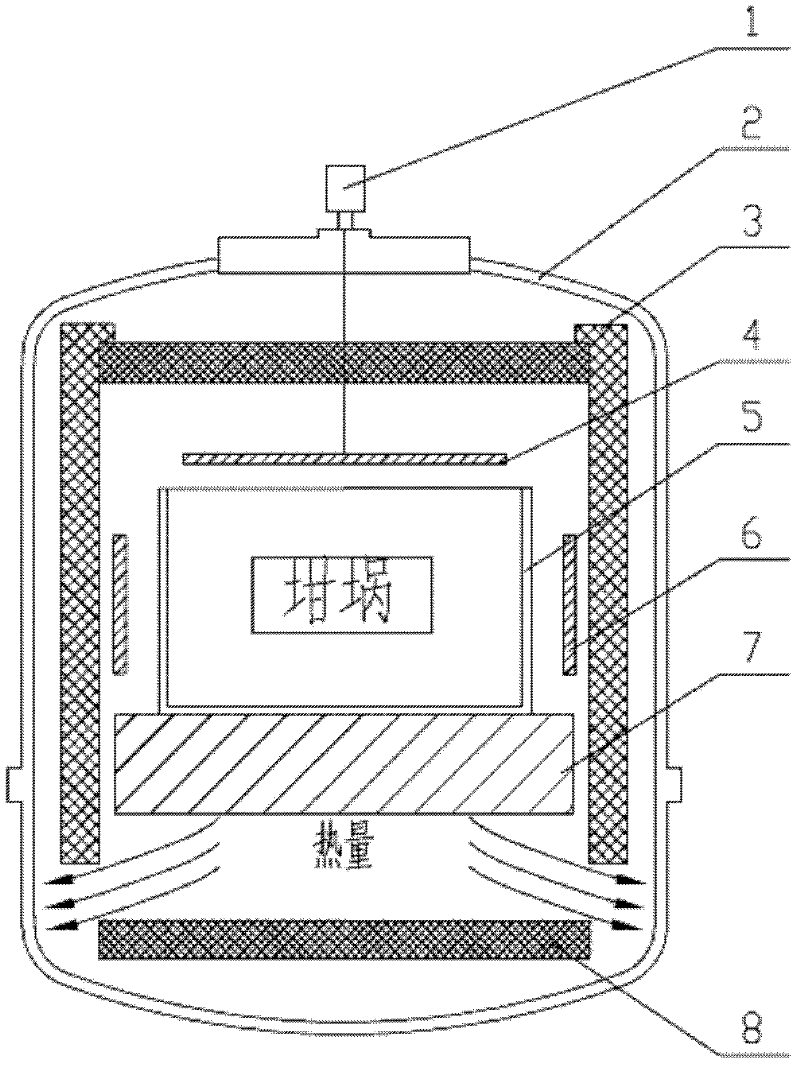

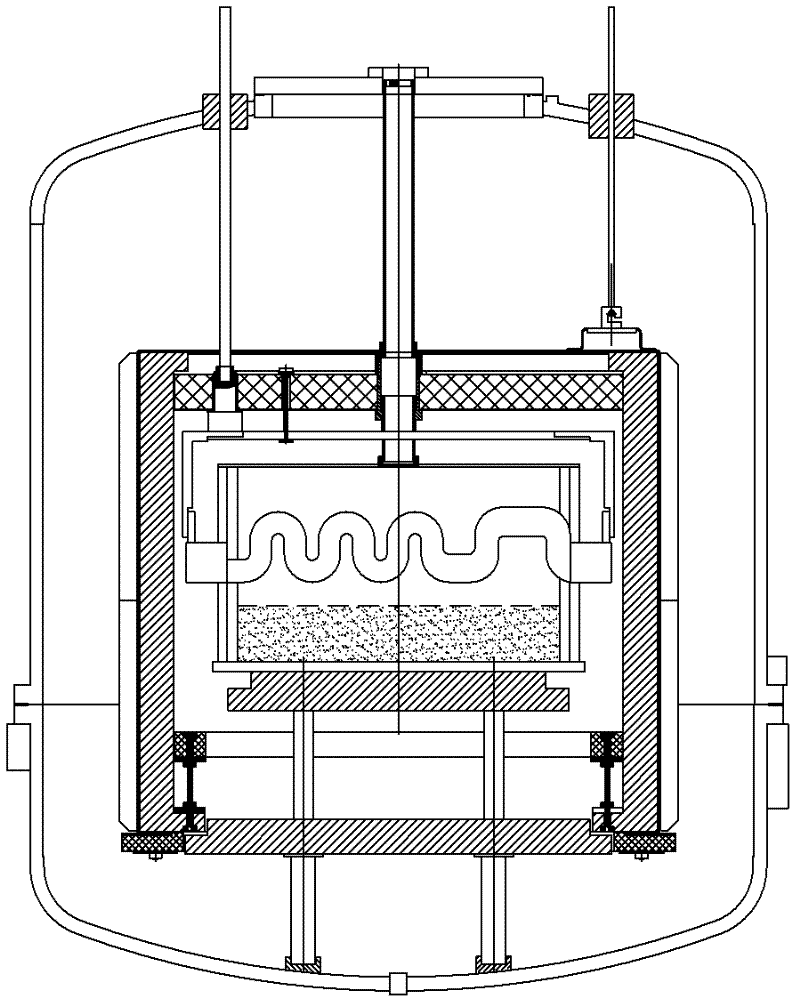

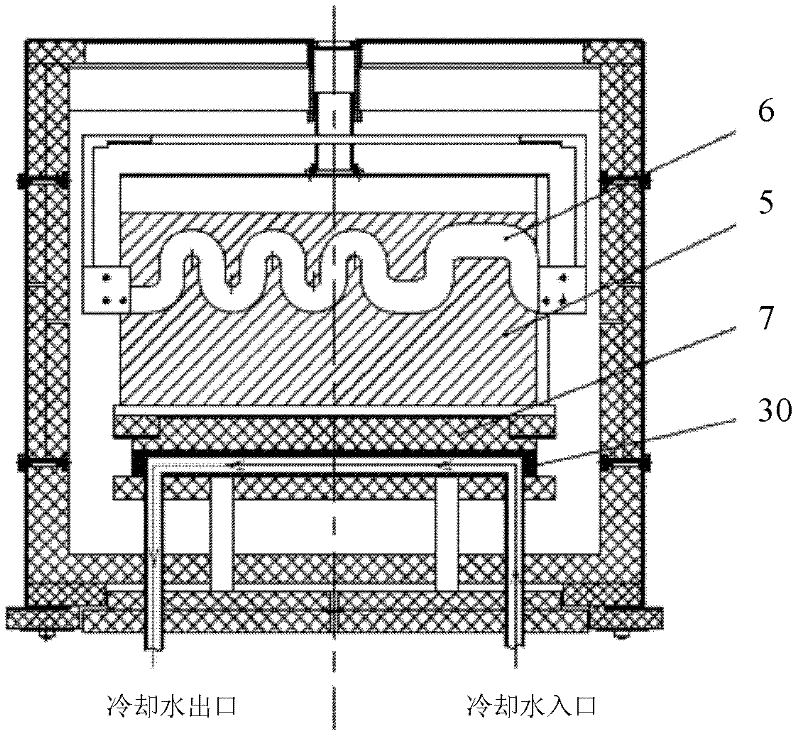

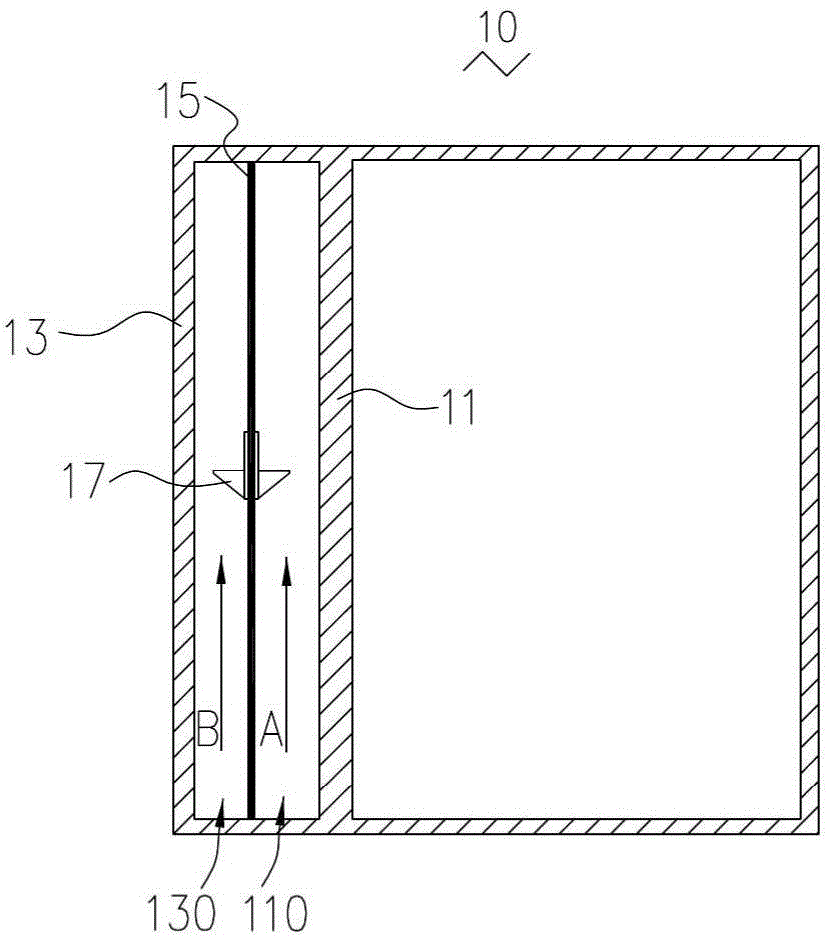

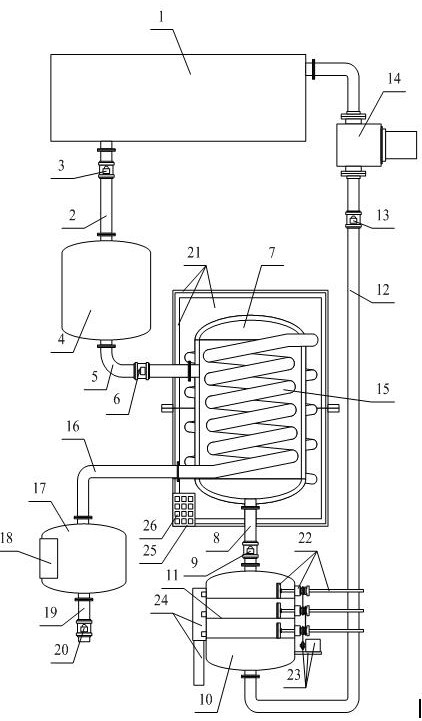

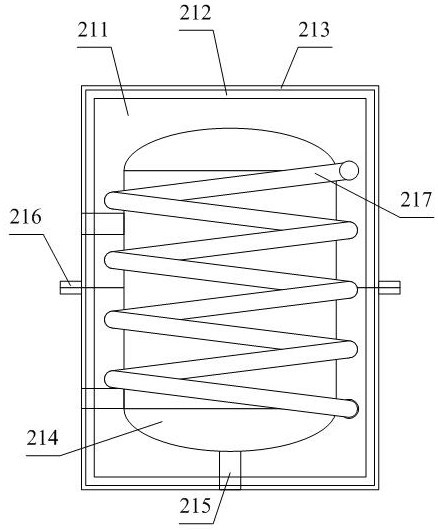

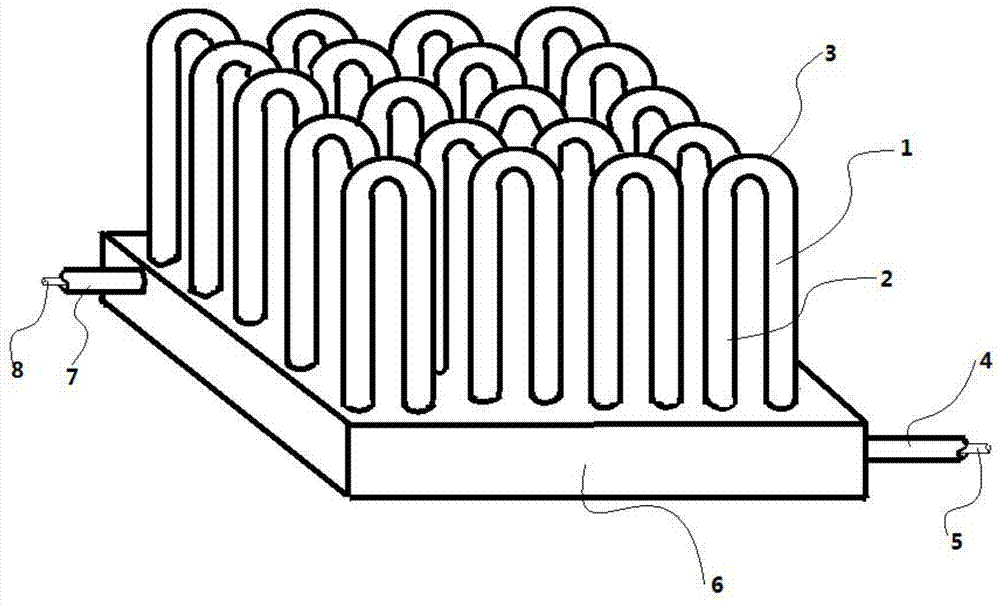

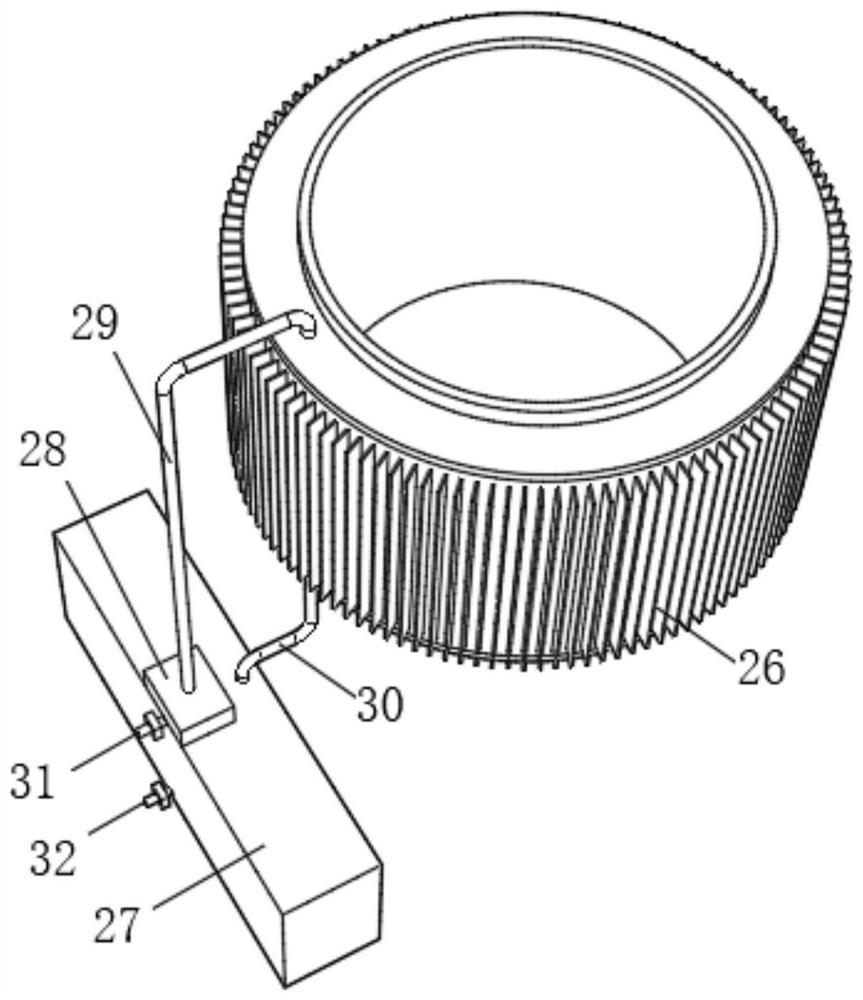

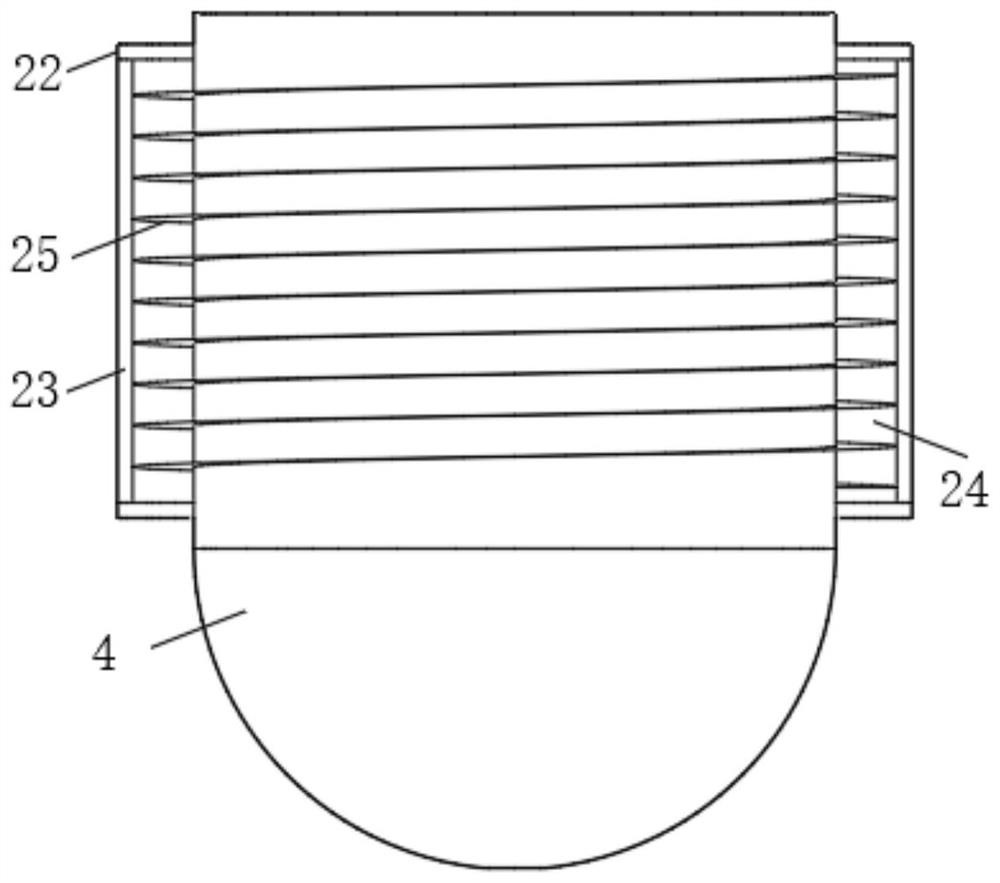

Closed cooling system of gas cooled polysilicon ingot furnace

ActiveCN102234837APrecise temperature controlEasy to controlPolycrystalline material growthSingle crystal growth detailsNuclear engineeringCrucible

The invention relates to the manufacture technical field of polysilicon ingot furnaces, and aims to provide a closed cooling system of a gas cooled polysilicon ingot furnace. The system comprises a heat exchange platform positioned on a supporting column and used for placing a crucible, wherein a cooling gas channel is arranged in the heat exchange platform; a gas inlet and a gas outlet at two ends of the cooling gas channel are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline; and the heat exchange platform, the cooling gas inlet pipeline, the cooling gas outlet pipeline, a cooling gas power pump group and a cooler form a closed circulation loop of the cooling gas. Compared with the cooling method of radiation cooling and water cooling, the system related by the invention has strong gas cooling control capacity and high industrial controllability; the gas is fed into the heat exchange platform evenly, so that the whole temperature of the heatexchange platform is even, which is in favor of even nucleation of a silicon melt at the bottom of the crucible; and the reducing speed of the temperature at the bottom of the crucible can be precisely controlled during the crystal growth.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

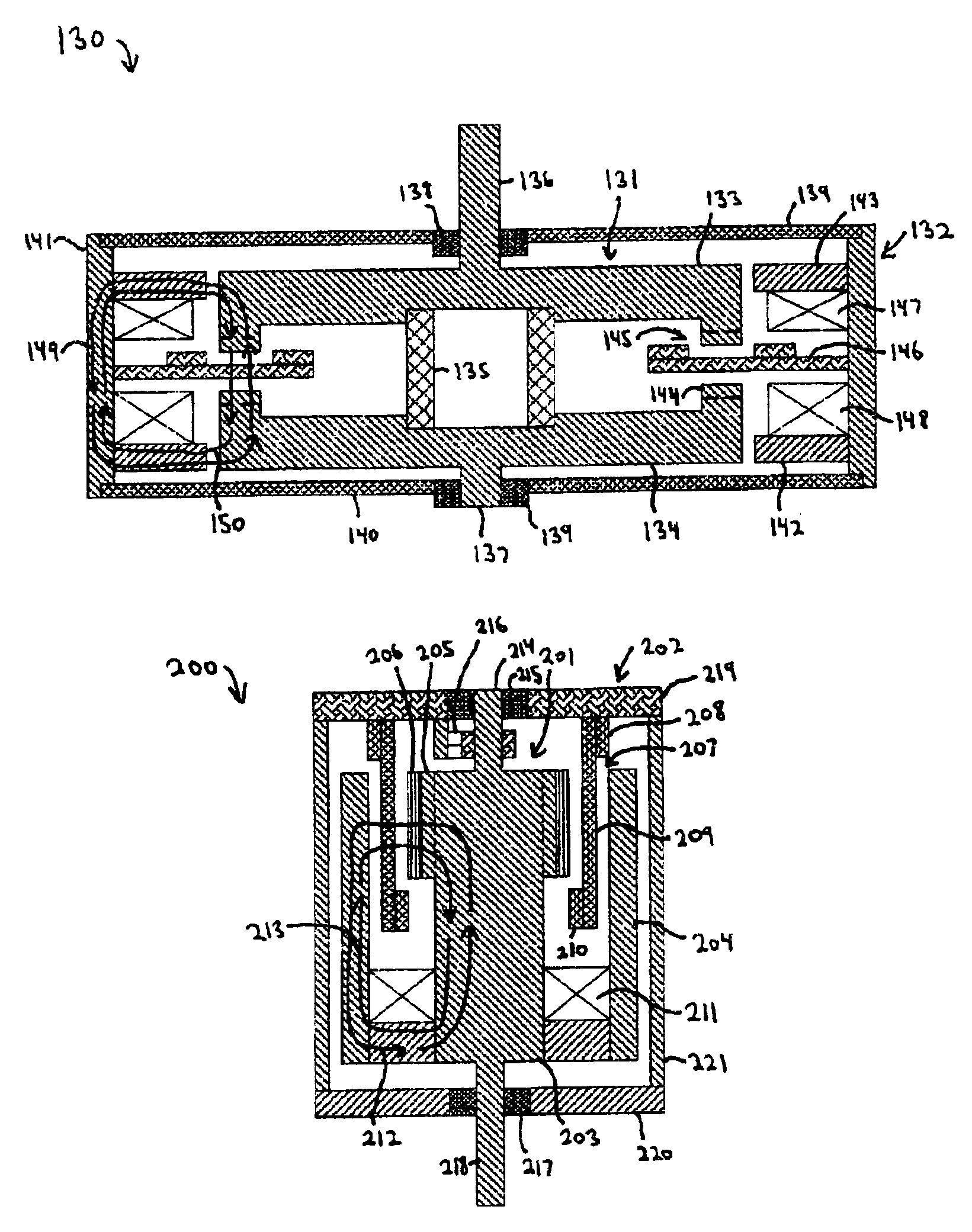

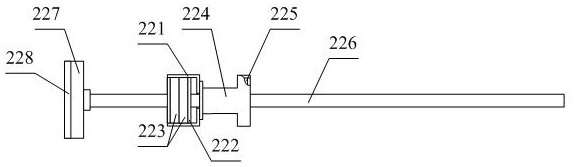

Compact heteropolar hybrid alternator-motor

InactiveUS7105979B1Good heat transferSpeed capability be reduceWindingsMagnetic circuit rotating partsDynamoEngineering

A brushless hybrid electrical machine for converting between electrical and mechanical energy has a rotor supported for rotation about an axis of rotation relative to a juxtaposed stator that is stationary and magnetically interacts with the rotor. The rotor includes a ferromagnetic rotor structure having two portions spaced apart, but rotating together, and defining therebetween an armature air gap. Magnetic poles are arranged in a circumferentially alternating array of ferromagnetic and permanent magnet poles, bordering the air gap. A stationary air core armature having multiple phase windings is located in the armature air gap, and a field coil is also positioned between the two portions of the rotor for generating field coil flux that flows in a flux path through the ferromagnetic poles, the armature air gap and through the ferromagnetic rotor structure. The permanent magnet poles generate permanent magnet flux that also flows in a flux path through the armature air gap and through the ferromagnetic rotor structure. The field coil flux and the permanent magnet flux induces an AC voltage in the multiple phase windings of the air core armature as said rotor rotates.

Owner:REVOLUTION ELECTRIC MOTOR +1

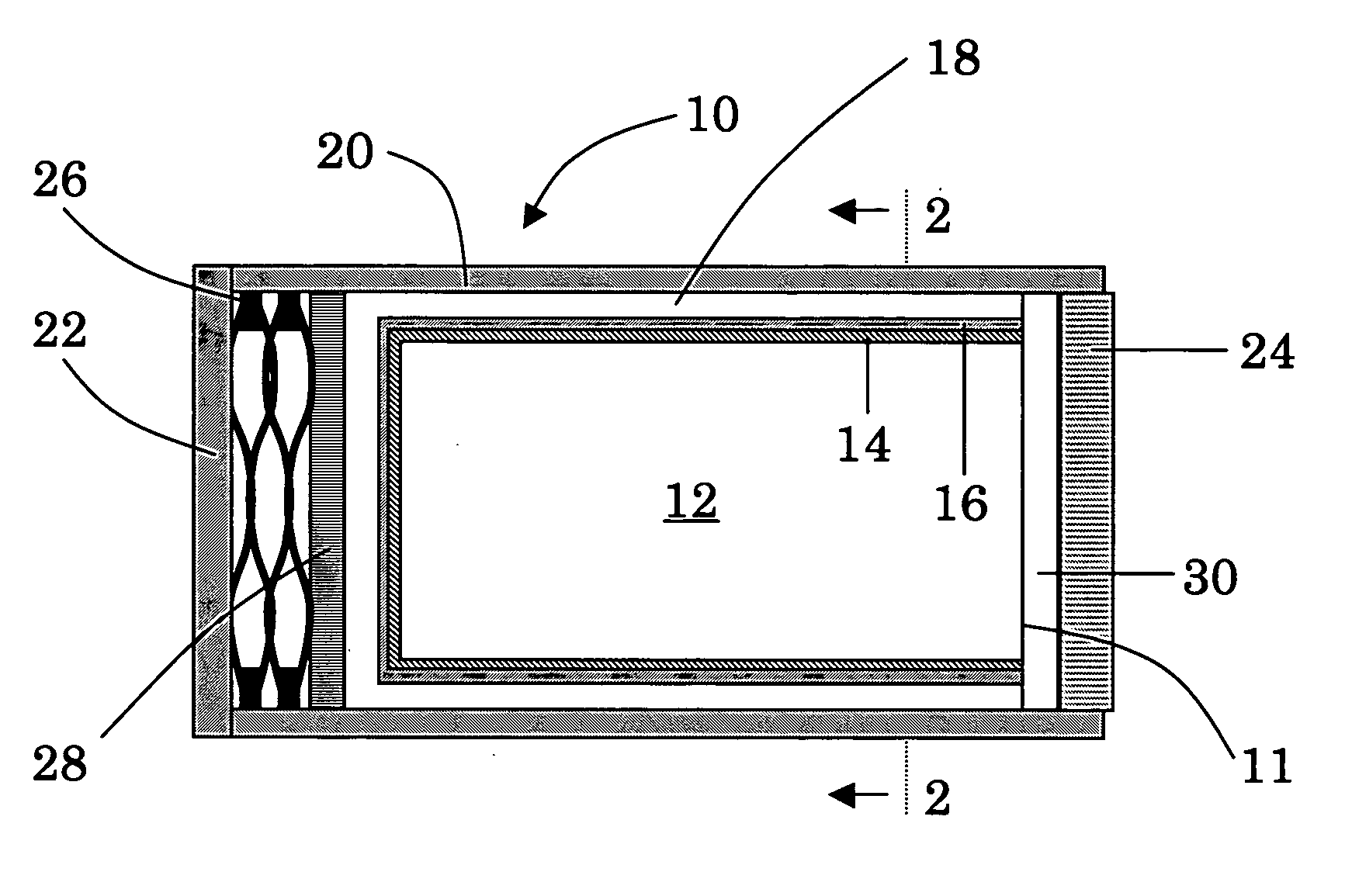

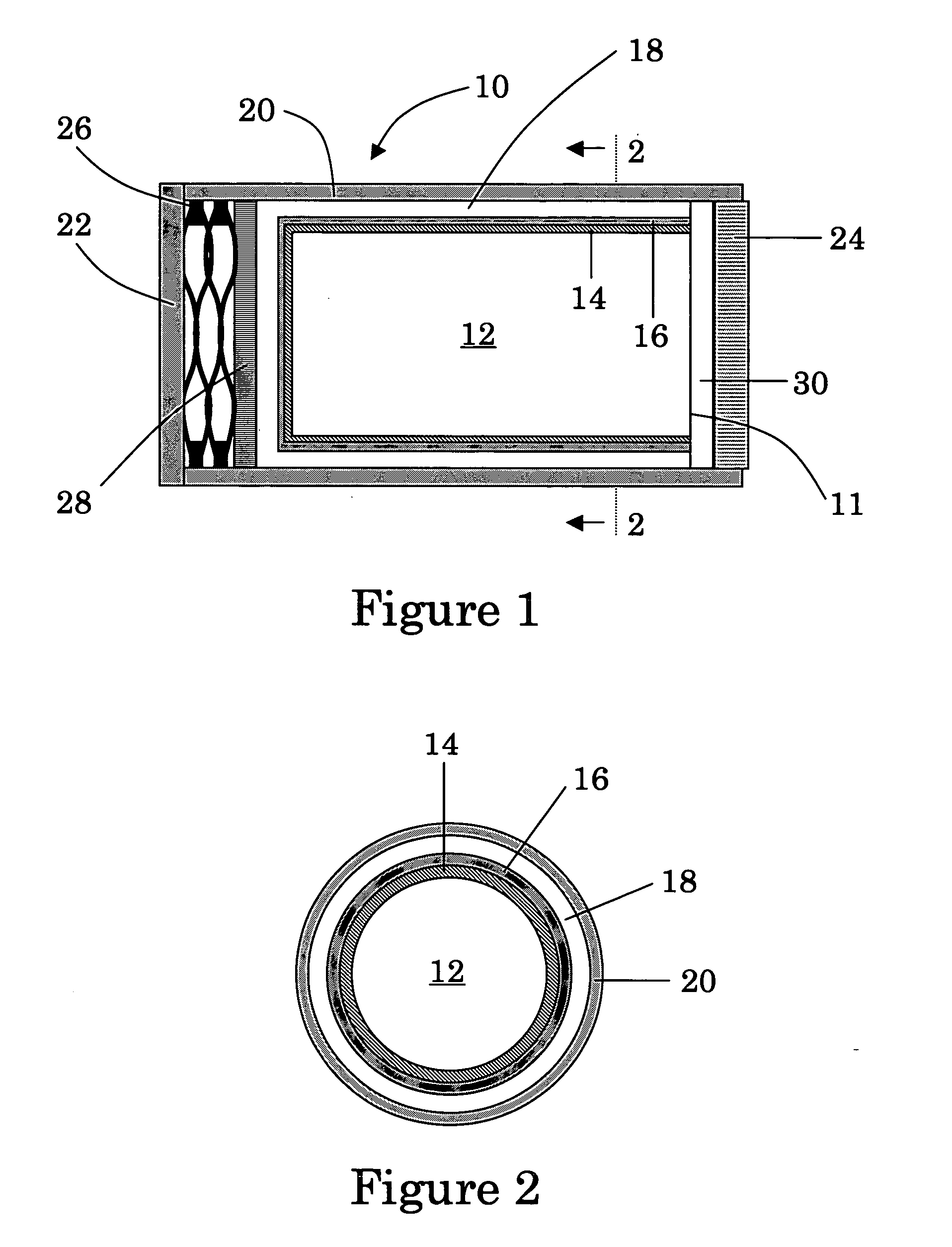

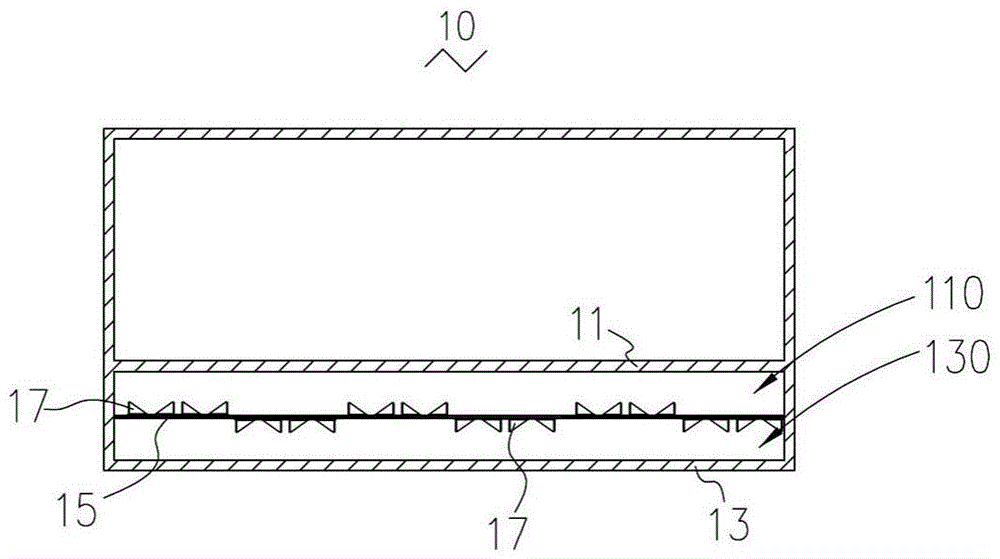

Covering of scintillation detector with a reflective coating

InactiveUS20060091312A1Good heat transferInhibition effectMaterial analysis by optical meansRadiation intensity measurementPhysicsScintillation crystals

The present invention discloses a scintillation detector 10 comprising a scintillation crystal 12 covered by an inner coating layer 14, said inner coating layer 14 being reflective to light spectrum, and said inner coating layer 14 being stuck directly to said crystal by a chemical and / or a physical binding. According to further aspect of the invention, a method is disclosed to measure radiation from an wellbore environment with the aforementioned scintillation detector 10. According to a still further aspect of the invention, a method is disclosed to manufacture a scintillation detector 10, comprising the steps of: defining two surface parts in a scintillation crystal 12: first and second part, covering said first part of said scintillation crystal 12 with an inner coating layer 14, said inner coating layer 14 being reflective to light spectrum and said inner coating layer 14 being stuck directly to said crystal 12 by a chemical and / or a physical binding, leaving said second part without coating, positioning said scintillation crystal 12 and said inner coating layer 14 in a shock absorbing member 18, positioning said second part in front of an optical window 24 transmissive to scintillation light given by said scintillation crystal 12, positioning said shock absorbing member 18 and said optical window 24 in a protective housing 20.

Owner:SCHLUMBERGER TECH CORP

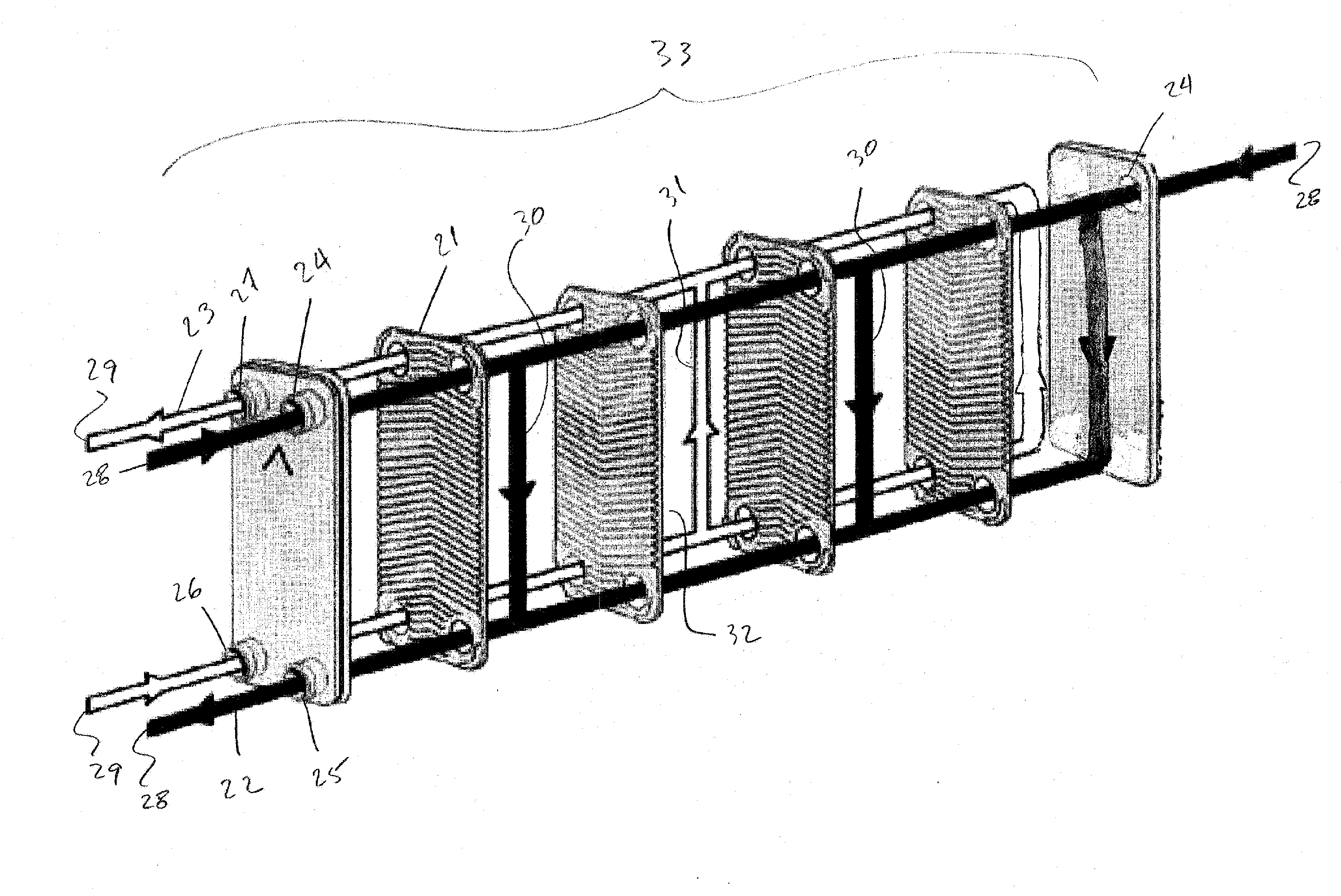

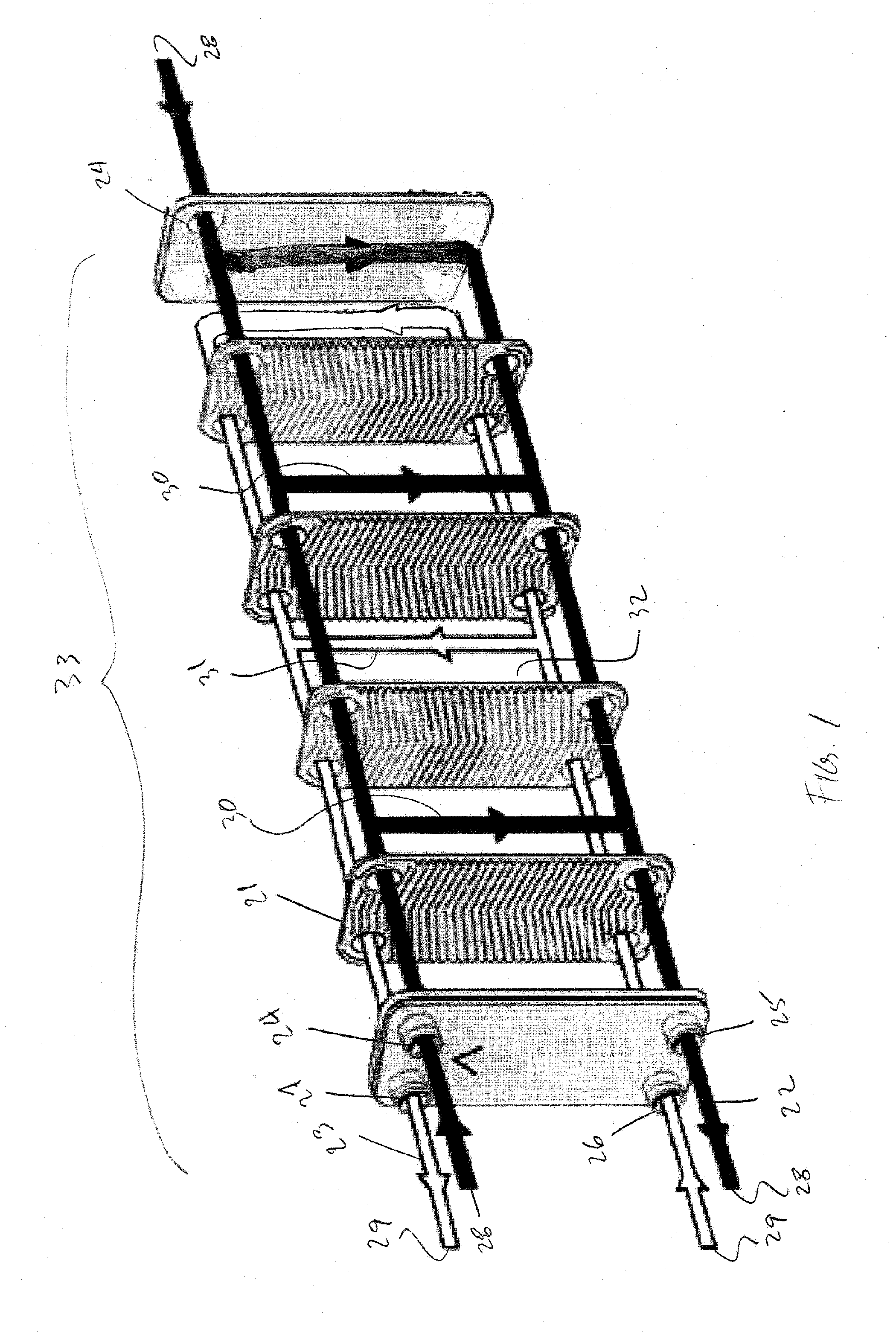

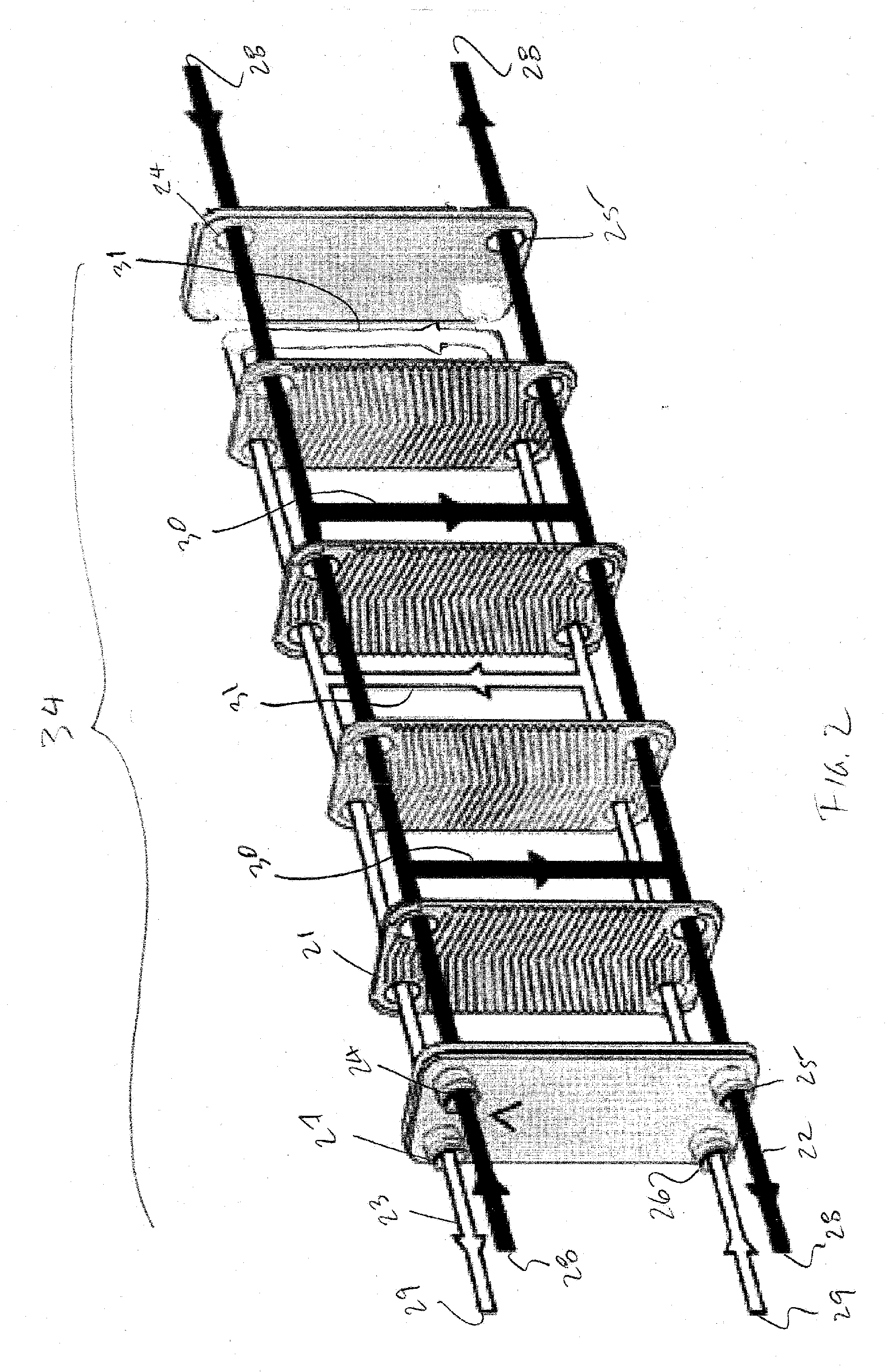

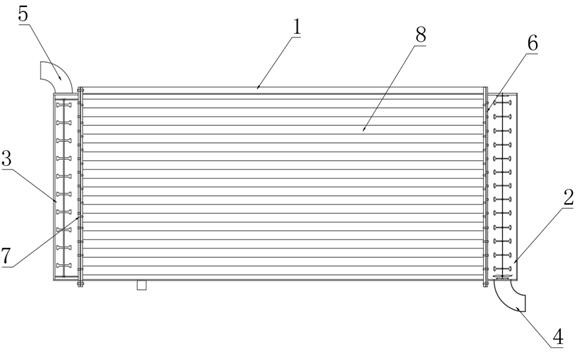

Double inlet heat exchanger

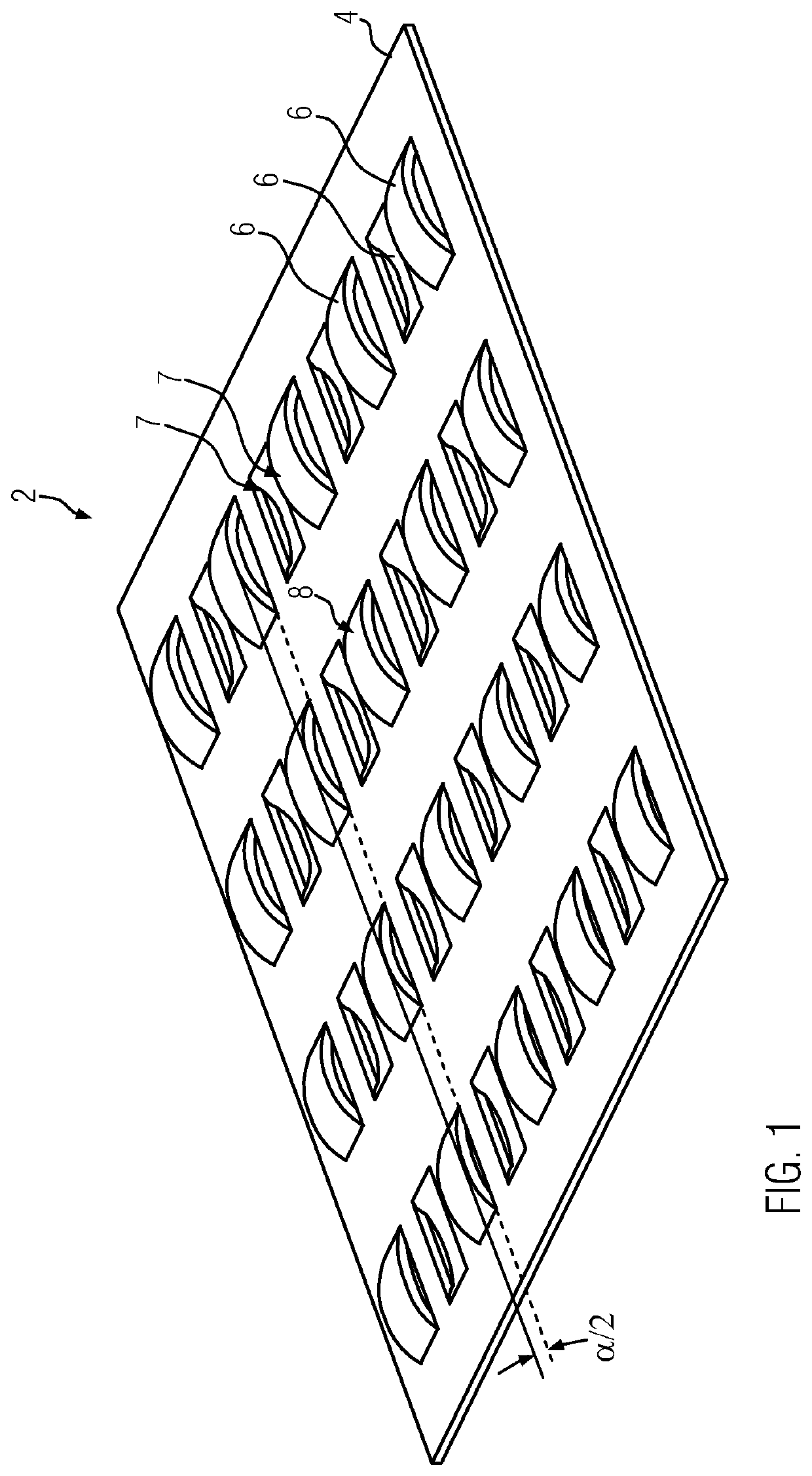

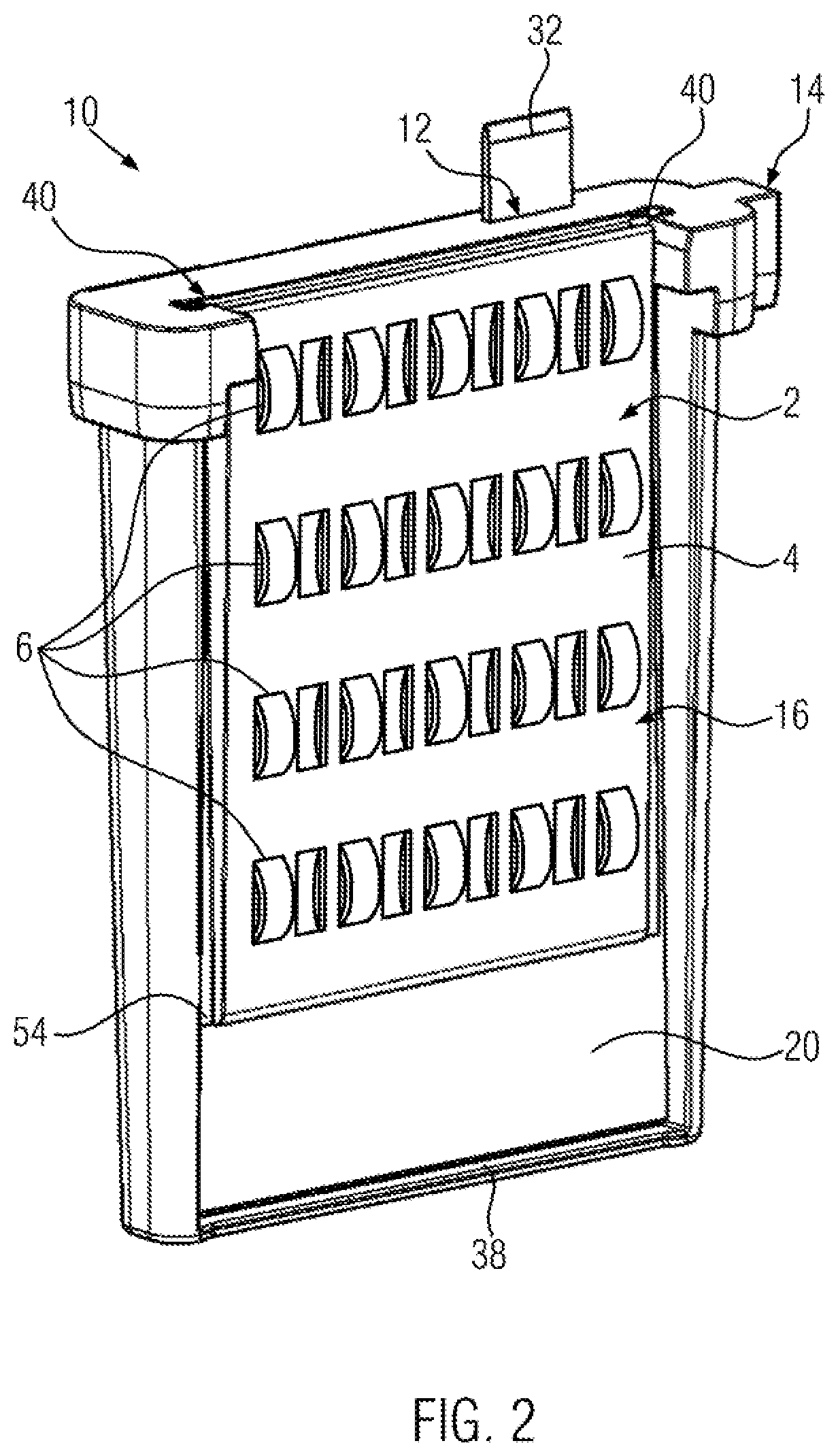

InactiveUS20100065262A1Good heat transferIncrease fluid velocityStationary tubular conduit assembliesLaminated elementsRefrigerantEngineering

The present invention is a plate heat exchanger that allows refrigerant to enter the heat exchanger simultaneously from two sides. Allowing the refrigerant or other fluid to enter from two sides splits the flow and improves fluid velocities by presenting an optimized area to the fluid flow. This effect may be realized for both gases and liquids, and for example with respect to a liquid refrigerant, where it enters the heat exchanger simultaneously by splitting. According to the present invention the split liquid flow from the condenser feeds dual electronically controlled expansion valves before entering the heat exchanger. Fully evaporated gas leaves the heat exchanger through a single outlet, or through a dual outlet.

Owner:MULTISTACK

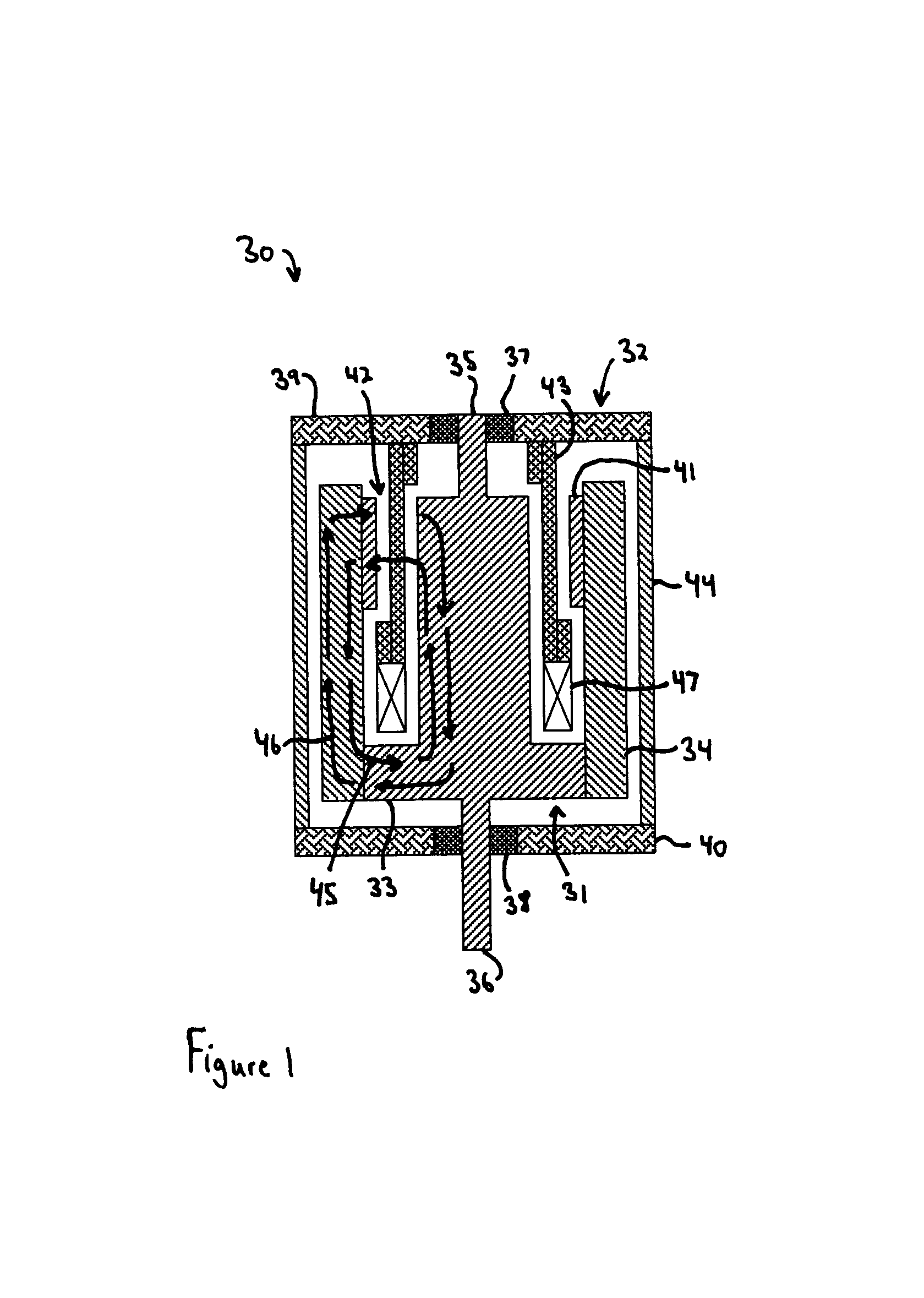

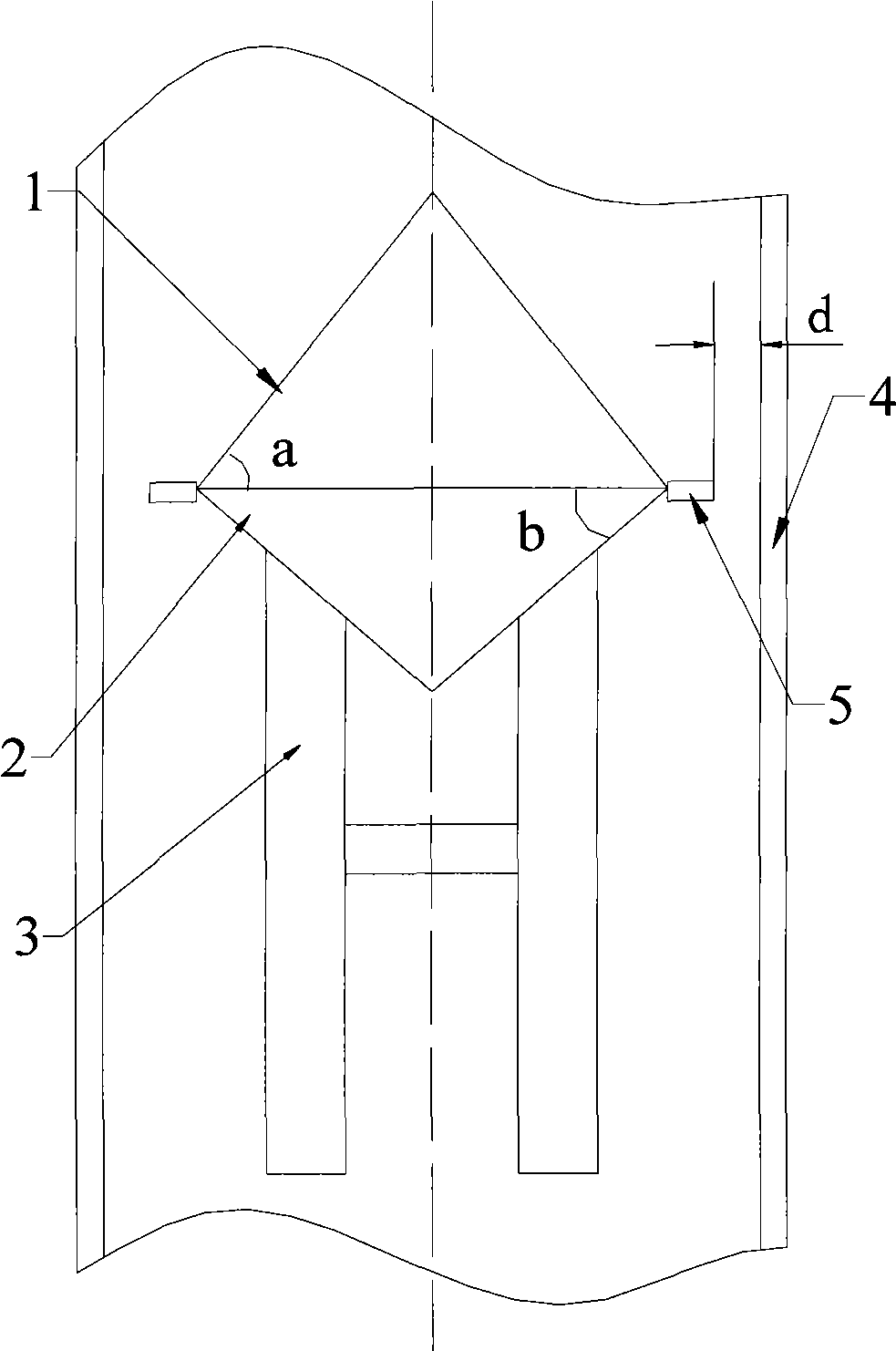

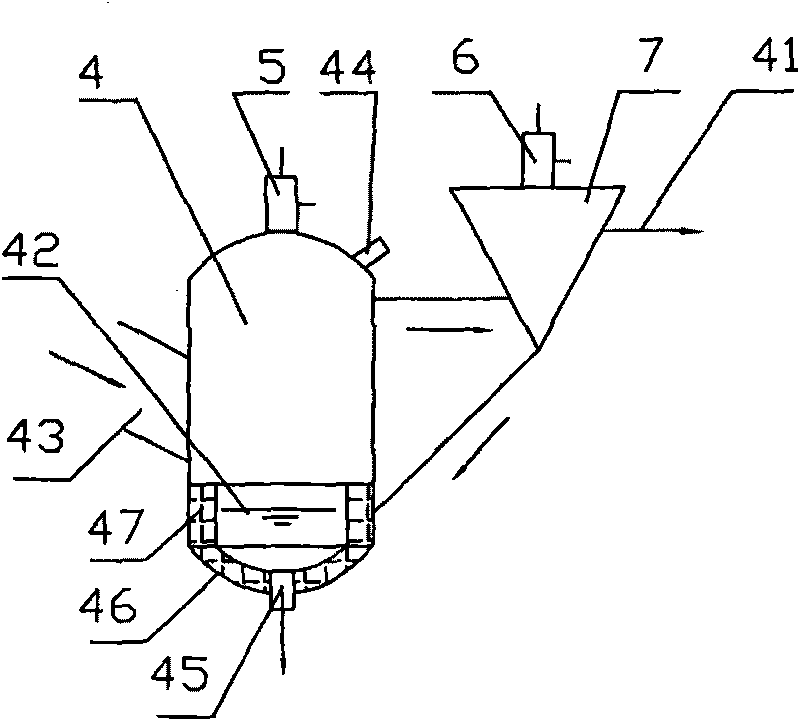

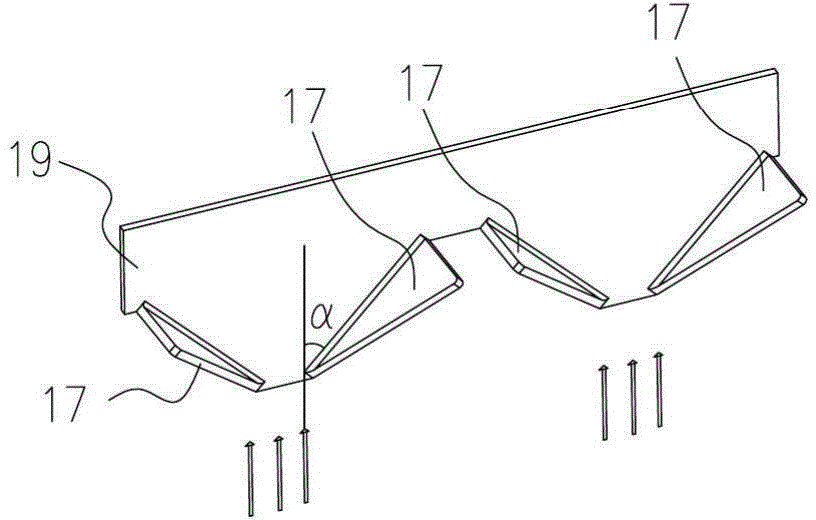

Cone gas distributor for fluidized bed

InactiveCN101497015AImprove the uniformity of gas distributionGood heat transferCarburetting by solid carbonaceous material pyrolysisCombined combustion mitigationEngineeringFluidized bed

The invention relates to a gas distributing device for a fluidized bed, which is arranged in a gas gathering chamber 4. The gas distributing device comprises an upper cone, a lower cone and a bracket, wherein the bracket is inversely provided with the lower cone; the lower cone is provided with the upper cone; the bottom surface of the upper cone is opposite to that of the lower cone; and the upper cone and the lower cone have the same bottom diameter, and the bottom diameter is less than the inner diameter of the gas gathering chamber. The bottom angle a of the upper cone is between 30 and 55 DEG; the bottom angle of the lower cone is between 28 and 48 DEG; and the bottom radius of the upper cone and the lower cone is 2 to 20 mm less than the inner diameter of the gas gathering chamber. The cone gas distributing device has good gas distributing effect and effectively improves the gas distributing evenness; the cone surface has the advantages of smoothness, no gas channel, small pressure drop, abrasion resistance and difficult deformation at a high temperature; an annular gap can effectively prevent impurities carried by a raw material from blocking the gas distributing device so as to conveniently carry out replacement or maintenance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

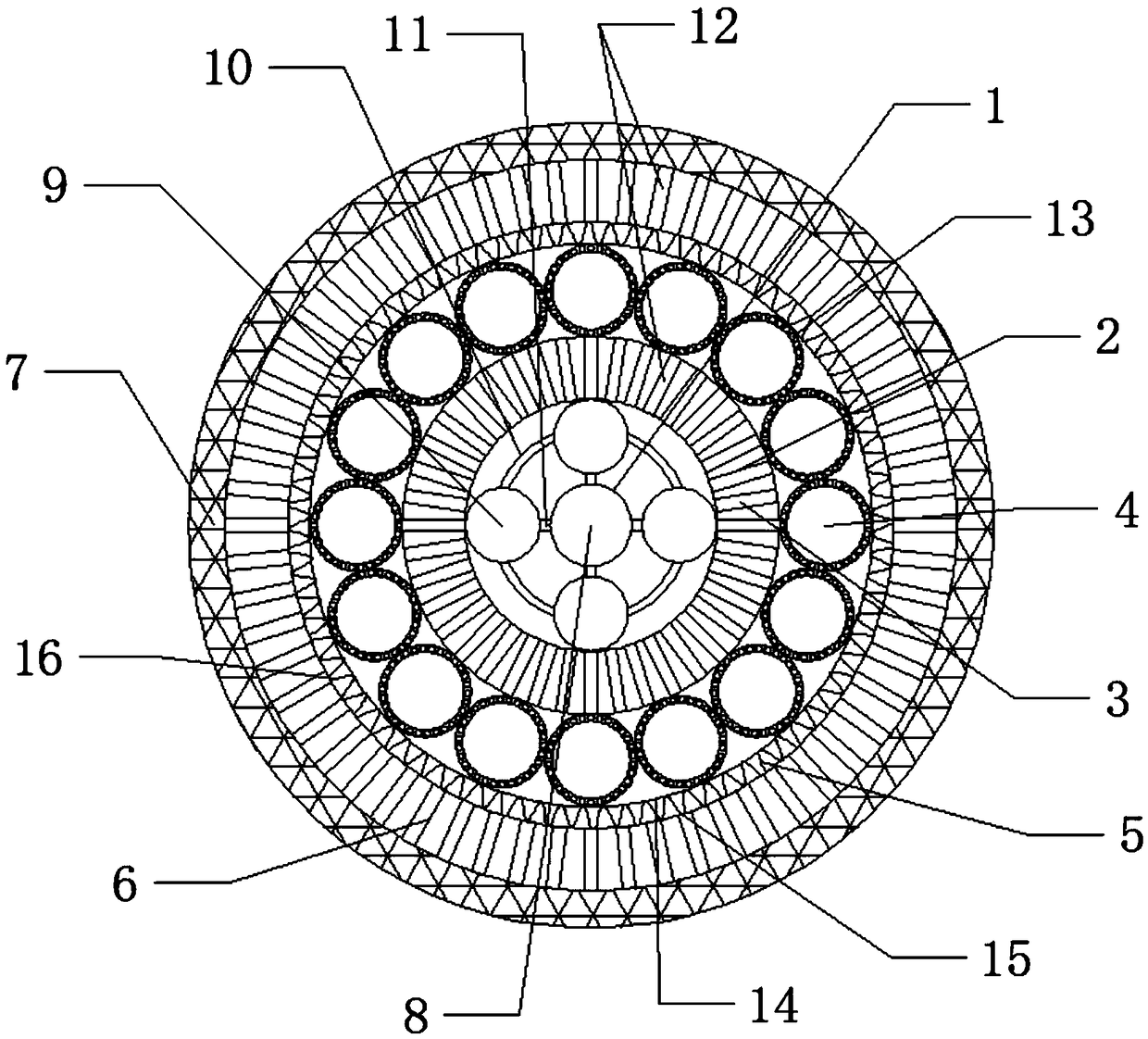

Flexible cable with heat dissipation effect

InactiveCN108735353ASafeguard ResilienceImprove toughnessFlexible cablesFlexible conductorsEngineeringElectric cables

The invention discloses a flexible cable with a heat dissipation effect, belongs to a multifunctional cable in the technical field of cables and aims at providing the flexible cable with the heat dissipation effect. According to the technical scheme, the flexible cable comprises a flexible cable core group arranged in the middle, wherein a first heat dissipation grid tube group is arranged outsidethe flexible cable core group; the length directions of grid tubes in the heat dissipation grid tube group are set along the radial direction of the flexible cable core group; a plurality of elasticcables are arranged outside the first heat dissipation grid tube group and are uniformly distributed along the external circumferential direction of the first heat dissipation grid tube group; a spring coil is arranged outside the elastic cables; a second heat dissipation grid tube group is arranged outside the spring coil; and a heat absorption layer is arranged outside the second heat dissipation grid tube group. The flexible cable with the heat dissipation effect has a good heat dissipation function while the flexibility of the cable is strengthened, and can be widely applied to a relatively harsh environment.

Owner:ZHENGZHOU JIZHI TECH CO LTD

Electromagnetic liquid heater

ActiveCN104132449AGood heat transferIncrease profitInduction heatingWater heatersEngineeringHeat conducting

The invention particularly discloses an electromagnetic liquid heater. The electromagnetic liquid heater comprises a non-magnetism receptor, a magnetism receptor, a magnetic coil, a heat conducting metal part and a control circuit. The non-magnetism receptor is used for accommodating to-be-heated liquid; the magnetism receptor capable of generating eddy currents with the magnetic coil is arranged in a cavity of the non-magnetism receptor; the magnetic coil acts on the magnetism receptor to enable the magnetism receptor to generate heat; the heat conducting metal part contacts with the magnetism receptor and is provided with a temperature probe used for temperature detection; the control circuit is used for controlling operation states of the magnetic coil and connected with the temperature probe. The electromagnetic liquid heater has the advantages that firstly, utilization rate of energy resources can be greatly improved, simple product structure is achieved, and market promotion is facilitated; secondly, due to the fact that the temperature probe and the heat conducting metal part are arranged on the magnetism receptor, the temperature can be further detected beneficially to prevent burning of the magnetism receptor.

Owner:李镇南

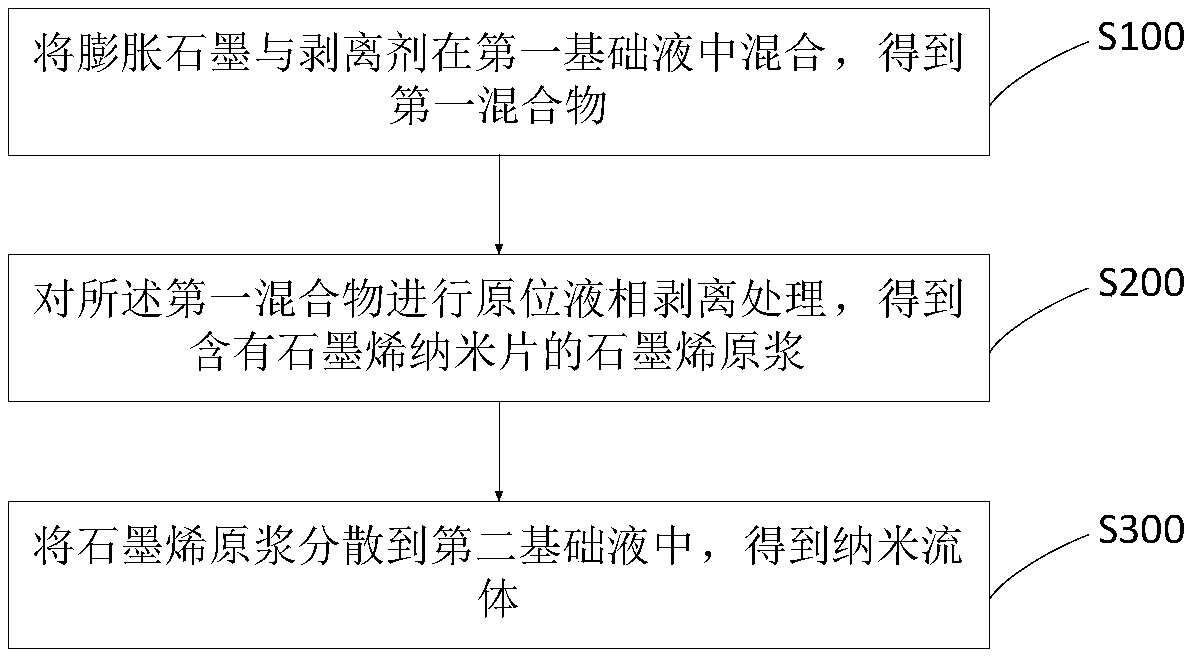

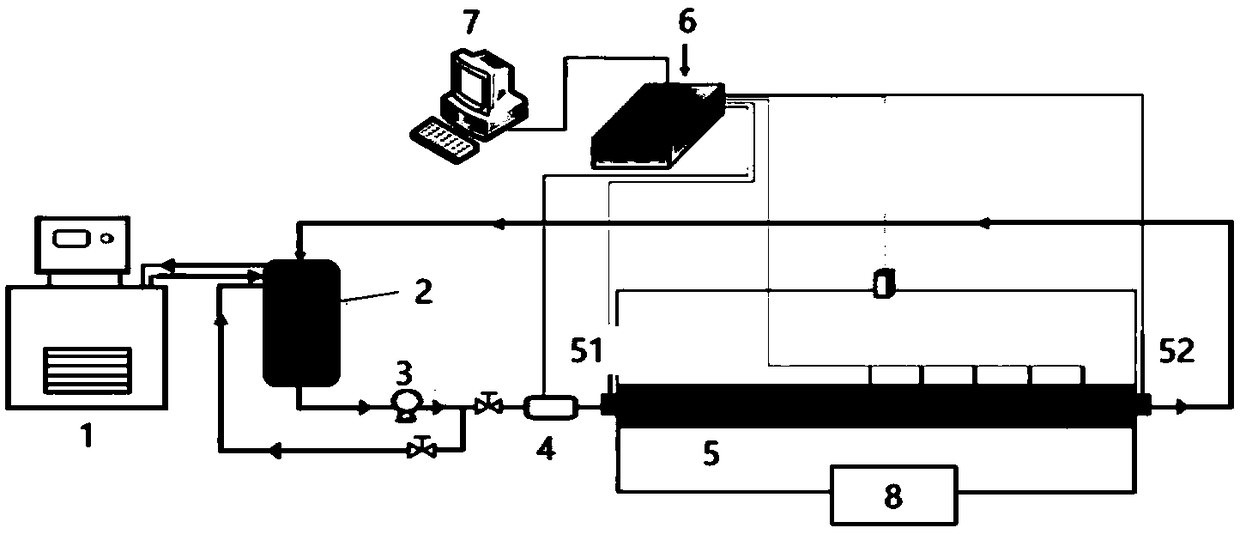

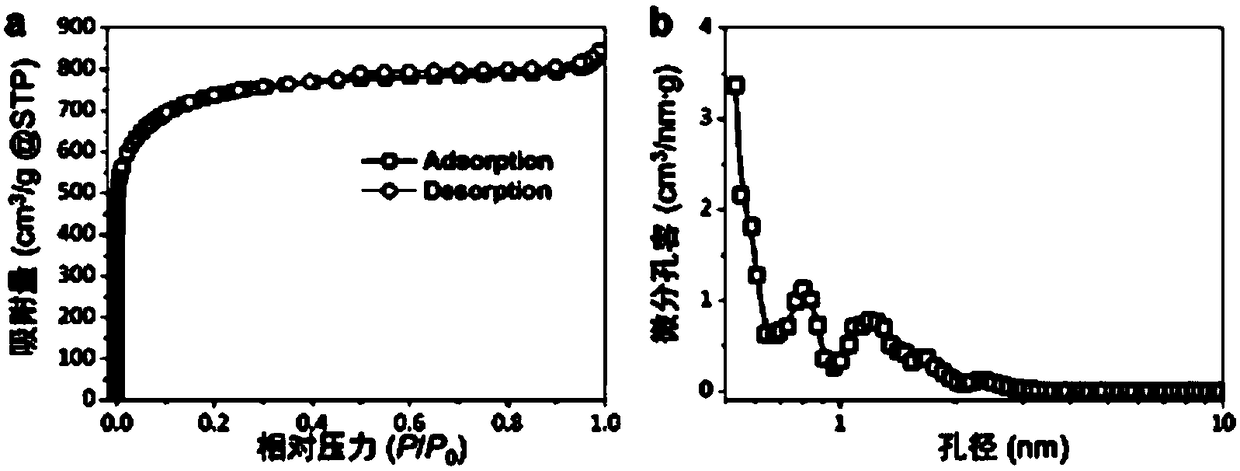

Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

The invention provides a nano-fluid, a preparation method thereof and a heat exchange device. The preparation method of the nano-fluid comprises the following steps: mixing expanded graphite with a stripping agent in a first base fluid to obtain a first mixture, and performing in-situ liquid phase stripping treatment on the first mixture to obtain a raw graphene stock containing graphene nano-sheets; and uniformly dispersing the raw graphene stock into a second base fluid to obtain the nano-fluid. The inventors have found that the method is simple and convenient to operate, facilitates large-scale production, is safe and environment-friendly, and can obtain the nano-fluid with high heat transfer coefficient, high thermal conductivity, low flow resistance and long-term stable dispersion.

Owner:ENN GRAPHENE TECH CO LTD

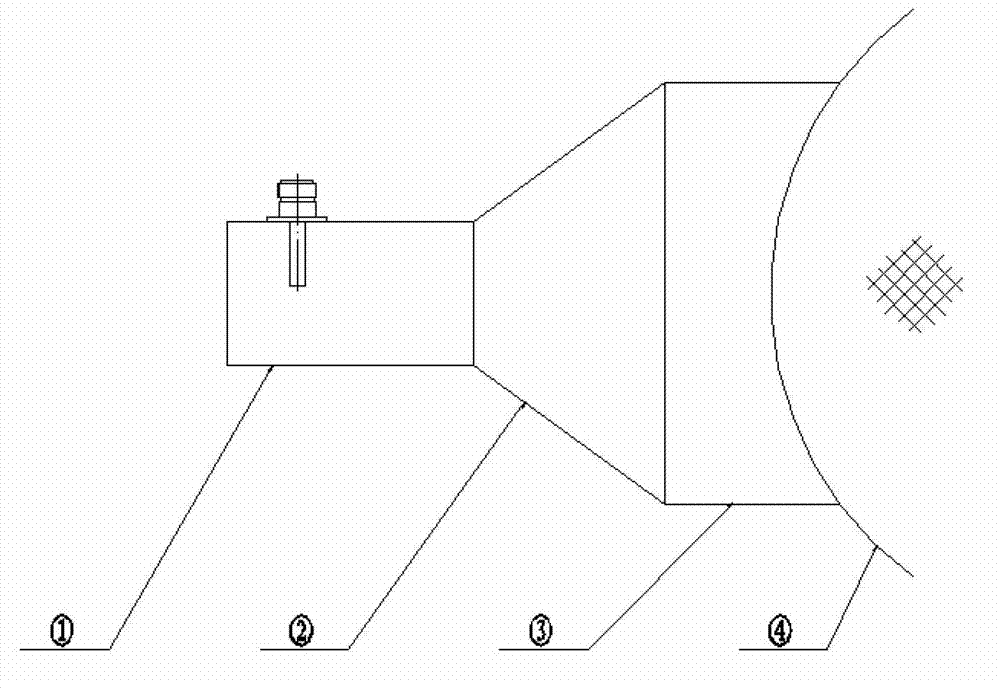

Large-caliber series self-converging tissue lens focusing radiator

InactiveCN102895739AUniform thermal field distributionGood heat transferMicrowave therapyPhysicsHorn antenna

The invention relates to a microwave radiator for microwave physical therapy of human tissues, in particular to a large-caliber series self-converging tissue lens focusing radiator and belongs to the technical field of microwave physical therapy. According to the series radiator, a pyramidal horn antenna with operating frequency of 2,450 MHz is used, and different large-caliber sizes are selected according to different application parts. The opening surface of the radiator is designed according to a lens antenna, microwaves can be converged at deep tissues by utilizing a human tissue lens which is naturally formed a high relative dielectric constant of the human tissues during clinical application, and the radiator has a certain capacity of heating the deep tissues through good heat transport and heat conduction functions of the tissues; and therefore, a clinical application range of 2,450 MHz microwave is greatly widened.

Owner:江苏诺万医疗设备有限公司

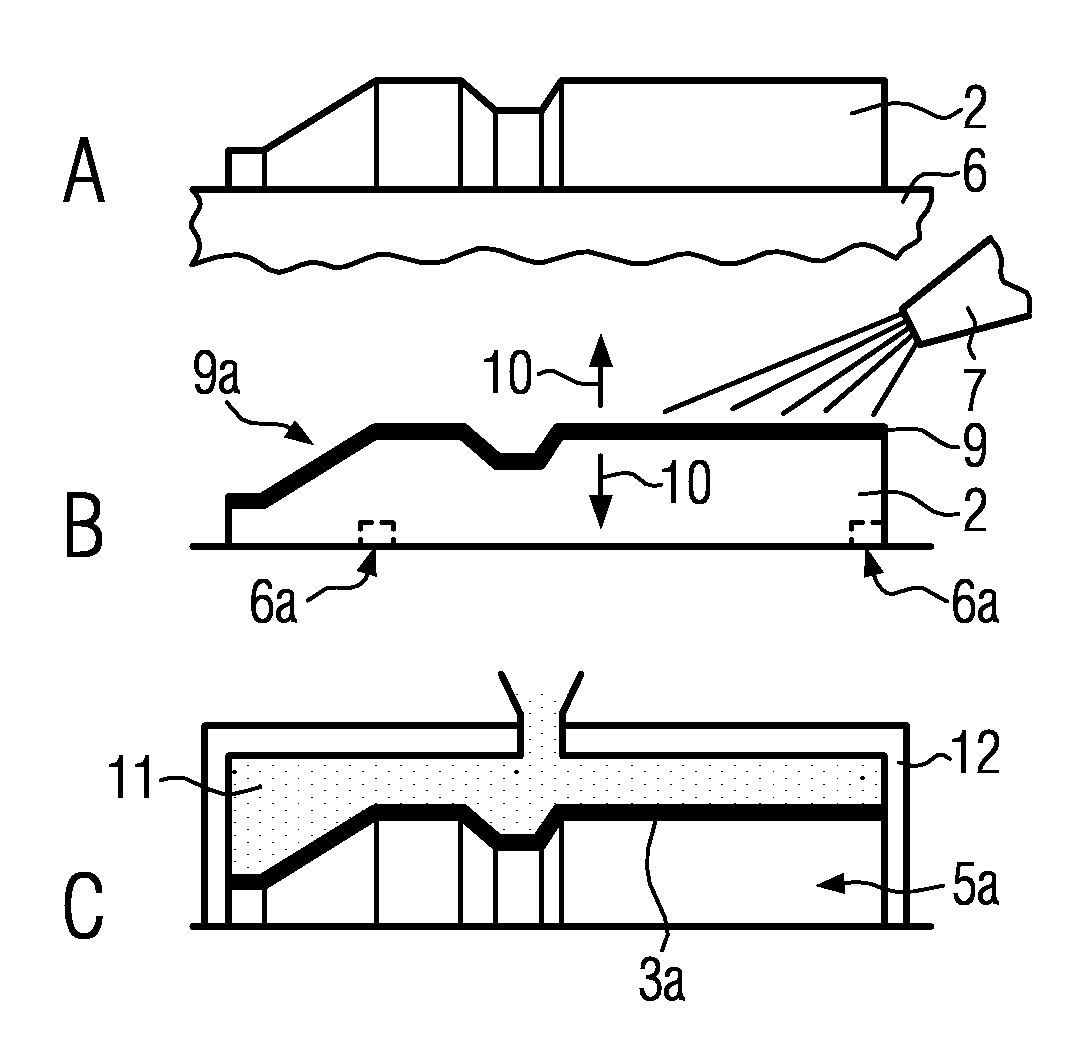

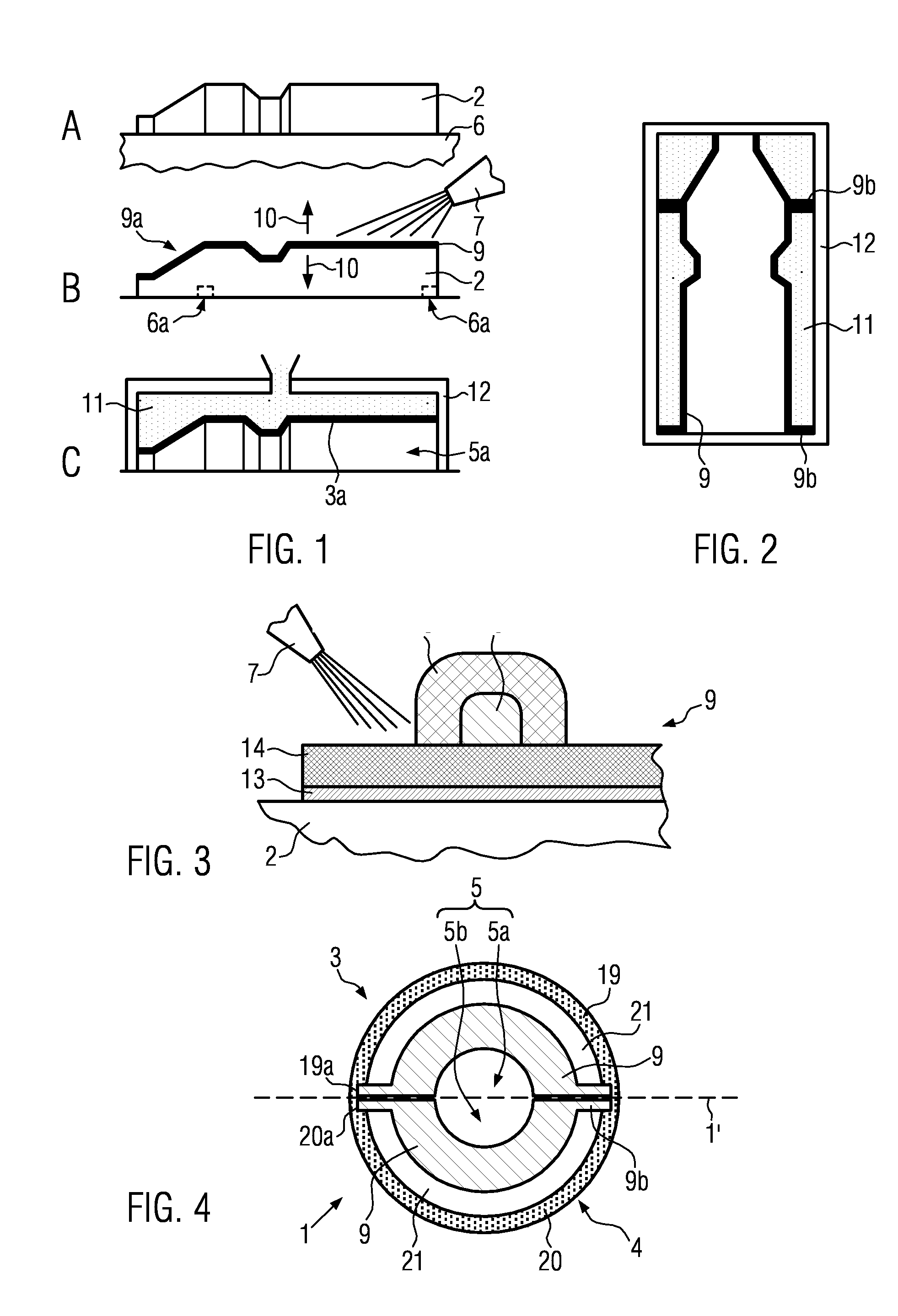

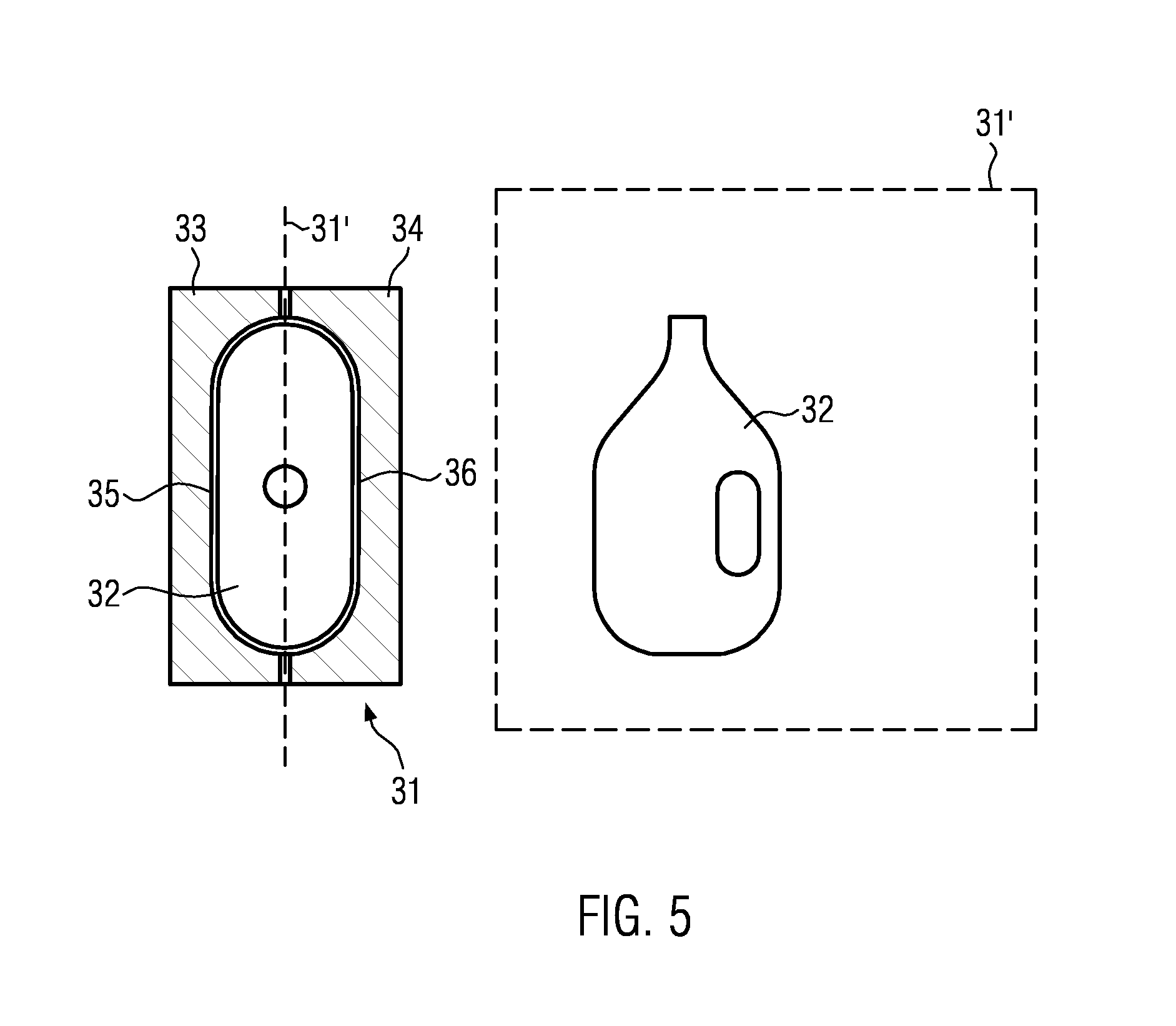

Method for manufacturing blow molds

ActiveUS20140106105A1Improve heat transferGood heat transferLiquid surface applicatorsMolten spray coatingManufacturing engineering

A method for manufacturing segmented blow molds for plastic containers, where blow mold preforms are manufactured by flame-spraying at least one metal-containing and / or ceramic-containing layer on a negative model of at least one segment of the blow mold to be manufactured, and the at least one layer is then detached from the negative model, thereby providing a particularly simple and repeatable manufacturing of blow molds.

Owner:KRONES AG

Rubber sheath material used by self-regulating electric tracing band

The invention discloses a rubber sheath material used by a self-regulating electric tracing band. The rubber sheath material comprises the following raw materials in parts by weight: 70-100 parts of ethylene propylene diene monomer, 20-50 parts of carboxylated nitrile rubber, 25-30 parts of chloroprene rubber, 1-3 parts of dicumyl peroxide, 2-6 parts of 2,5-dimethyl-2,5-di(t-butylperoxy)-3-hexyne, 1-2 parts of triallyl isocyanurate, 0.5-2 parts of sodium dichromate, 50-70 parts of modified glass fibers, 20-40 parts of graphite powder, 5-15 parts of high abrasion furnace black, 10-20 parts of silicon carbide, 8-16 parts of kaolin, 20-35 parts of copper powder, 1-2 parts of antioxidant AT-215, 2-6 parts of sodium lignosulphonate, 1-2 parts of diisodecyl phthalate, 1-2 parts of polyvinyl butyral, 1-2 parts of liquid coumarone resin and 0.8-1.5 parts of tributyl citrate. The rubber sheath material has good heat transfer performance, high hardness and excellent abrasion resistance.

Owner:崇夕山

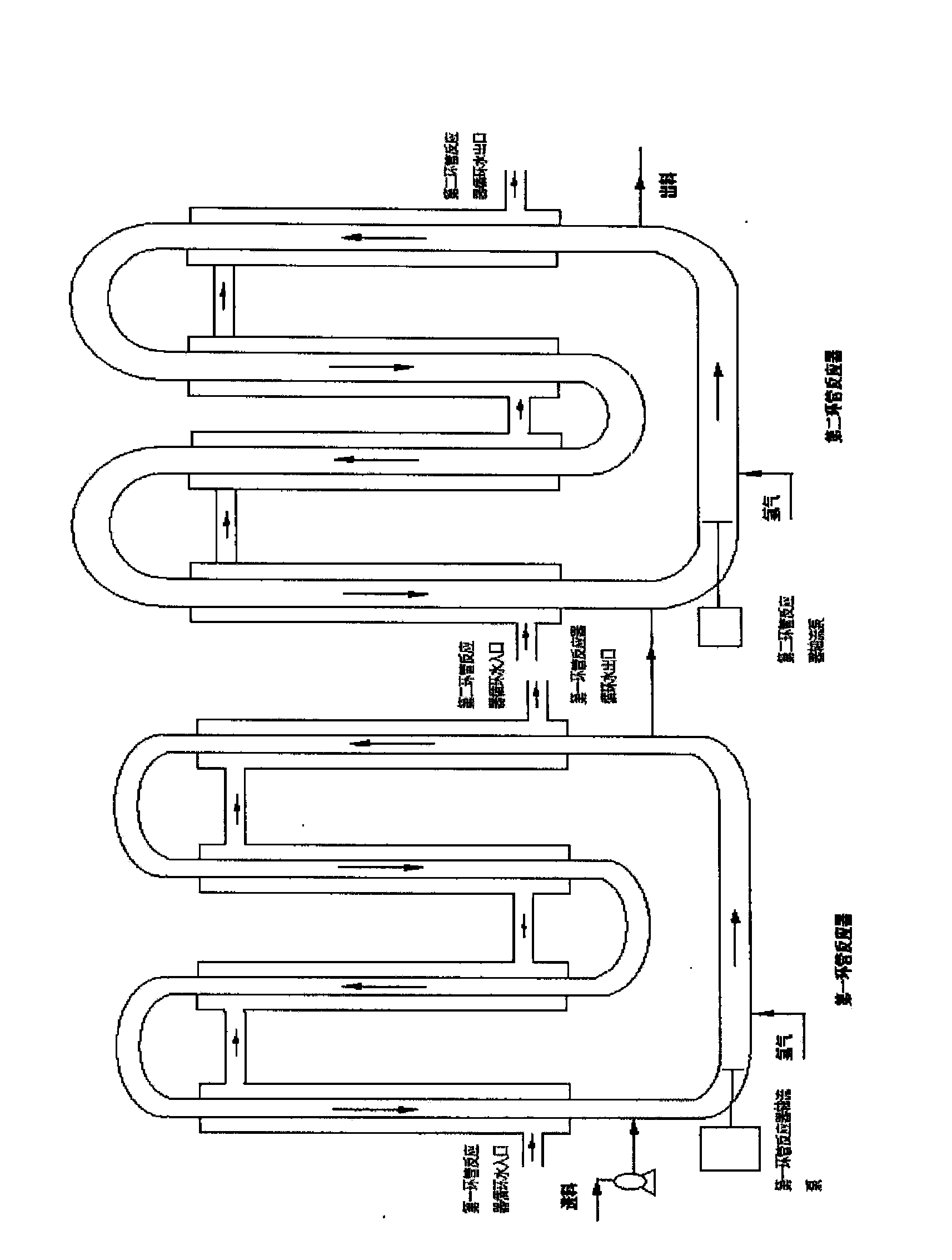

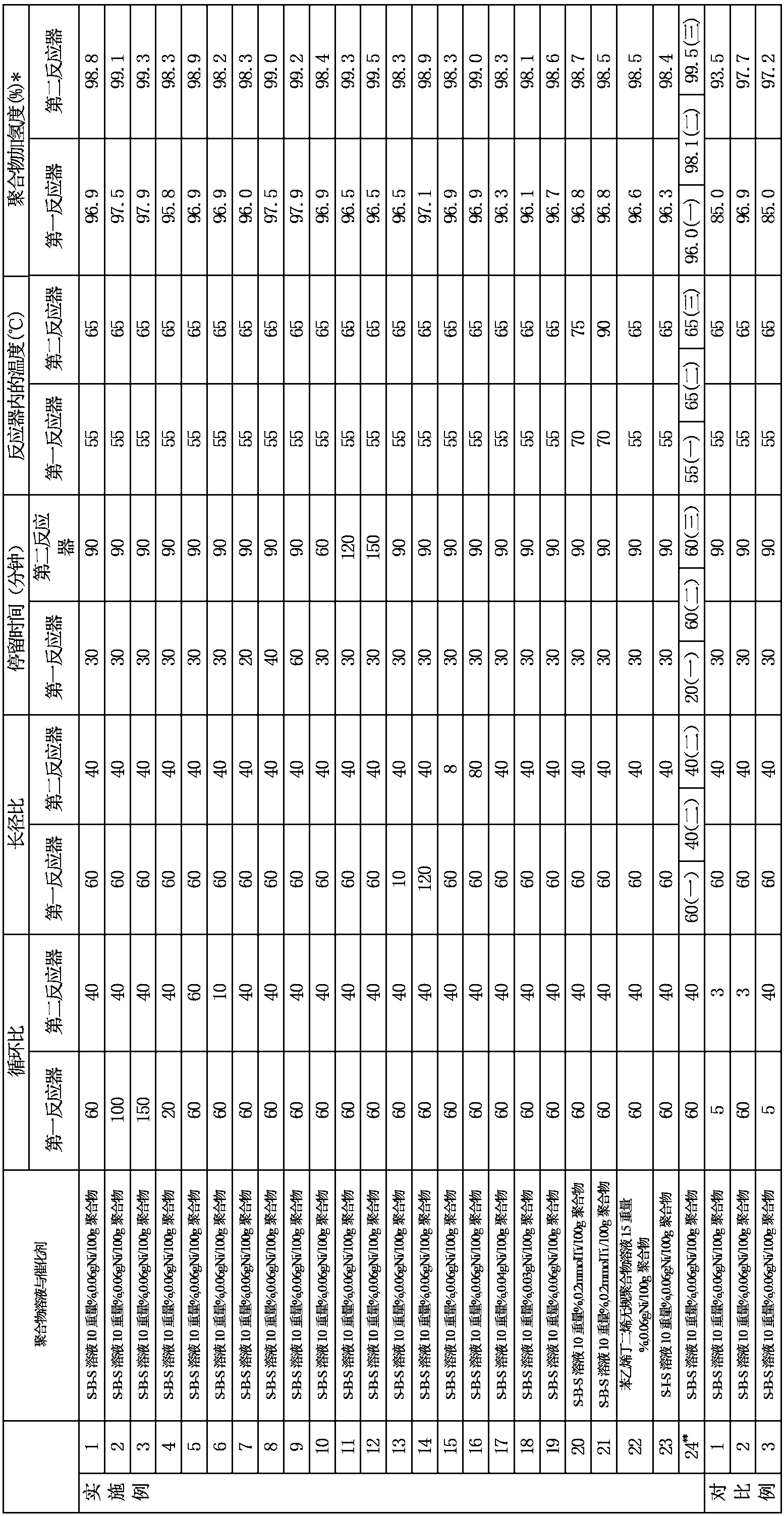

Olefines unsaturated bond-containing polymer hydrogenation reaction method

ActiveCN103788317AGood heat transferImprove hydrogenation reaction efficiencyChemistryUnsaturated bonds

The invention discloses an olefines unsaturated bond-containing polymer hydrogenation reaction method. The method comprises the following steps: under a hydrogenation reaction condition and existence of a hydrogenation catalyst, an olefines unsaturated bond-containing polymer solution and hydrogen are contacted in a reactor, wherein the reactors are two or more loop reactors connected in series, the cycle ratio of the loop reactors can be controlled so that the material in the reactor is close to a complete mixing flow state, wherein the cycle ratio of a first reactor is 10-200, and the cycle ratio of a second reactor and other reactor is 10-100. The method can better control the reaction temperature, the catalyst activity can be kept in a long operation period, hydrogenation efficiency is increased, and ideal hydrogenation degree can reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

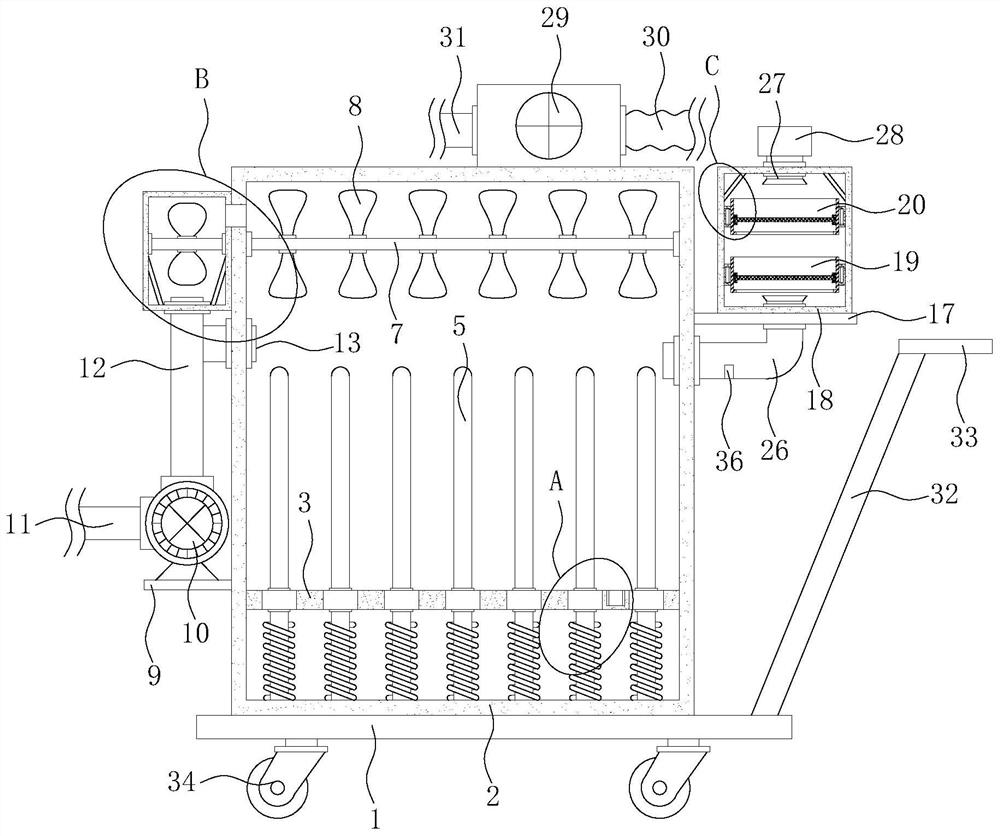

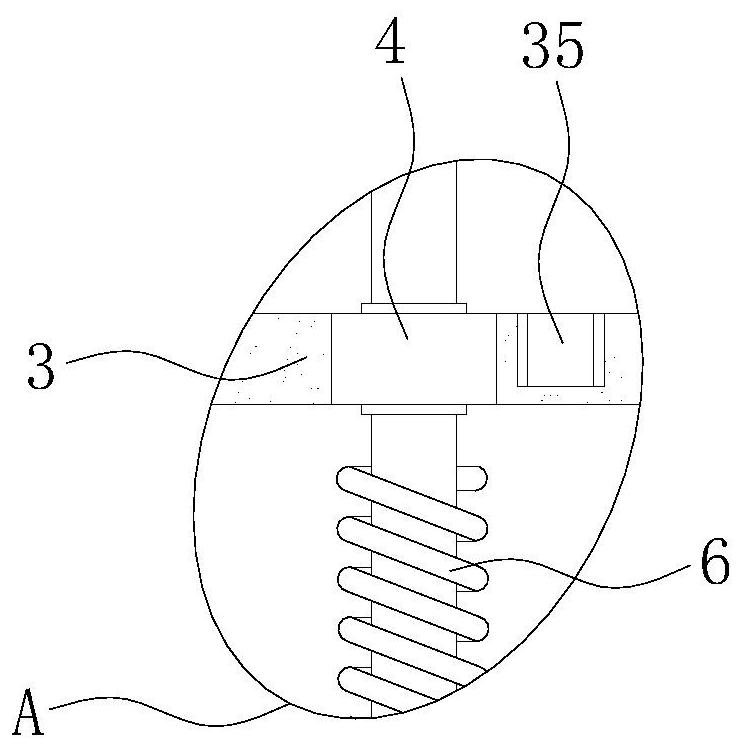

Electromagnetic superconducting drying oven

PendingCN112524935AImprove thermal effect utilizationFast heat absorptionDrying gas arrangementsAir heatersEngineeringMechanical engineering

The invention discloses an electromagnetic superconducting drying oven, and relates to the technical field of drying ovens. The electromagnetic superconducting drying oven comprises an installation plate, a drying oven body is welded to the outer surface of the top of the installation plate, a partition plate is welded to the interior of the drying oven body and divides the drying oven body into an upper cavity and a lower cavity, an opening is formed in the partition plate, a sealing block is fixedly installed in the opening, and a vacuum superconducting pipe is fixedly installed at the bottom of the drying oven body. On one hand, hot air generated by the vacuum superconducting pipe can be conveyed to needed materials, on the other hand, adsorption force during air suction can serve as apower source, and air in the vacuum superconducting pipe can be stirred conveniently, so that the liquidity of the hot air in the drying oven is effectively guaranteed, the situation that part of local heat of the vacuum superconducting pipe cannot be fully adsorbed and utilized due to direct adsorption is avoided, and the energy-saving efficiency of the drying oven is further guaranteed, and in addition, the cost of the mechanism is low, and the heat effect utilization rate can be fully increased again.

Owner:山东锦恒环保设备有限公司

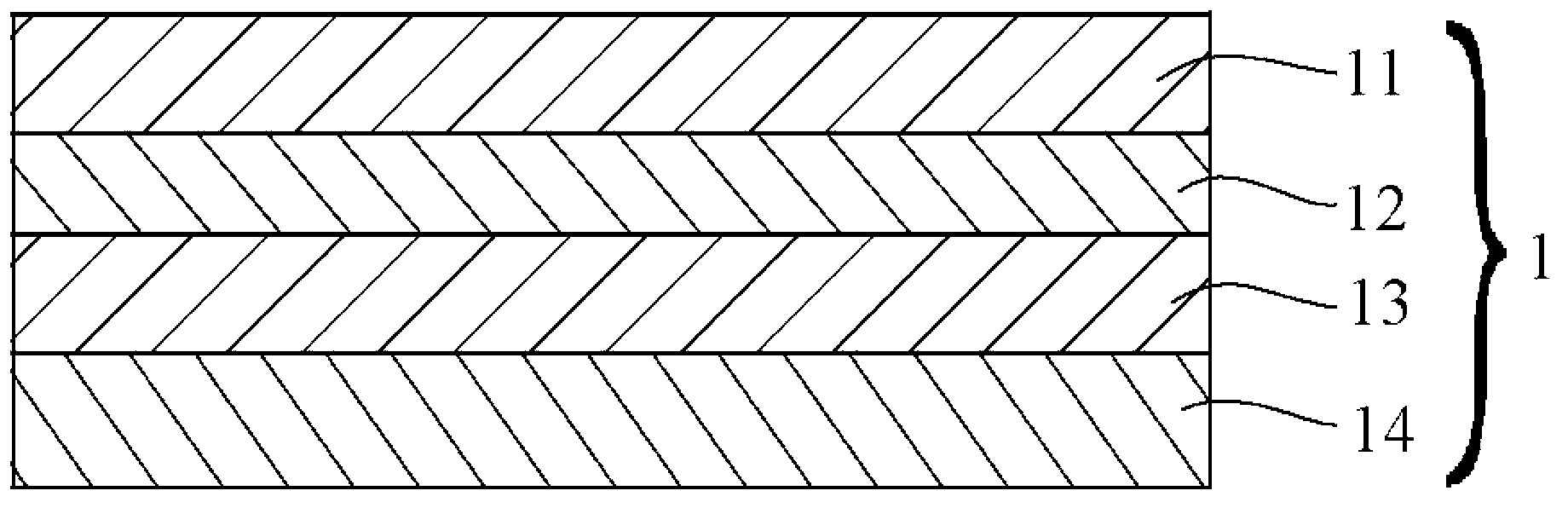

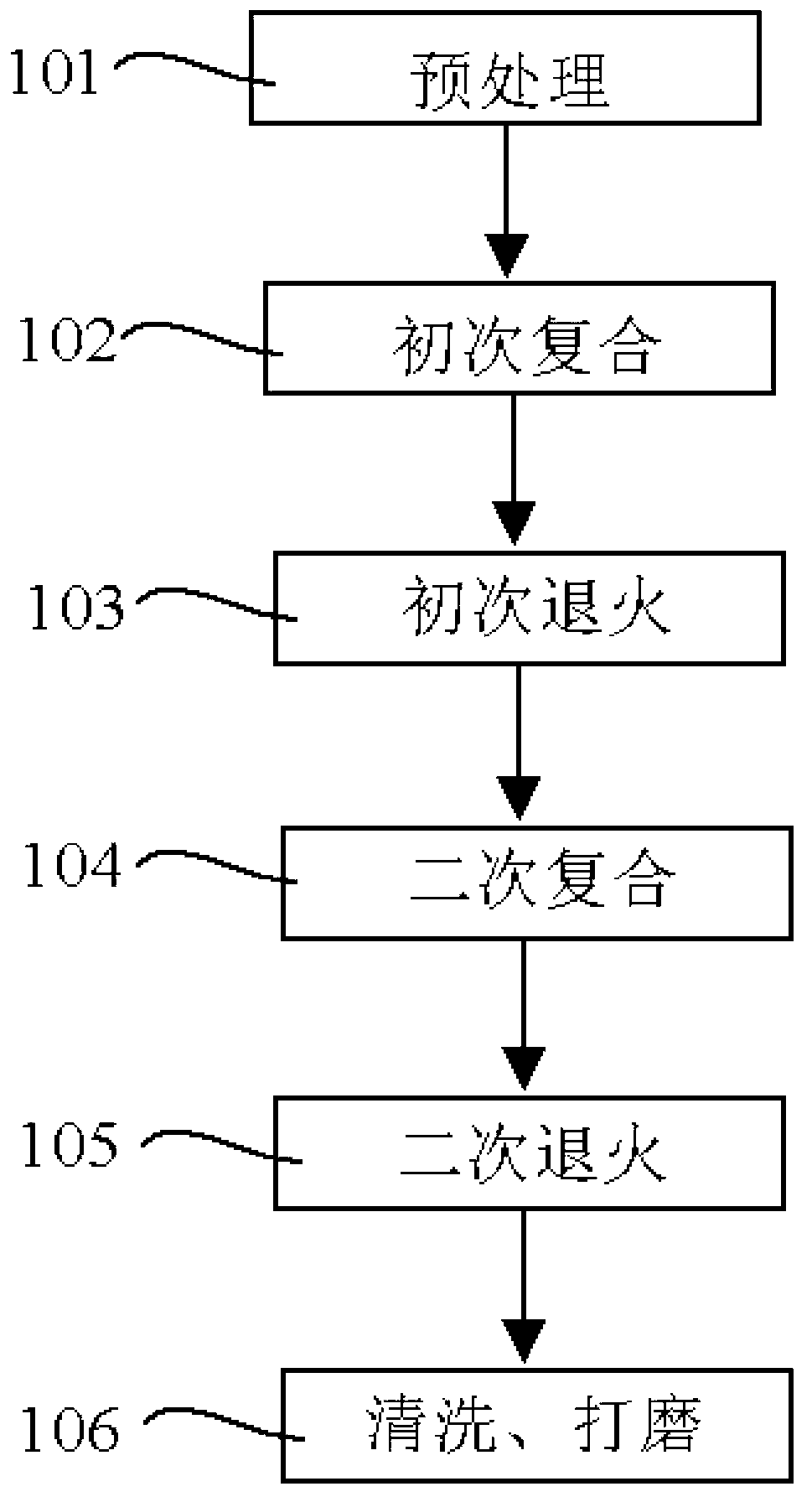

Multi-layer cooking appliance containing magnalium and preparation method of composite board of multi-layer cooking appliance

InactiveCN103300741ALight in massGood heat transferCooking-vessel materialsLaminationDeep drawingMagnalium

The invention relates to a multi-layer cooking appliance containing magnalium, which comprises a cooking appliance body and a handle arranged on the cooking appliance body, wherein the cooking appliance body is formed by sequentially stamping a plurality of metal composite boards, namely a 304 stainless steel layer with the thickness of 0.5-2mm, a magnalium layer with the thickness of 0.5-2mm, a pure aluminum layer with the thickness of 0.5-2mm, and a 430 stainless steel layer with the thickness of 0.5-2mm from inside to outside. The multi-layer cooking appliance has the benefits that the composite board can adapt to various cold processing such as deep drawing, stretching, bulging, bending, punching and hauling, without layering, so that the cooking appliance can still keep the original firm bonding state; and the cooking appliance is light in mass and rapid in heat transfer, has good heat transfer property, saves energy, and is suitable for various different cooking ranges.

Owner:上海乾天厨房用具有限公司

Electric Heating Device

PendingUS20210037615A1Improve thermal conductivityGood heat transferFluid heatersHeater elementsPhysicsElectrically conductive

An electric heating device includes a housing having a partition wall which separates a connection chamber from a heating chamber for dissipating heat and from which at least one receiving pocket, protruding into the heating chamber as a heating rib tapering towards its lower, closed end protrudes. A PTC heating element includes at least one PTC element and conductor tracks for energizing the PTC element with different polarities. The conductor tracks are electrically conductively connected to the PTC element and are electrically connected in the connection chamber. A pressure element is received which holds heat extraction surfaces of the PTC element abutted against oppositely disposed inner surfaces of the receiving pocket. The pressure element includes a sheet metal strip which, by punching and bending, forms spring segments protruding from the plane of the sheet metal strip. The spring elements are provided in a planar manner distributed over a heat extraction surface of the PTC element provided adjoining the respective pressure element.

Owner:EBERSPACHER CATEM

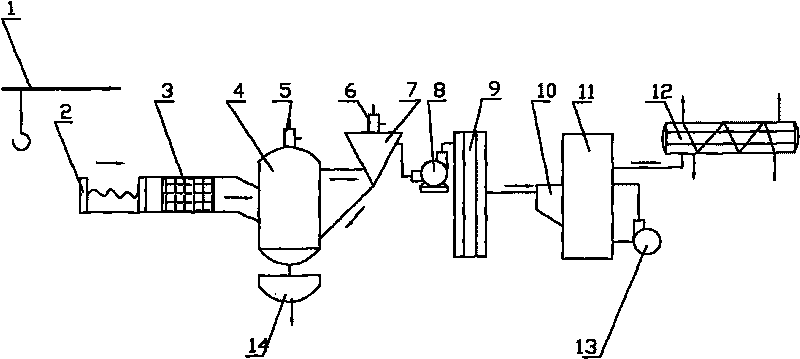

Device and method for processing active carbon containing heavy metals and fine dust

ActiveCN101745517AGood heat transferImprove efficiencyWaste processingSolid waste disposalQuenchingActive carbon

The invention relates to a device and a method for processing active carbon containing heavy metals and fine dust. The device comprises a feeding device, a plasma furnace, a waste heat recovery device, a sharp quenching device, a desulphurization and dust removal tower and a condensing device, wherein the desulphurization and dust removal tower comprises a seriflux storage section, a flue gas stabilizing section, a filtering section and a defogger; the filtering section of the desulphurization and dust removal tower comprises a plurality of filtering units; and the inlet of the filtering unit is in the shape of a circular cylinder, an outlet is in the shape of a horn, the diameter phi 1 is 80 to 500mm, the diameter phi 2 is 200 to 900 mm, the divergence angle alpha is 4 to 9 degrees, the length L1 is 100 to 450 mm, and the length L2 is 600 to 2500 mm. The invention adopts the remolded desulphurization and dust removal tower, and is characterized by depriving the fine dust and heavy metals in the desulphurization at the same time, wherein the removal rate of dust with the size of 1 to 5 mum can reach more than 90%; and the removal rate of divalent mercury can reach more than 85%.

Owner:HEBEI AEROSPACE ENVIRONMENTAL ENG CO LTD

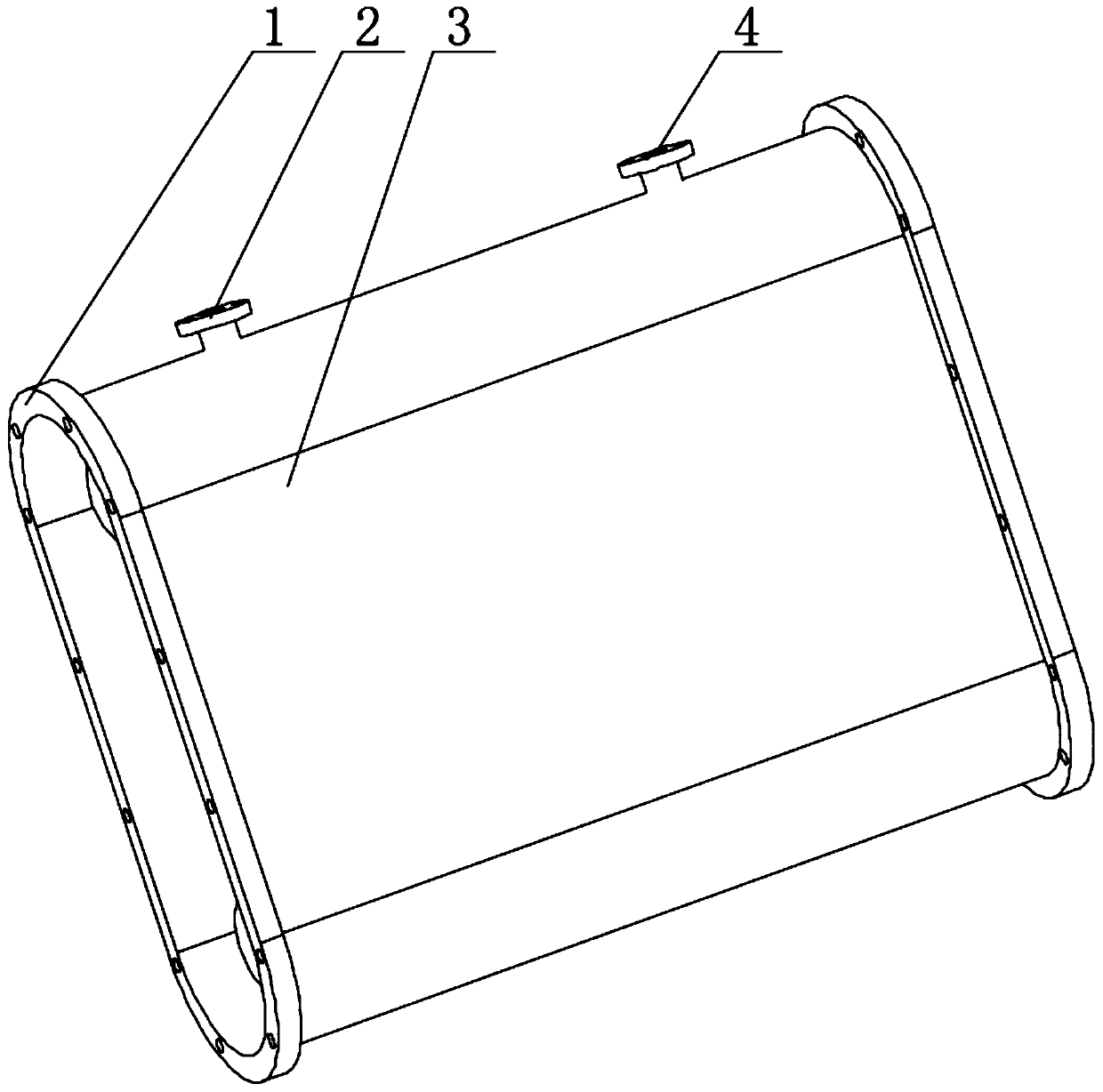

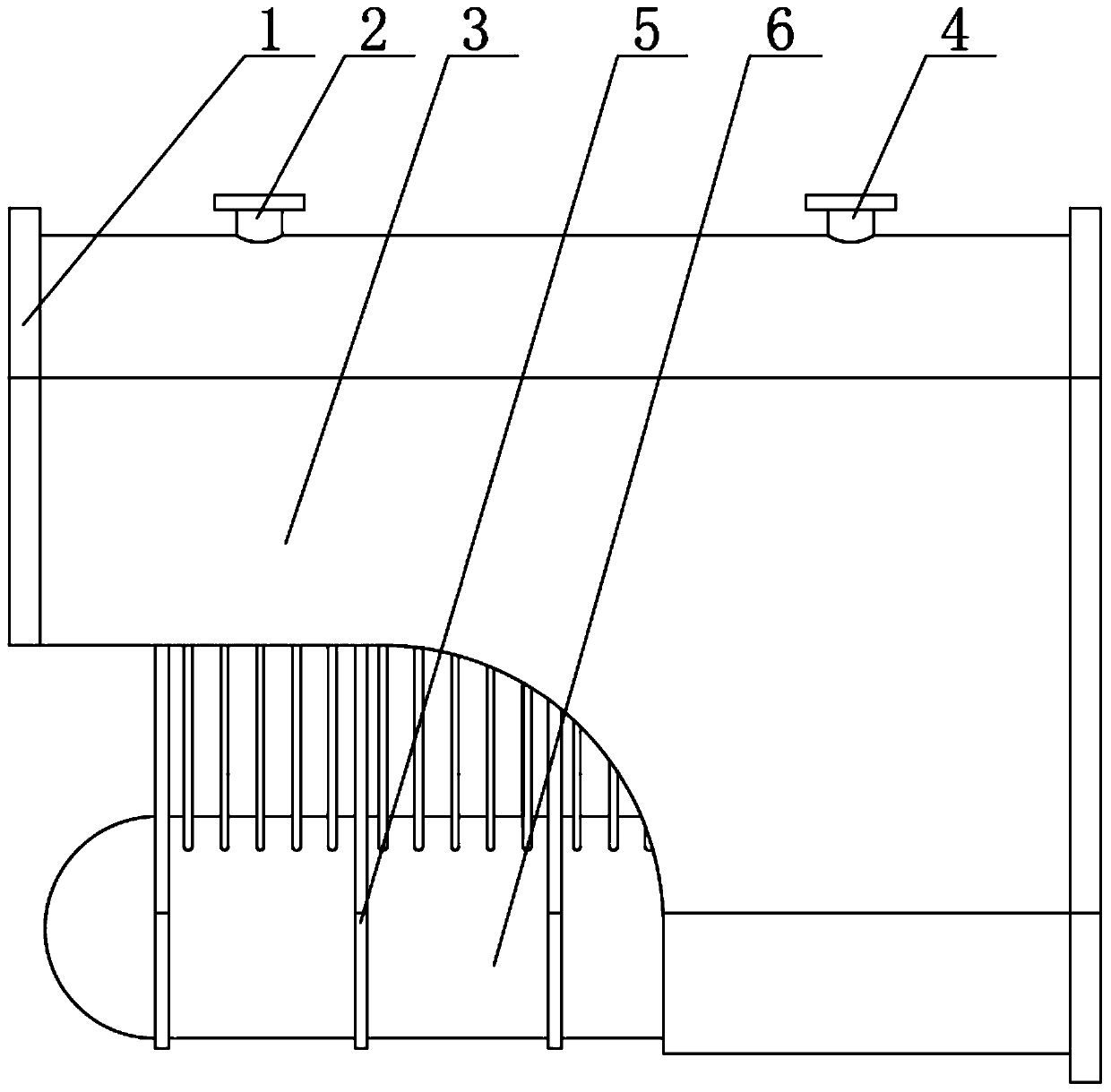

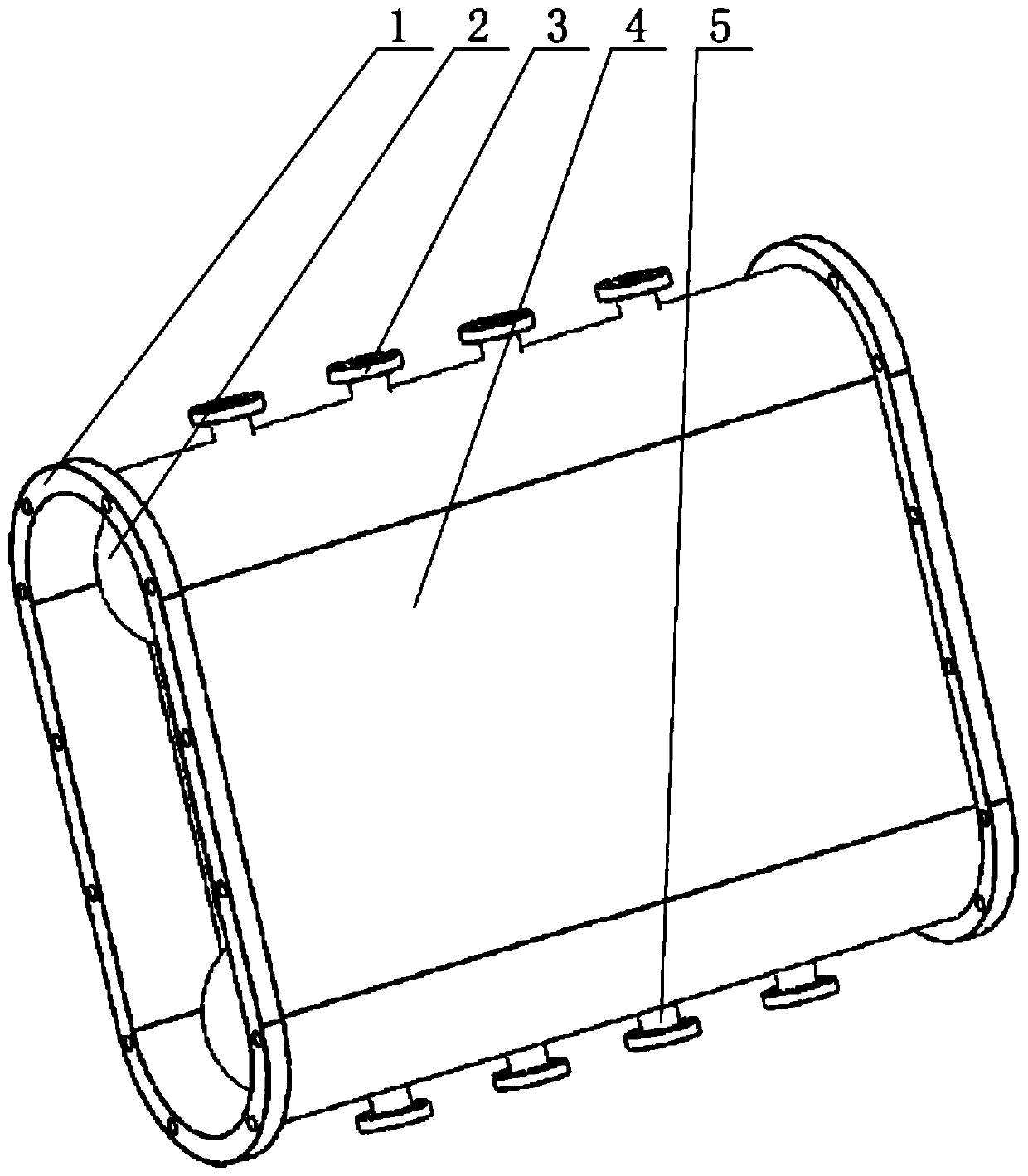

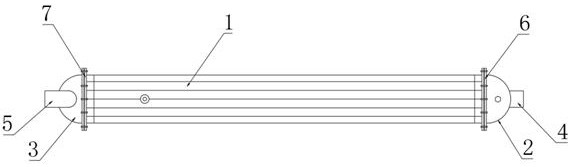

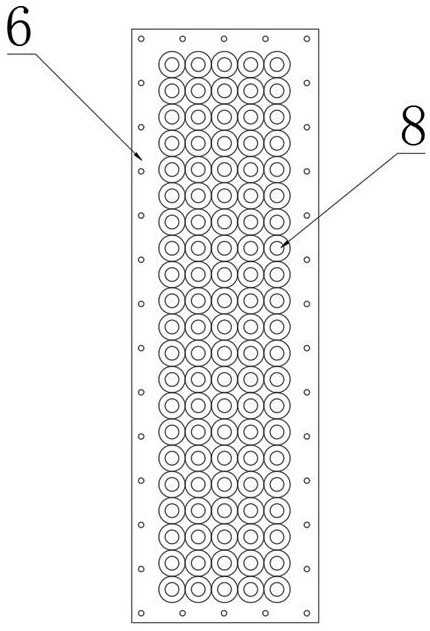

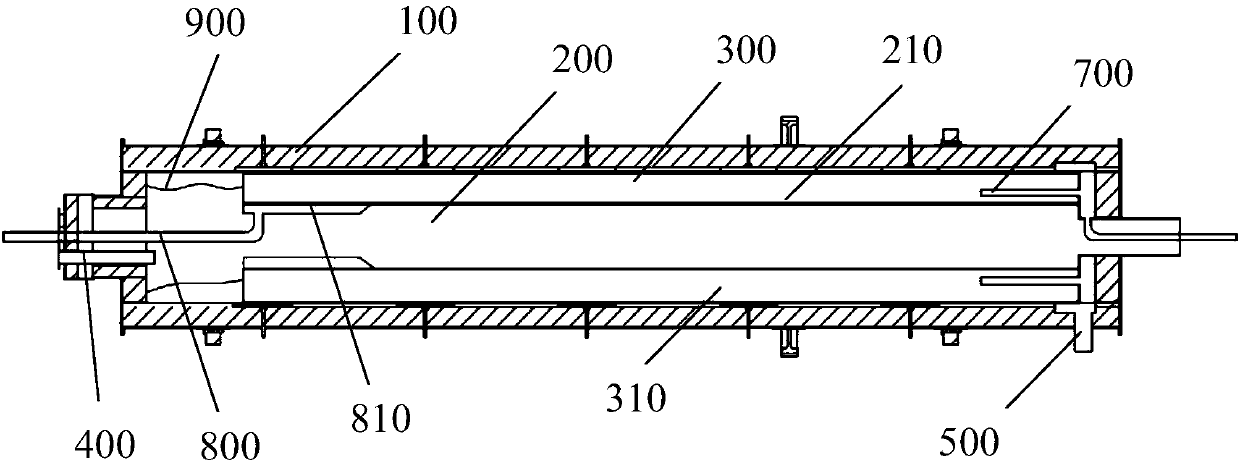

An inboard heat exchanger suitable for underwater equipment

ActiveCN110207507BAvoid troublesome operationCompact structureStationary conduit assembliesHeat exchanger casingsEngineeringFresh water

The invention relates to an inter-board heat exchanger suitable for underwater equipment. The inter-board heat exchanger suitable for the underwater equipment comprises a shell pass shell; the sectionof the shell pass shell is of an elliptic structure; end covers are mounted at the two ends of the shell pass shell; the structures of the end covers are matched with the section of the shell pass shell in shape; a fresh water inlet connecting pipe and a fresh water outlet connecting pipe are arranged at the top of the shell pass shell at intervals; a pipe box cylinders are arranged in the shellpass shell up and down at intervals; single pipe box cylinders are transversely arranged; two pipe box cylinders are fixedly connected through multiple spaced frames; the frames are connected with theinner wall surface of the shell pass shell; and two pipe box cylinders communicate through heat exchange pipe bundles. The inter-board heat exchanger suitable for the underwater equipment is directlyplaced in seawater, and is compact in structure and high in heat exchange efficiency.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

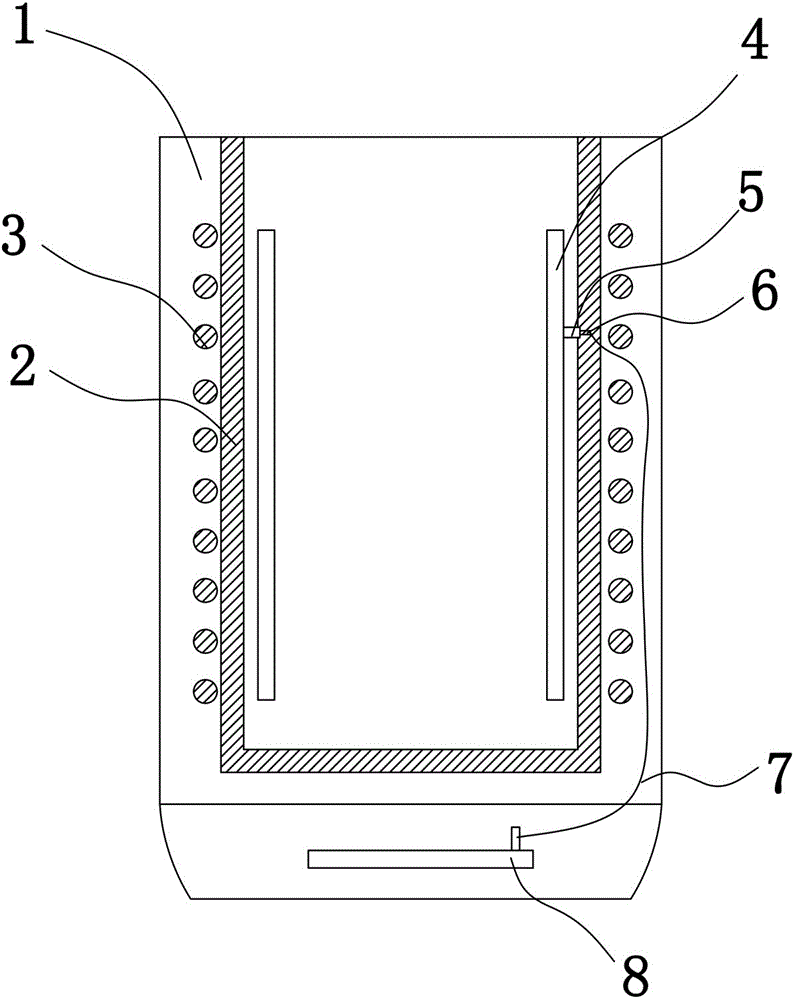

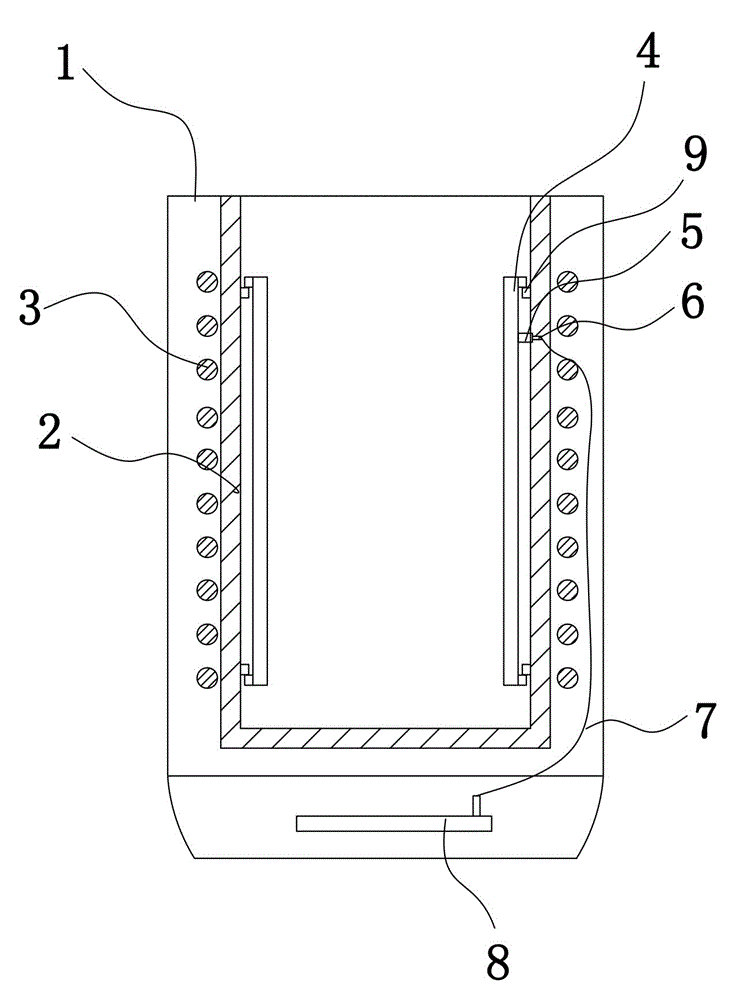

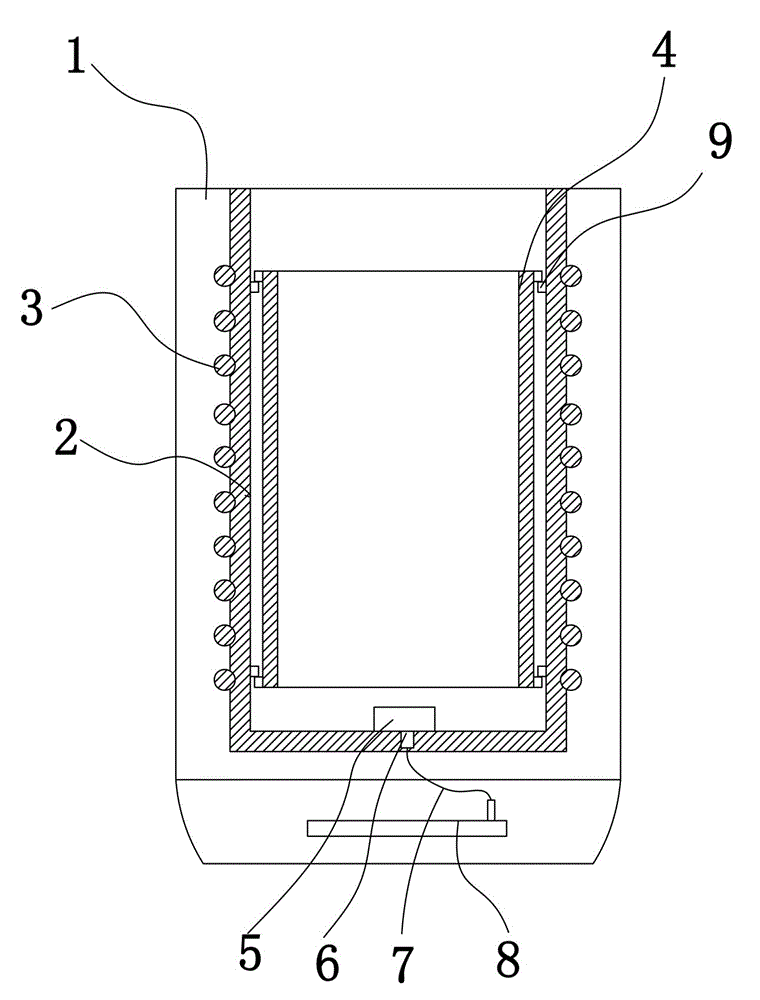

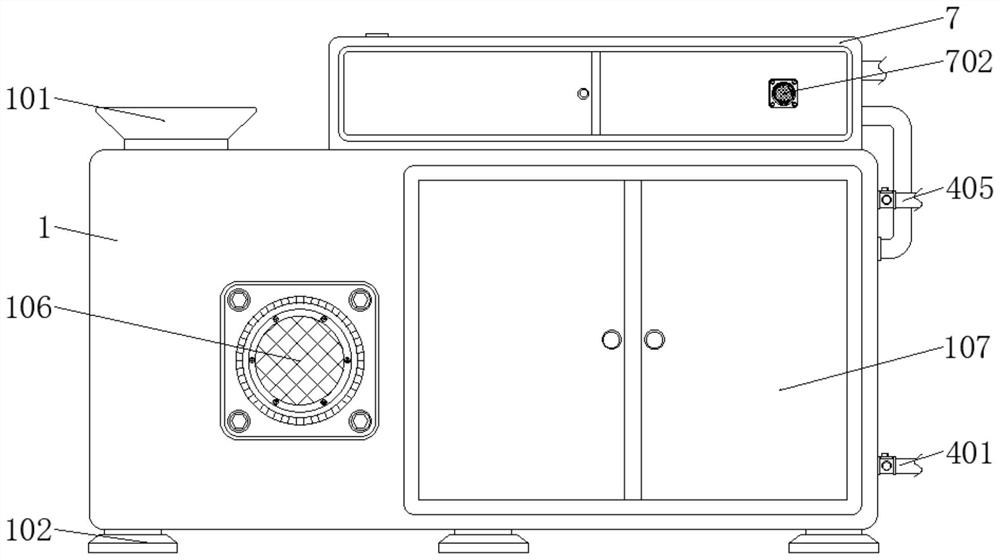

Cabinet

ActiveCN104602469AGood heat transferGood sealingCasings/cabinets/drawers detailsModifications for standard racks/cabinetsNarrow rangeHeat conducting

The invention provides a cabinet. The cabinet is provided with an inner wall and an outer wall, wherein the inner wall and the outer wall form a cavity. The cabinet is further provided with a heat conducting plate, wherein the heat conducting plate is arranged between the inner wall and the outer wall, the cavity is divided into an inner cavity and an outer cavity which are isolated mutually, the inner cavity is mutually communicated with the inside of the cabinet so as to form internally circulating air flows, and the outer cavity is mutually communicated with the outside of the cabinet so as to form externally circulating air flows. The cabinet is further provided with turbulent flow fins, wherein the turbulent flow fins are arranged in the inner cavity or / and the outer cavity and used for changing the internally circulating air flows or / and externally circulating air flows into eddy flows. The cabinet is provided with the heat conducting plate and the turbulent flow fins, so that the heat exchange capacity of the heat conducting plate is remarkably improved under the condition that flowing resistance of the air flows is only increased within a narrow range, the heat dissipation efficiency of the whole cabinet is improved, and sealing performance of the cabinet is ensured.

Owner:HUAWEI TECH CO LTD

Chondroitin sulfate sodium salt heat energy circulating device

InactiveCN111701279APlay the function of preheatingGood heat transferRecuperative heat exchangersSolid sorbent liquid separationSludgeHeat conservation

The invention provides a chondroitin sulfate sodium salt heat energy circulating device, which comprises a resin adsorption device, a first connecting pipe, a first valve, a waste liquid tank, a second connecting pipe, a second valve, a storage tank, a third connecting pipe, a third valve, a multi-stage filter, a filter screen, a fourth connecting pipe, a fourth valve, a water suction pump, a heatexchange pipe, a fifth connecting pipe, a heat preservation tank, a temperature control heating pipe, a water outlet pipe, a fifth valve, a heat preservation preheating sleeving shell structure, a movable pushing plate frame structure, an auxiliary driving wheel structure, a sealable discharging pipeline structure, a PLC and a driving switch, wherein one end of the first connecting pipe is connected with a left flange at the lower end of the resin adsorption device, and the other end of the first connecting pipe is connected with an upper flange of the waste liquid tank. The device has the beneficial effects that through the arrangement of the movable pushing plate frame structure, when a movable screw rod moves, a dredging plate is better driven to move, impurities such as sludge in a multistage filter are cleaned, and then the cleaning effect is improved.

Owner:山东冰文生物技术有限公司

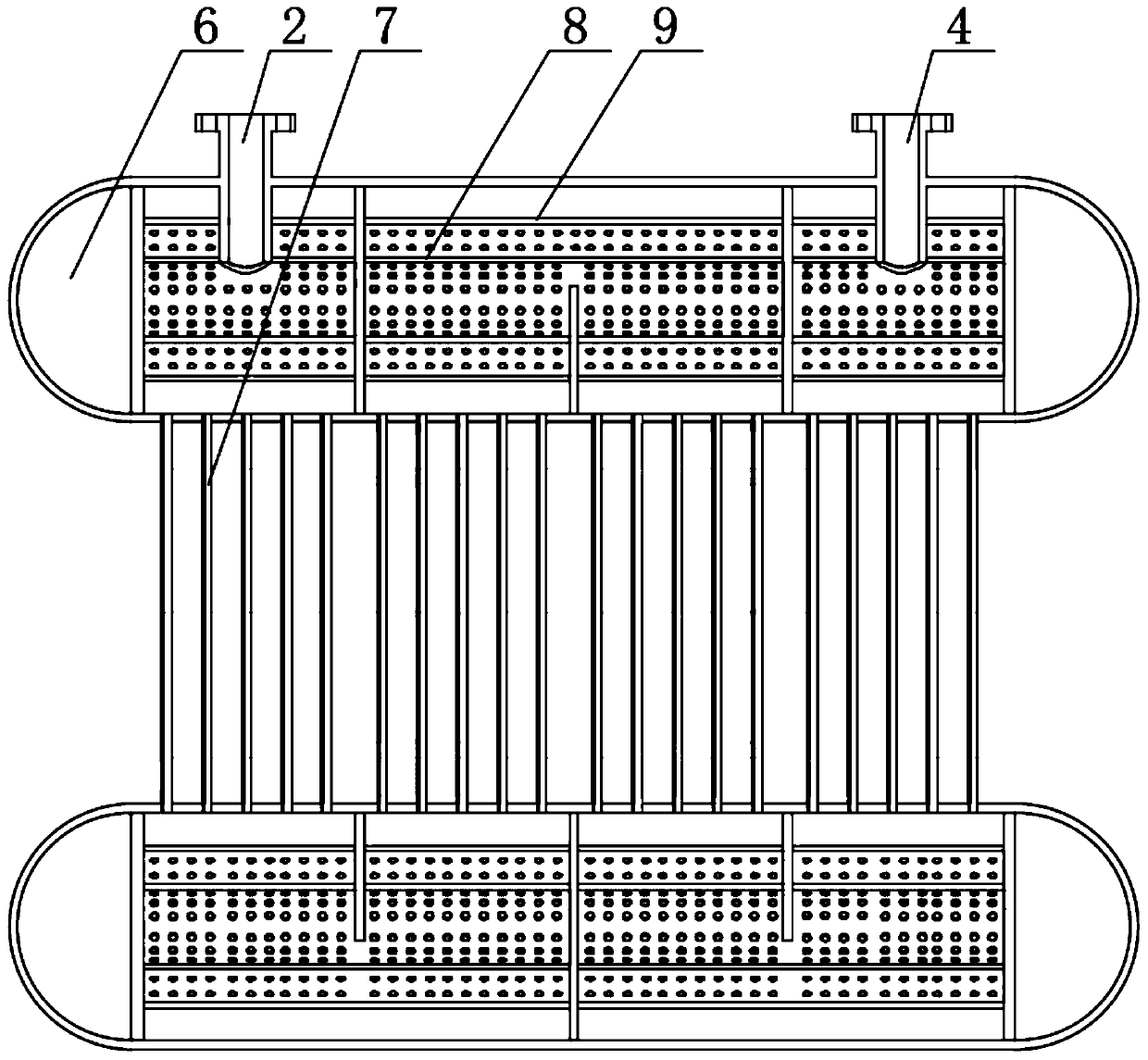

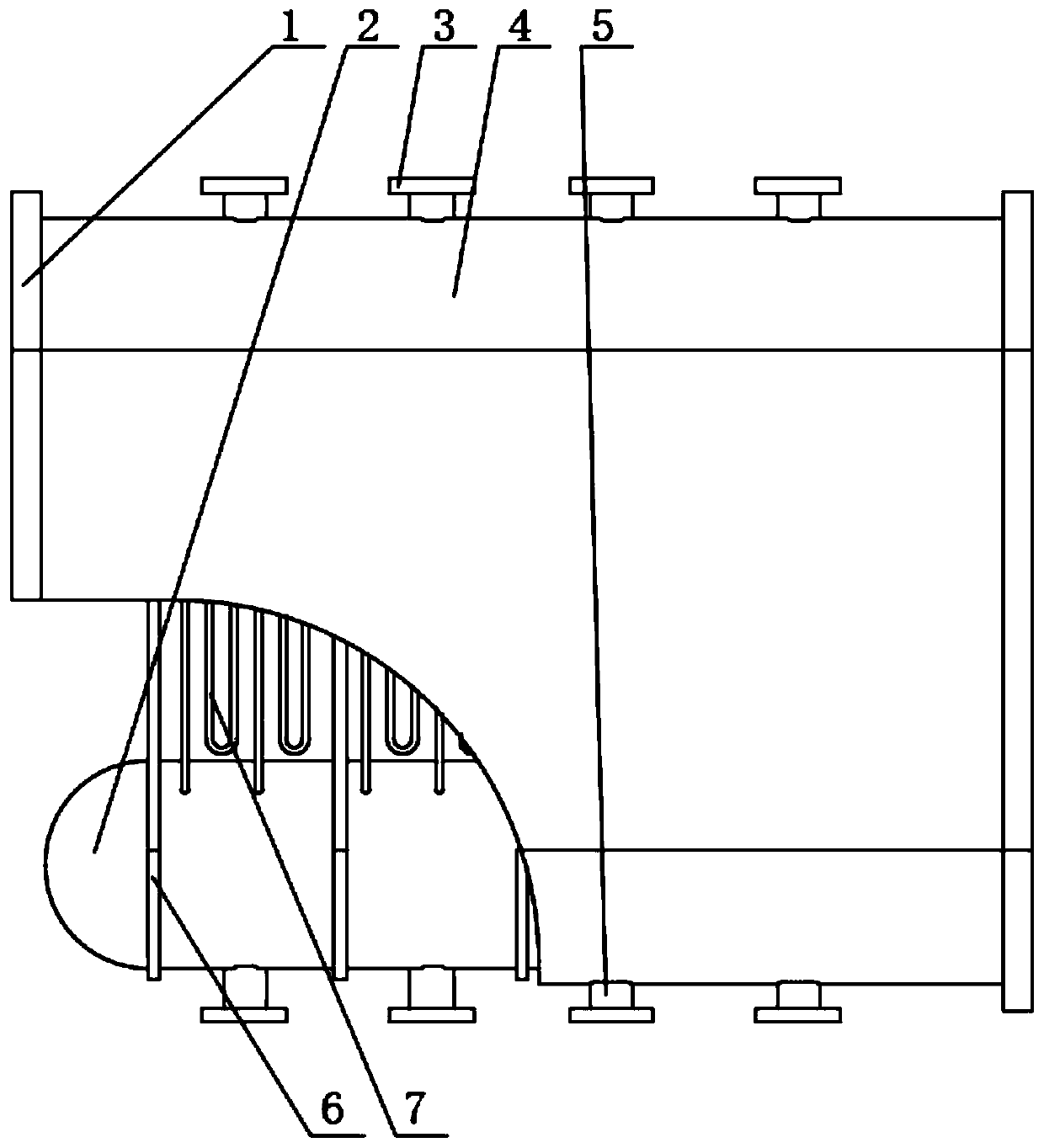

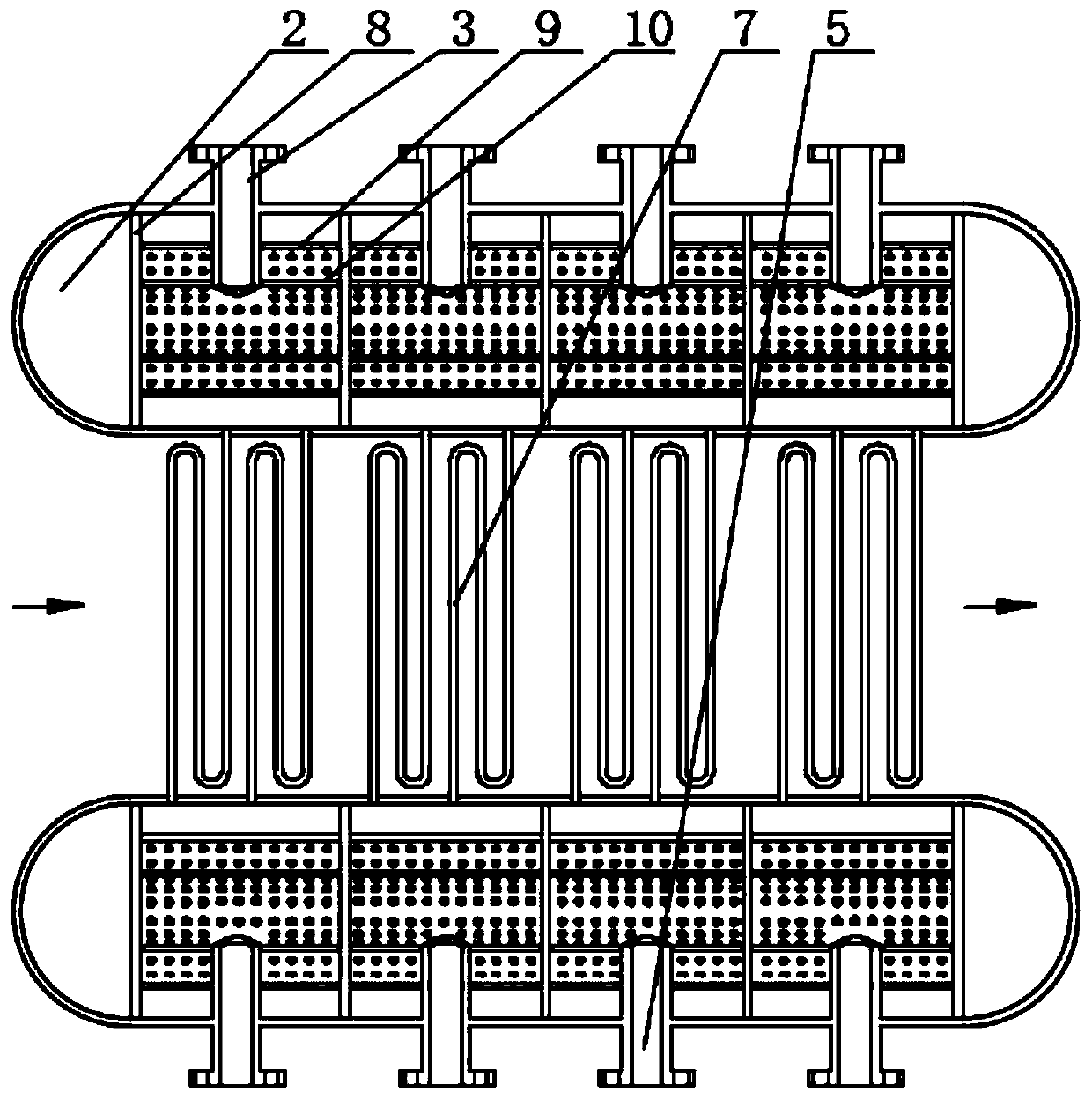

Heat exchanger suitable for multi-pressure-resistant shell underwater equipment and using method of heat exchanger

ActiveCN110207506ACompact structureEasy to operateStationary conduit assembliesHeat exchanger casingsSeawaterEngineering

The invention relates to a heat exchanger suitable for multi-pressure-resistant shell underwater equipment and a using method of the heat exchanger. The heat exchanger suitable for the multi-pressure-resistant shell underwater equipment comprises pipe box cylinders which are arranged in parallel in an up-and-down interval manner; the two pipe box cylinders are transversely arranged; the two pipe box cylinders are supported and installed through a plurality of frames; the two tube box cylinders communicate with each other through a heat exchange tube bundle; a shell which penetrates left and right is surrounded outside the frames; the left end and the right end of the shell are open; end covers are arranged at the openings; a plurality of fresh water outlets are formed in the top surface ofthe shell; and a plurality of fresh water inlets corresponding to the fresh water outlets are formed in the bottom surface of the shell. The heat exchanger can be directly placed in seawater, the heat exchange work is achieved conveniently, through the large-caliber seawater inlets and the large-caliber seawater outlets can be conveniently realized, the trouble that seawater is conveyed into a heat exchanger in a cabin from a sea water pump in the prior art is avoided, and the heat exchanger is convenient and rapid to install and high in heat exchange efficiency.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Reflow furnace smoke removing method

InactiveCN108723539AGood heat transferAvoid overheatingPrinted circuit assemblingWelding/cutting auxillary devicesSolder pasteEngineering

The invention discloses a reflow furnace smoke removing method and relates to the technical field of electronic equipment soldering. The reflow furnace smoke removing method comprises the steps that S1, the surface of a printed circuit board to be soldered is coated with soldering paste, the soldering paste coating printed circuit board is put into a reflow furnace, the printed circuit board put into the reflow furnace enters a preheating area, water in the soldering paste is evaporated, soldering flux is used for wetting a component pin and a bonding pad, and the soldering paste begins to soften and cover the bonding pad so that the component pin and the bonding pad are isolated from the oxygen; and S2, then the printed circuit board enters a reflow area. According to the reflow furnace smoke removing method, the smoke removing effect is greatly enhanced, smoke solidified crystals are prevented from depositing on fan blades, great centralized cooling and filtering treatment is carriedout on reflow gas with soldering flux smoke in the reflow furnace, the purpose of guaranteeing that the printed circuit board carries out soldering work well is achieved well, and therefore a manufacturing enterprise of the printed circuit board is completely facilitated.

Owner:武汉倍普科技有限公司

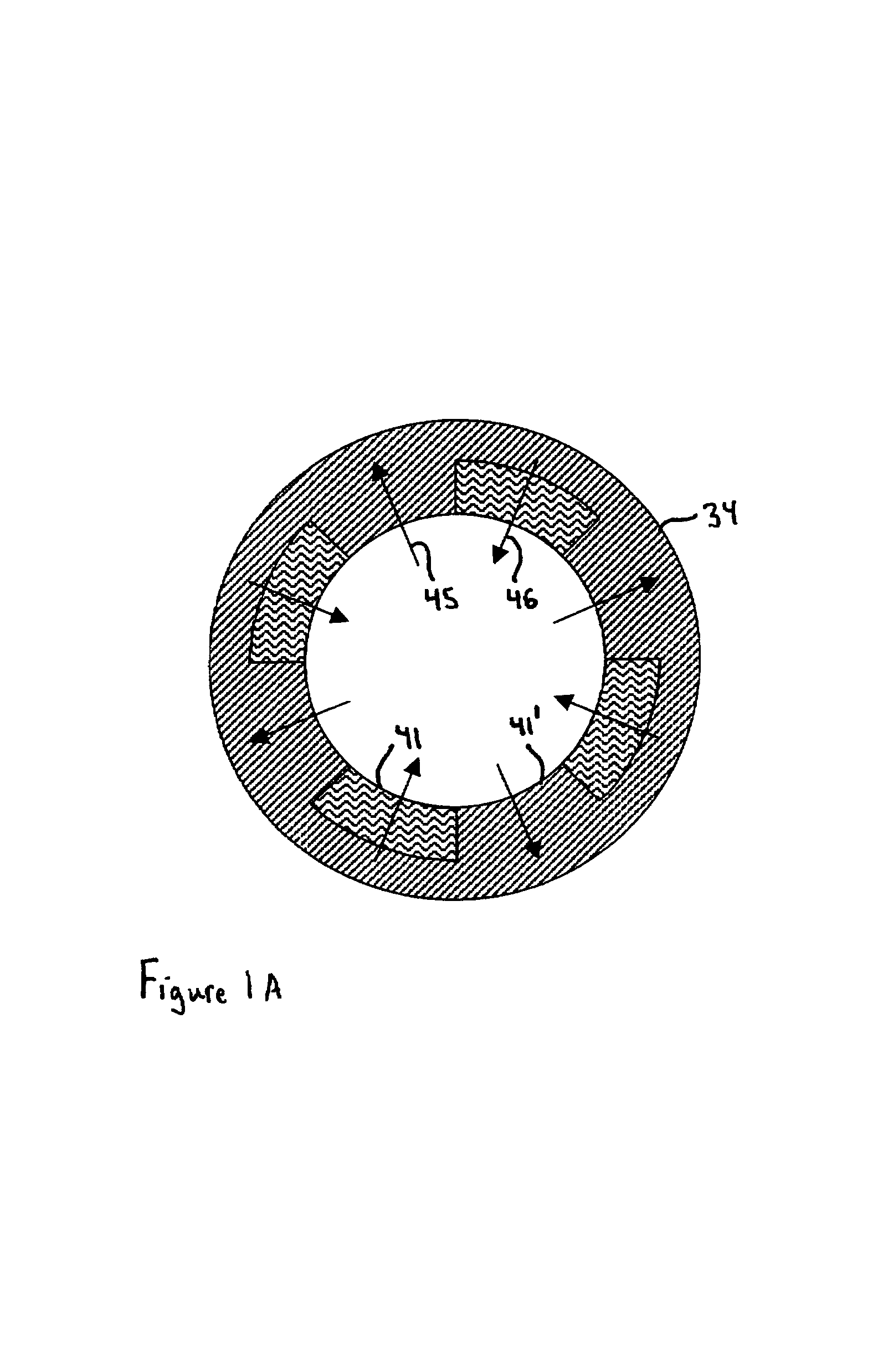

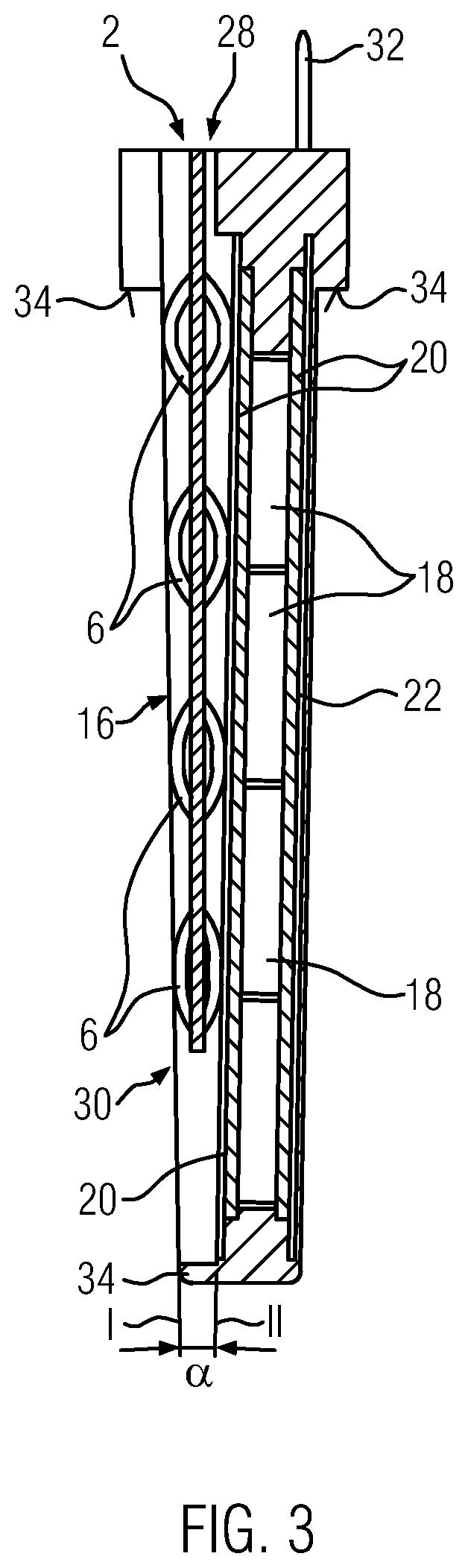

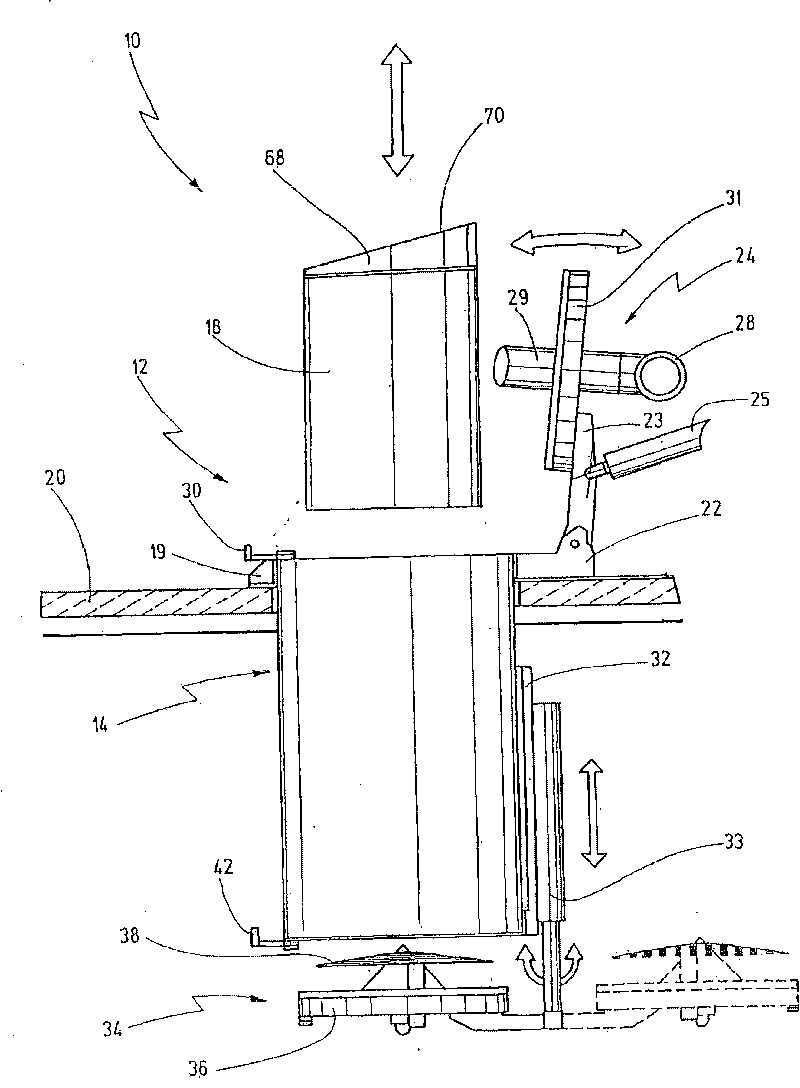

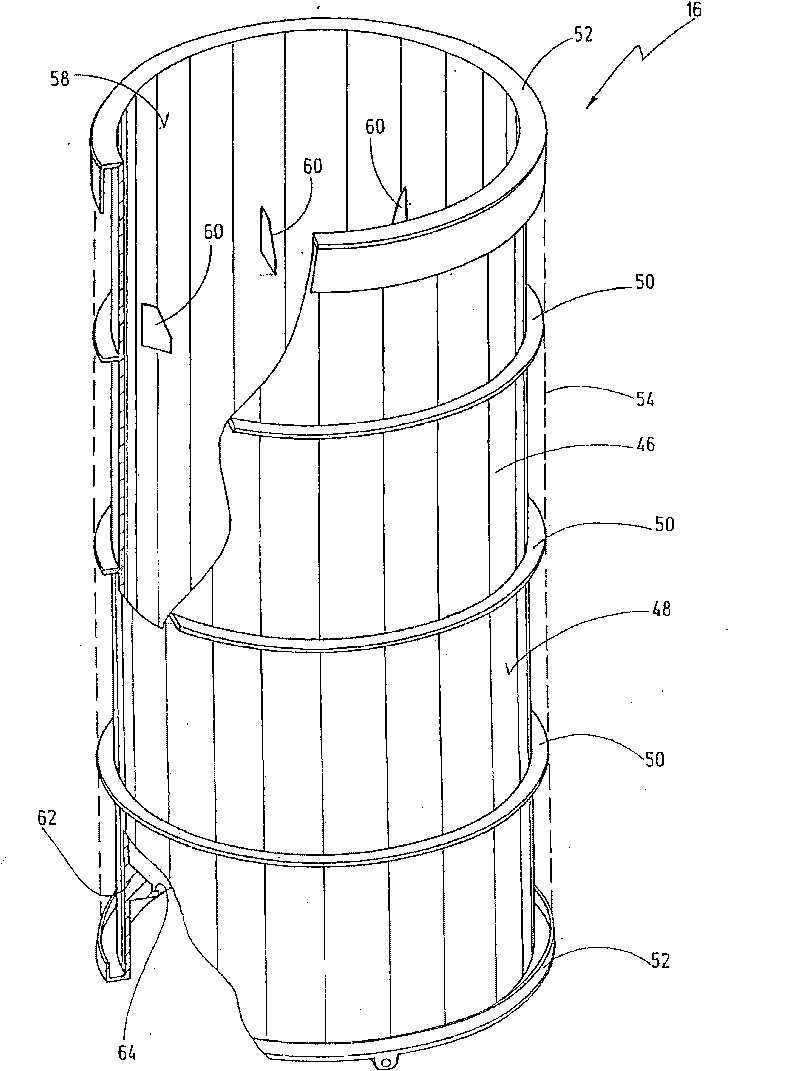

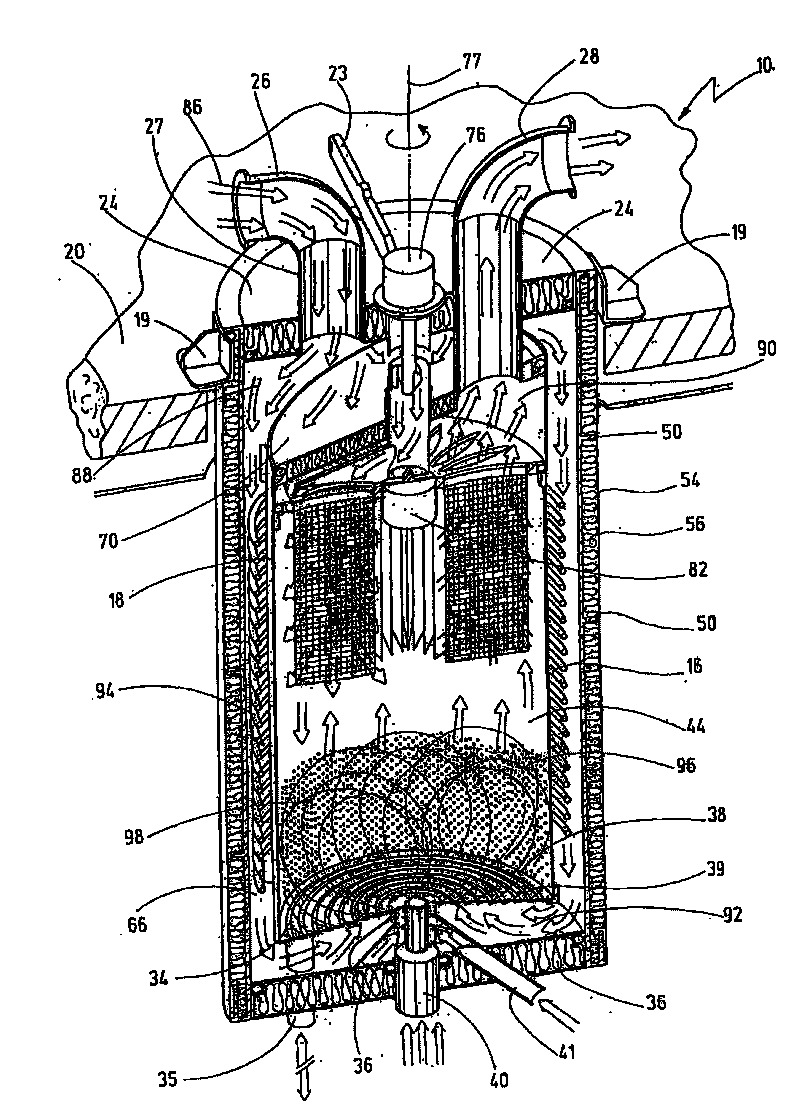

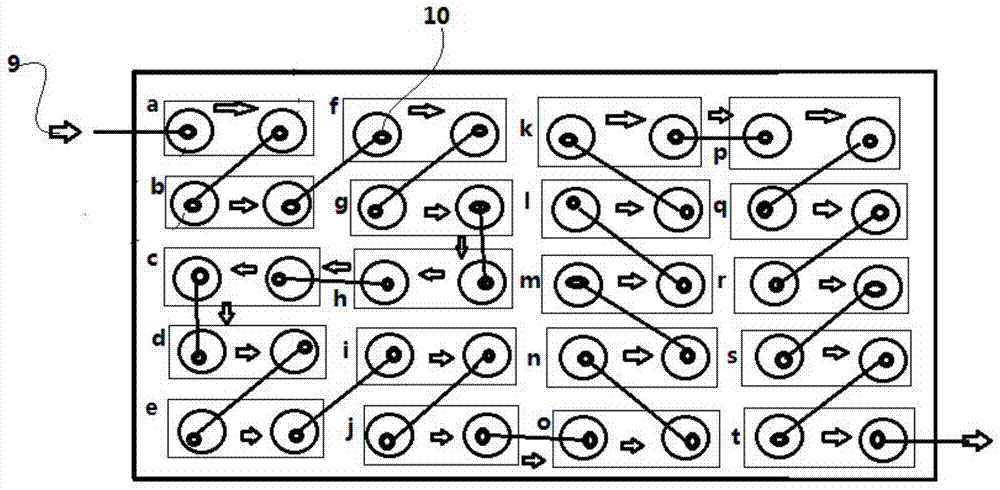

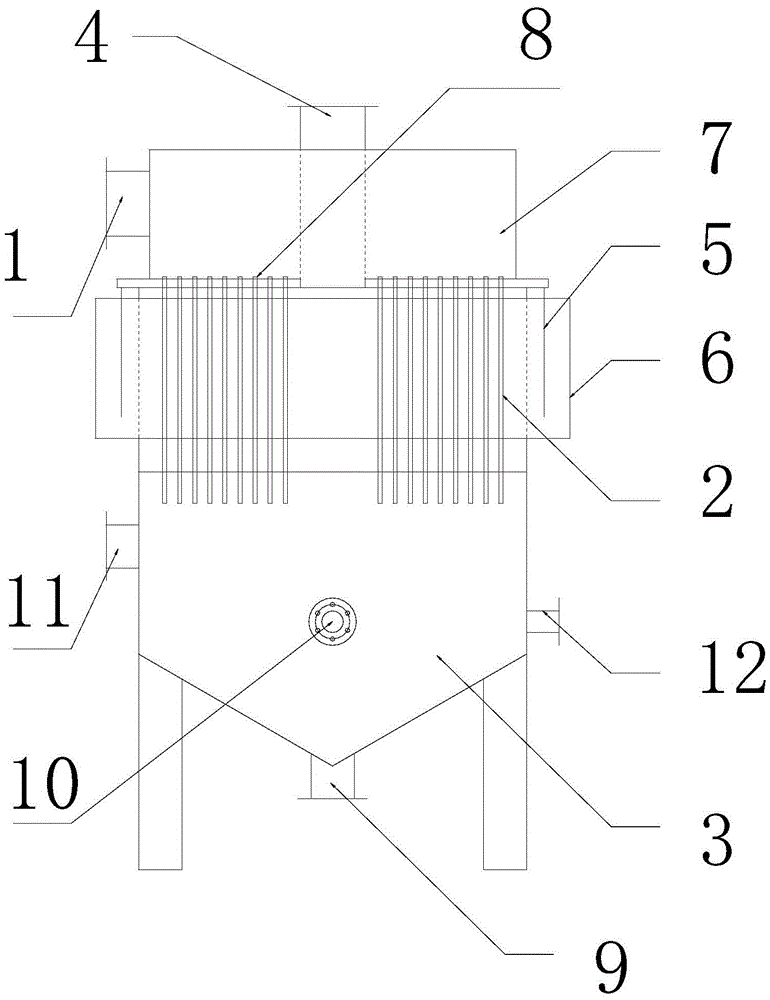

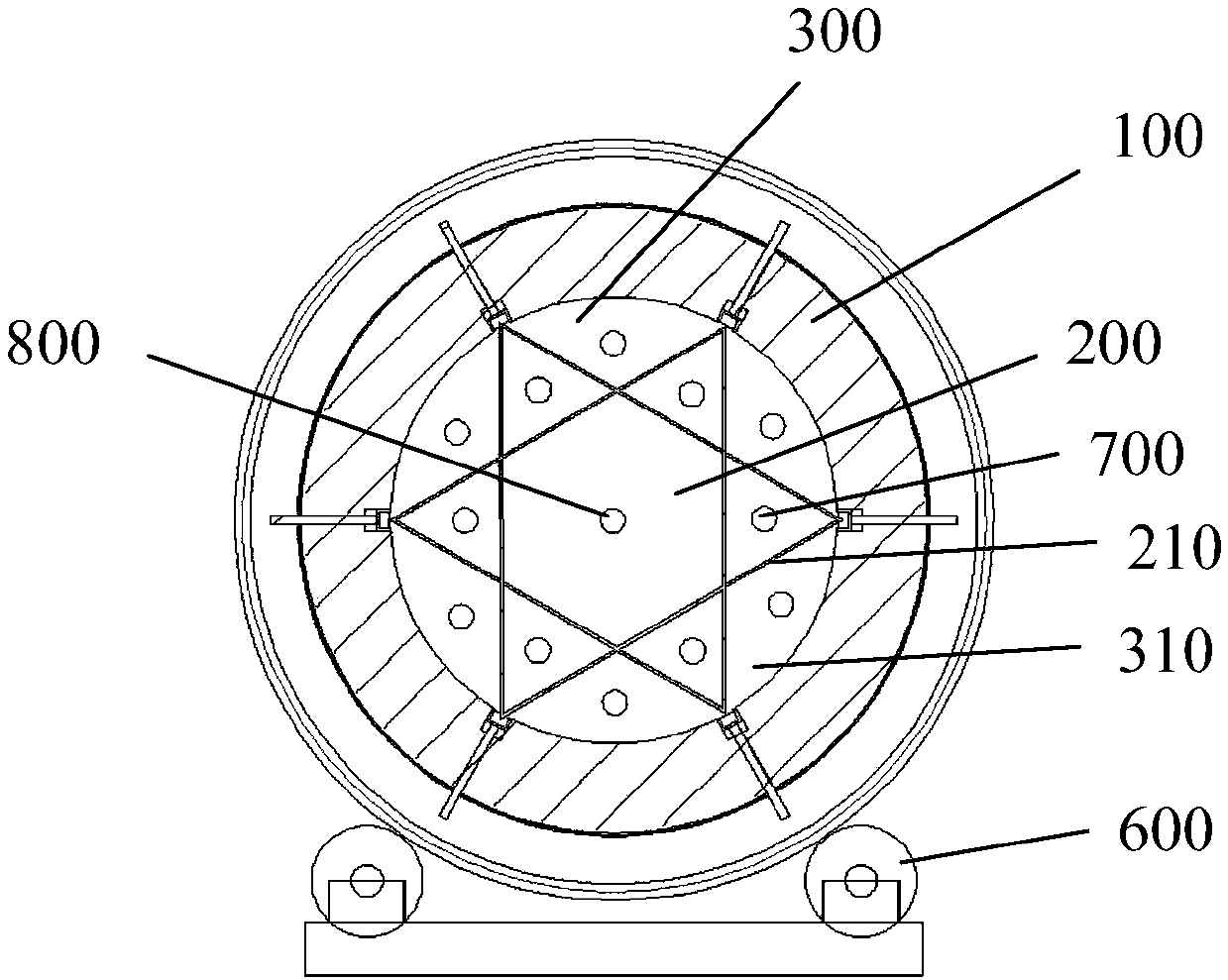

Device for treating particulate material

ActiveCN101711181AGood heat transferEconomic Process GuidanceGranulation by powder suspensionEngineeringParticulate material

A device for treating particulate material (98), comprises a housing (12), a process chamber (44) for accommodating and treating the material (98), a base (34) provided with through openings for the process air (86), a lid (24) with an outlet (28) and an inlet (26) for the process air (86) and a wall (14) enclosing the circumference of the process chamber (44). The wall (14) comprises an inner wall (18) and an outer wall (16) at a radial separation therefrom, the inlet (26) for the process air (86) is arranged in the lid (24) and opens out in a cavity (66) formed between the inner (18) and outer wall (16) with a flow connection to the through openings in the base (34). According to the invention, the outer wall (16) is designed as a static supporting housing wall, the lid (24) is supported by the outer wall (16) and the inner wall (18) is designed for rapid heat transfer.

Owner:ROMACO INNOJET

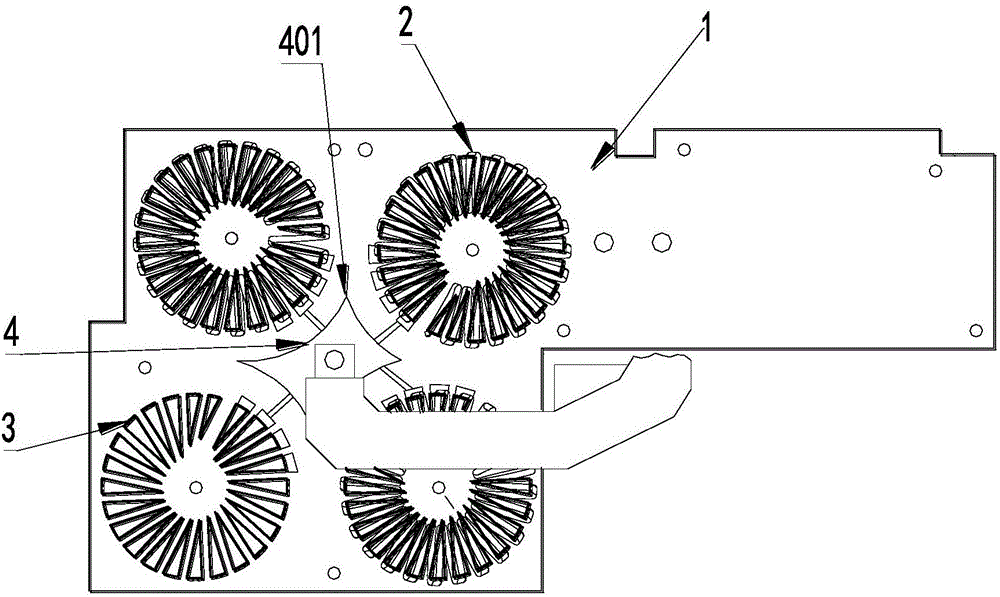

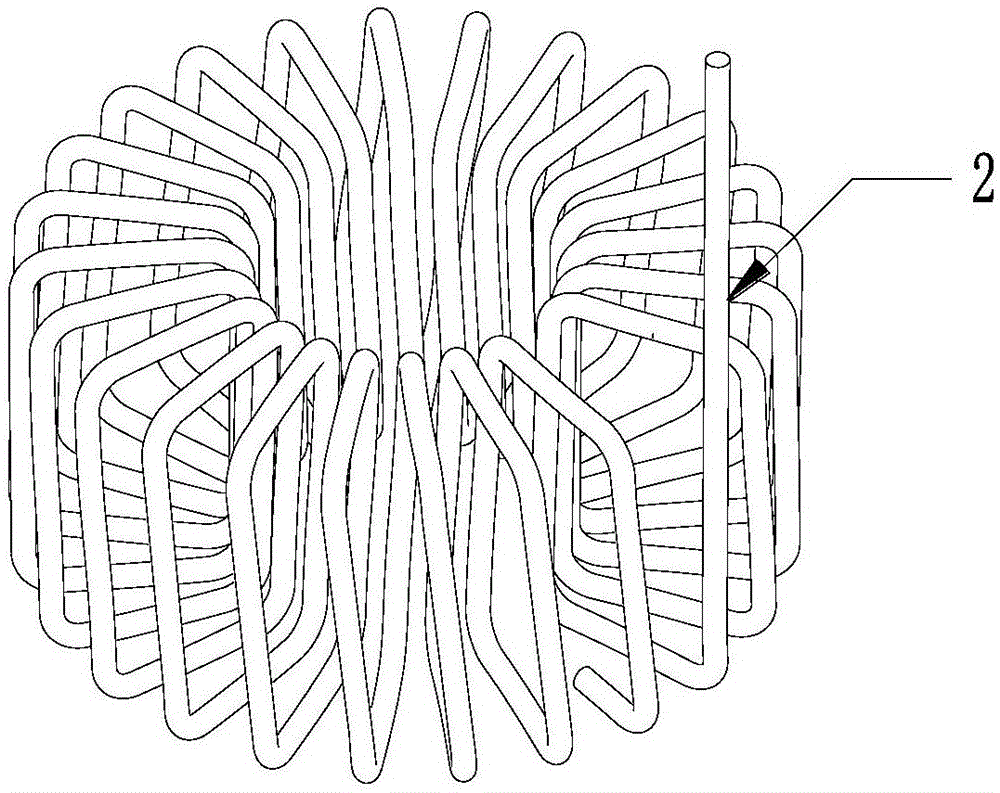

Array-type adjustable cage-type PCB inductor

ActiveCN106558400AGood heat transferLarge adjustable rangeTransformers/inductances coolingTransformers/inductances coils/windings/connectionsInductorElectrical and Electronics engineering

The invention discloses an array-type adjustable cage-type PCB inductor. A PCB is provided with a plurality of cage-type annular coils which are arranged in a matrix manner, the cross section of the annular body of each cage-type annular coil is rectangular or trapezoidal, and turns of coils of each cage-type annular coil are welded on the PCB through triangular strip pads which have the same number as the turns of coils and correspond to the turns of coils in position; the position, on the PCB, of the central part of a polygon formed by the plurality of cage-type annular coils is provided with a center pad, and the center pad is connected with any triangular strip pad connected with each cage-type annular coil. According to the invention, gaps are left among turns of each cage-type annular coil, and are benefit for heat dissipation; by arranging the triangular strip pads, when the inductor is welded on the PCB, 1 / 3 length of each turn of inductor coil is welded on the PCB, and the coils are fixed well; multiple areas are welded on the PCB, the thermal transmission effect is better; when the inductance value is adjusted, the user only needs to take out different triangular strip pads and connect the triangular strip pads to the center pad, the inductance value adjustable scope is large, the relative inductance value is obtained accurately, and the array-type adjustable cage-type PCB inductor is simple to operate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

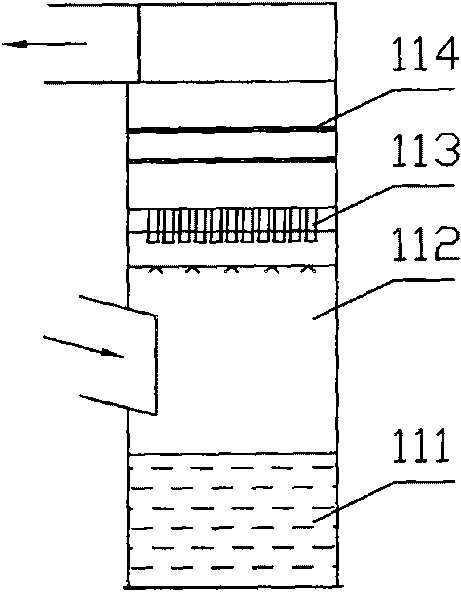

A water circulation cooling device for mercury vapor

InactiveCN105132716BImprove cooling effectRealize circulating coolingVapor condensationCooling towerContact time

The invention relates to the technical field of mercury vapor cooling, and particularly relates to a device for cooling mercury vapor through water circulation. By improvement of the structure of the cooling device, the device comprises a tank, a cooling tower arranged on the tank, an inlet formed in the side surface of the tank and an outlet formed at the side surface opposite to the inlet and at the skew diagonal position of the inlet, and further causes the water circulation cooling of the mercury vapor to be realized, the contact time of water and the vapor to be relatively long and a heat exchange degree to be relatively high; and through reasonable design of the device, a vapor circulation pipe is arranged in a cooling water pipeline in a sleeving manner, the probability of leaking the mercury vapor to environments and polluting and corroding the outer wall of the cooling tower by the mercury vapor is relatively low, the emission rate of the mercury vapor and the environment pollution rate are reduced, and the cooling effect of the mercury vapor is improved.

Owner:贵州蓝天固废处置有限公司

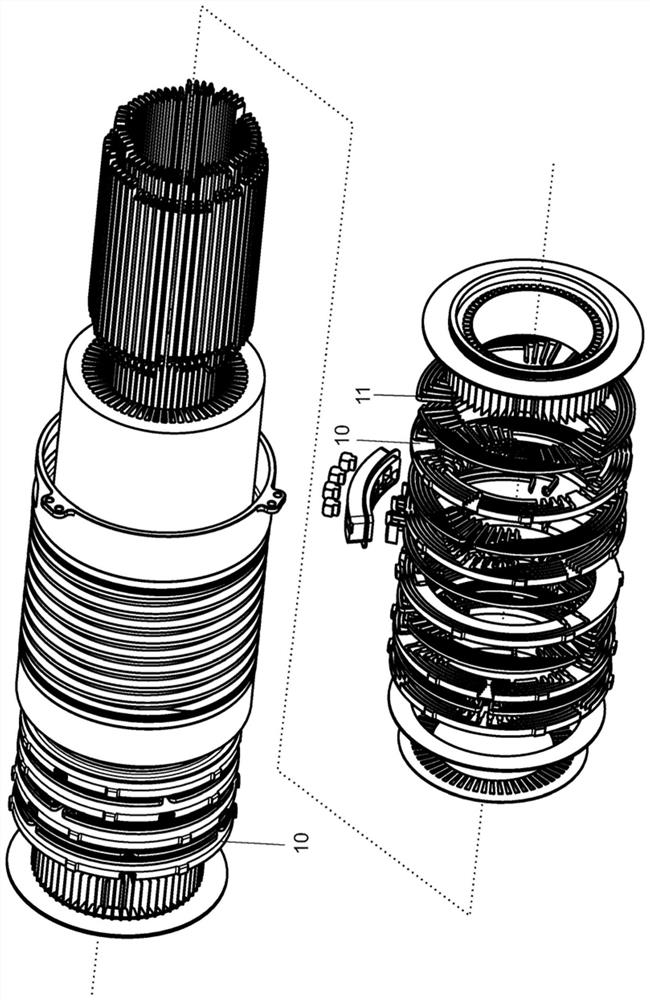

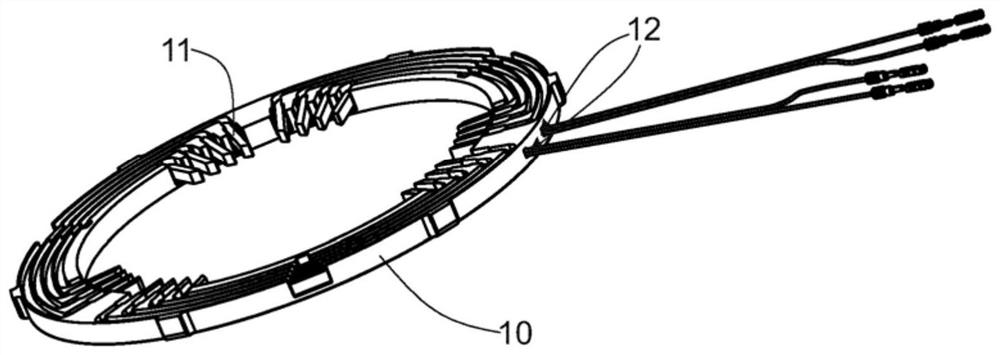

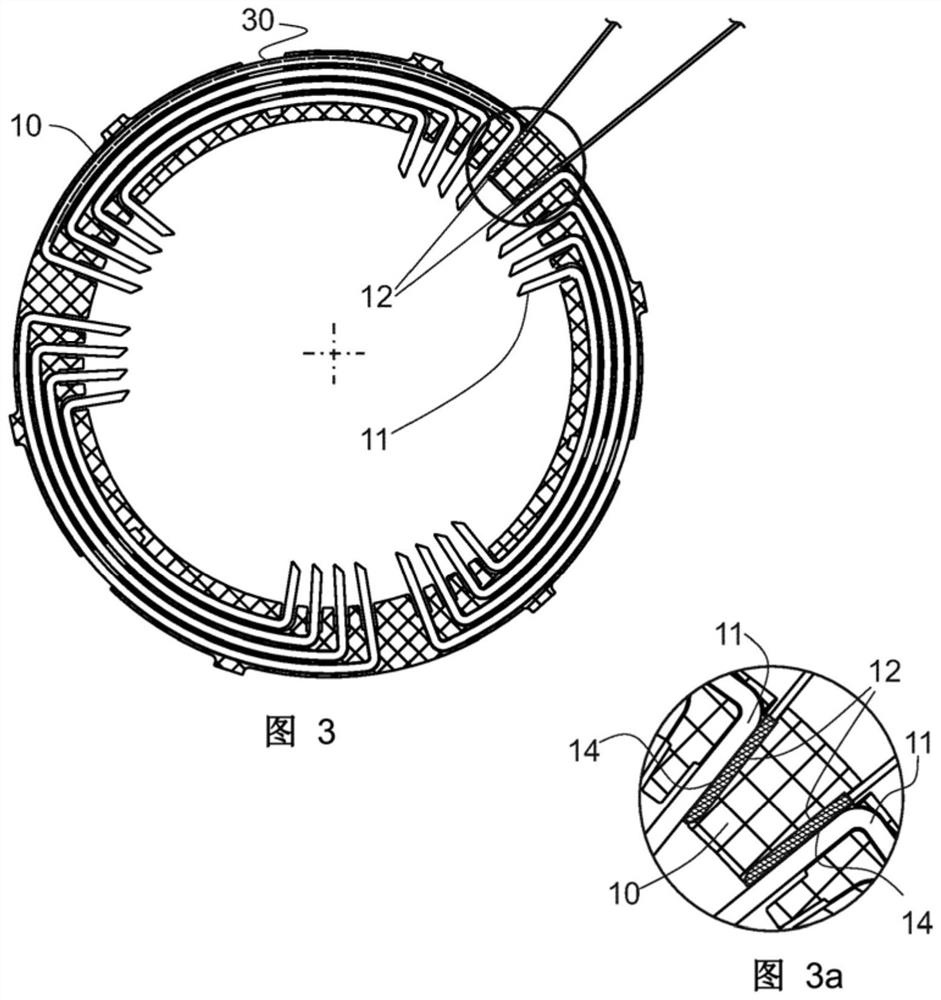

Stator and electric machine

PendingCN113261184AGood heat transferAccurate temperature measurementThermometer detailsWindings insulation shape/form/constructionPhysicsMechanical engineering

The invention relates to a stator comprising at least one insulation disk (10), at least one interconnection piece (11) and at least one temperature sensor (12); the insulation disk (10) includes a holding element (13) for the temperature sensor (12), and the interconnection piece (11) includes a contact surface (14) for the temperature sensor (12); at least part of the interconnection piece (11) and at least part of the temperature sensor (12) are arranged and retained in the holding element (13); and the temperature sensor (12) is at least partially in planar contact with the contact surface (14) and is pressed against the contact surface (14) by a spring force and / or a clamping force.

Owner:汉拿电驱动股份有限公司

Exhaust gas purification device

InactiveCN104324569BUniform air distributionPrevent leakageUsing liquid separation agentChemical industryProcess engineering

The invention discloses a tail gas purification device and in particular discloses a tail gas purification device used in the field of chemical industry. The tail gas purification device has the advantages that energy can be saved, carbon black tail gas can be effectively purified, the purification process is safe and efficient, and the tail gas purification device is convenient to manufacture, mount, maintain and wash. The tail gas purification device comprises a bubbler and an absorption liquid container, wherein the bubbler comprises a tail gas inlet and a bubbling pipe; one end of the bubbling pipe is communicated with the tail gas inlet; the other end of the bubbling pipe extends into the absorption liquid container; the tail gas purification device also comprises a tail gas outlet; the tail gas outlet is communicated with the absorption liquid container; one end of the bubbling pipe is communicated with the tail gas inlet and the other end of the bubbling pipe extends into the absorption liquid container, so that the tail gas can enter the absorption liquid container by virtue of the bubbling pipe so as to be purified, and thus the tail gas leakage is effectively avoided; the tail gas outlet is communicated with the absorption liquid container, so that purified tail gas enters the next process by virtue of the tail gas outlet; a water seal cylinder is matched with a water seal tank to realize water sealing, so that the tail gas leakage can be effectively avoided.

Owner:PANZHIHUA GANGCHENG GROUP RUITONG REFRIGERATION EQUIP

Fin type heat exchanger convenient to clean

PendingCN114152138ARelieve pressureSteady diversionMachines/enginesEngine componentsInlet pressureMechanical engineering

A water inlet pressure-bearing pipe for reducing water inlet pressure is fixedly connected to one side end of a heat exchanger body, and a water outlet pressure-bearing pipe for reducing water outlet pressure is fixedly connected to the position, corresponding to the water inlet pressure-bearing pipe, of the other side end of the heat exchanger body. A water inlet pressure-bearing flange for bearing water inlet pressure is fixedly installed at the position, close to the heat exchanger body, of one side end of the water inlet pressure-bearing pipe, a water outlet pressure-bearing flange for bearing water outlet pressure is fixedly installed at the position, close to the heat exchanger body, of one side end of the water outlet pressure-bearing pipe, and the water inlet pressure-bearing pipe and the water outlet pressure-bearing pipe are each provided with a semicircular pipe. The water inlet pressure-bearing pipe, the water outlet pressure-bearing pipe, the water inlet pressure-bearing flange and the water outlet pressure-bearing flange are arranged at the two ends of the heat exchanger body correspondingly, so that the heat exchanger body can reduce the pressure of inlet water and outlet water to the maximum extent in the water inlet and outlet processes, the heat exchange effect of the heat exchanger body is guaranteed, and the heat transfer effect of the heat exchanger body is enhanced.

Owner:苏州荣轩环保有限公司

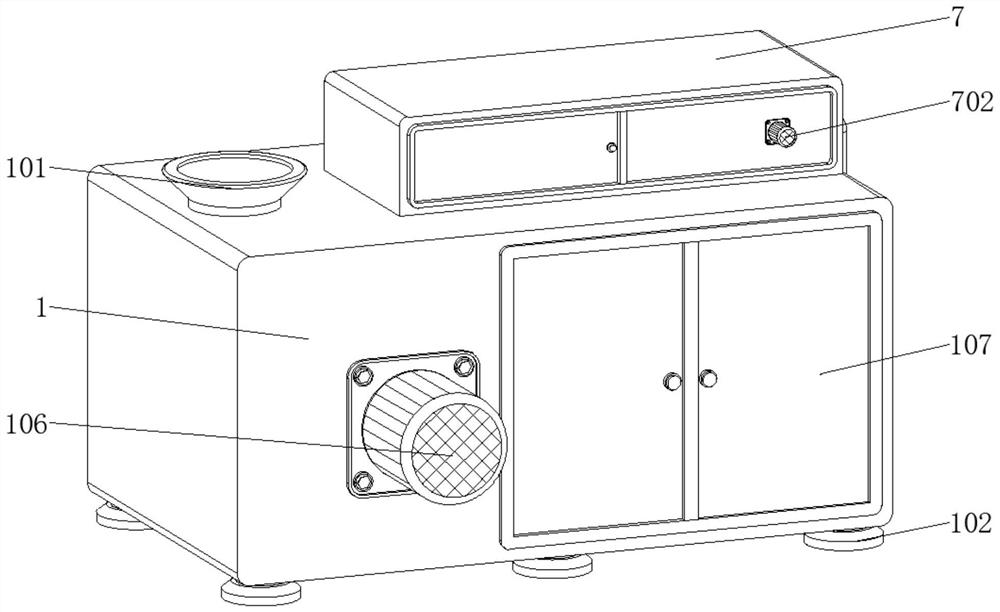

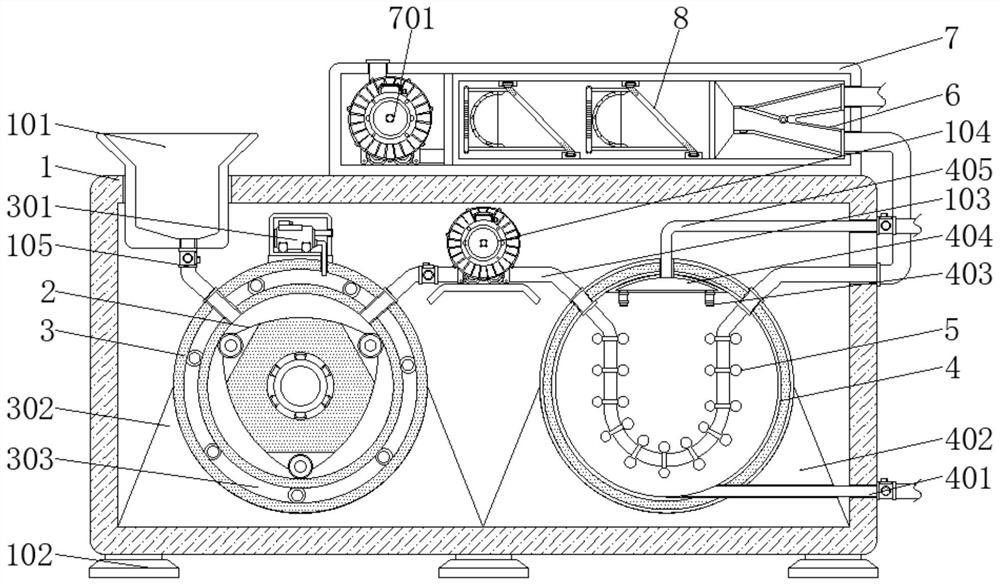

A blast furnace slag dry processing device based on high temperature slag waste heat recovery

ActiveCN113699287BGood heat transferImprove insulation effectRecycling and recovery technologiesDust controlVacuum chamber

The invention discloses a blast furnace slag dry processing device based on high-temperature slag waste heat recovery, comprising a shell, a grinding component, a diversion component and a dust removal component. There is a vacuum chamber, a grinding assembly is installed inside the grinding chamber, a rotor is installed in the grinding assembly, a drive shaft is installed at both ends of the rotor, three sets of installation grooves are installed on the outer side of the rotor, and the inner side of the casing away from the grinding chamber is installed with a heat exchange compartment. In the invention, a rotor is installed inside the grinding chamber, and the surrounding components can be driven by the rotor to rotate synchronously, so that the blast furnace slag inside the grinding chamber can be driven to move, and the blast furnace slag can be processed by the cooperation of the rotor and the inner wall of the grinding chamber. Crushing and grinding, so that the blast furnace slag with irregular shape and size can be pulverized into fine high-temperature powder, so that the heat exchange heat treatment inside the blast furnace slag can be facilitated.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

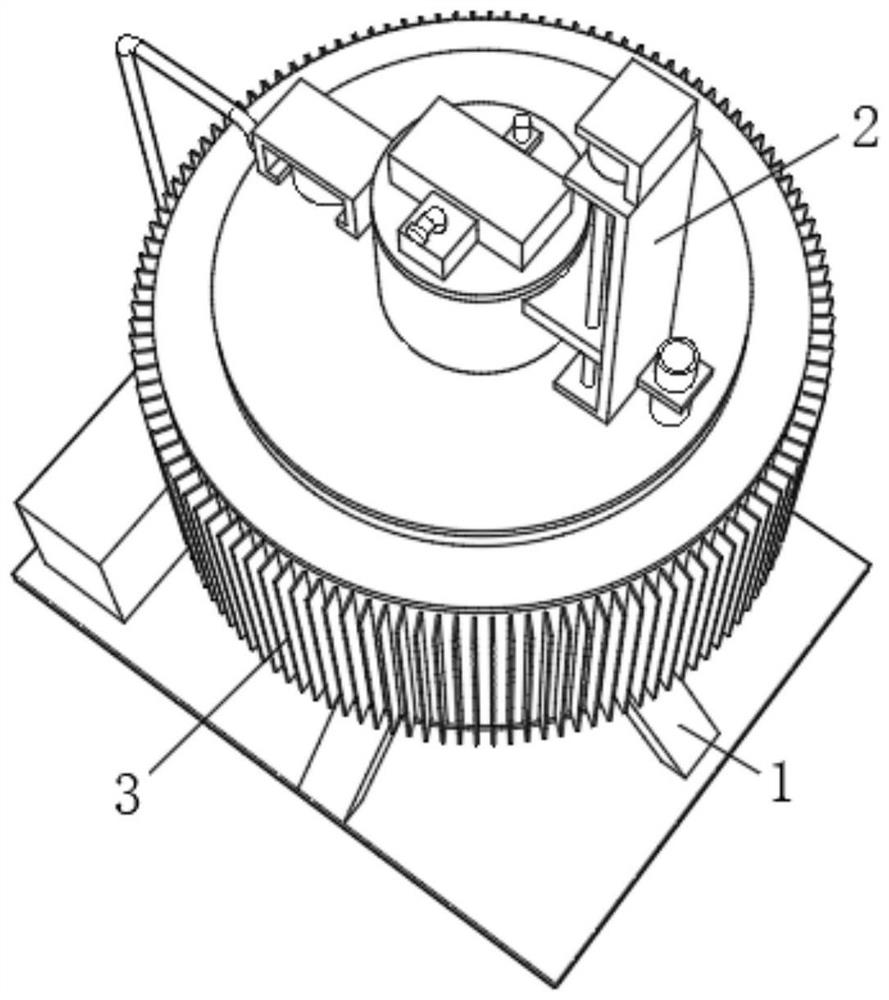

Multi-cavity activation furnace

PendingCN107601503AGood heat transferIncrease contact rateCarbon compoundsActivated carbonEngineering

The invention discloses a multi-cavity activation furnace. The multi-cavity activation furnace comprises a furnace body, a hollow heating channel is axially arranged at the internal axle center of thefurnace body, an inner activation cavity is formed between the outer wall of the heating channel and the inner wall of the furnace body , the heating channel is formed by encircling and splicing theleft and right ends of N same plates, the cross section of the heating channel has an N-regular-polygon-shaped shape, the left and right ends of every plate respectively outwards extend into the innerwall of the furnace body, and the extending plates divide the inner activation cavity into a plurality of activation sections. The internal of the furnace body forms a structure with the internal being the heating furnace and the external being the inner activation cavity through the plates, and the plates are integrally molded and can well transfer heat and greatly improve the contact rate of acarbonized material and the plates, so activated carbon has the advantages of high yield, high quality and good quality.

Owner:浙江瑞能炭材料科技有限公司

Rapid cooling device for chemical production

InactiveCN112797817AImprove heat transfer efficiencyShorten cooling timeDirect contact heat exchangersHeat transfer modificationEngineeringProcess engineering

The invention belongs to the technical field of chemical production, and discloses a rapid cooling device for chemical production. The rapid cooling device for chemical production comprises a storage mechanism, a first cooling mechanism and a second cooling mechanism. According to the rapid cooling device for chemical production, through mutual cooperation of the first cooling mechanism and the second cooling mechanism, chemicals carried in a storage tank can be subjected to internal and external synchronous cooling treatment; cooled compressed air is evenly dispersed in the storage tank in a bubble shape from the inner part of a cooling cylinder through small holes in stirring rods, so that the heat exchange area of the compressed air and the chemicals is increased, rapid cooling of the chemicals is achieved; a baffle plate with a cavity is arranged below a fixing plate, and the rapid cooling of the chemicals at the position without the stirring rods below the fixing plate is achieved, so that the time consumed for cooling the chemicals is greatly shortened, the heat exchange effect of the chemicals is better, and the production quality is improved.

Owner:蒋广

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com