An inboard heat exchanger suitable for underwater equipment

A heat exchanger and equipment technology, applied in the field of heat exchange equipment, can solve the problems of occupying cabin space, large volume and weight, poor heat transfer capacity, etc., and achieve the effects of convenient operation, reducing complexity and improving heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

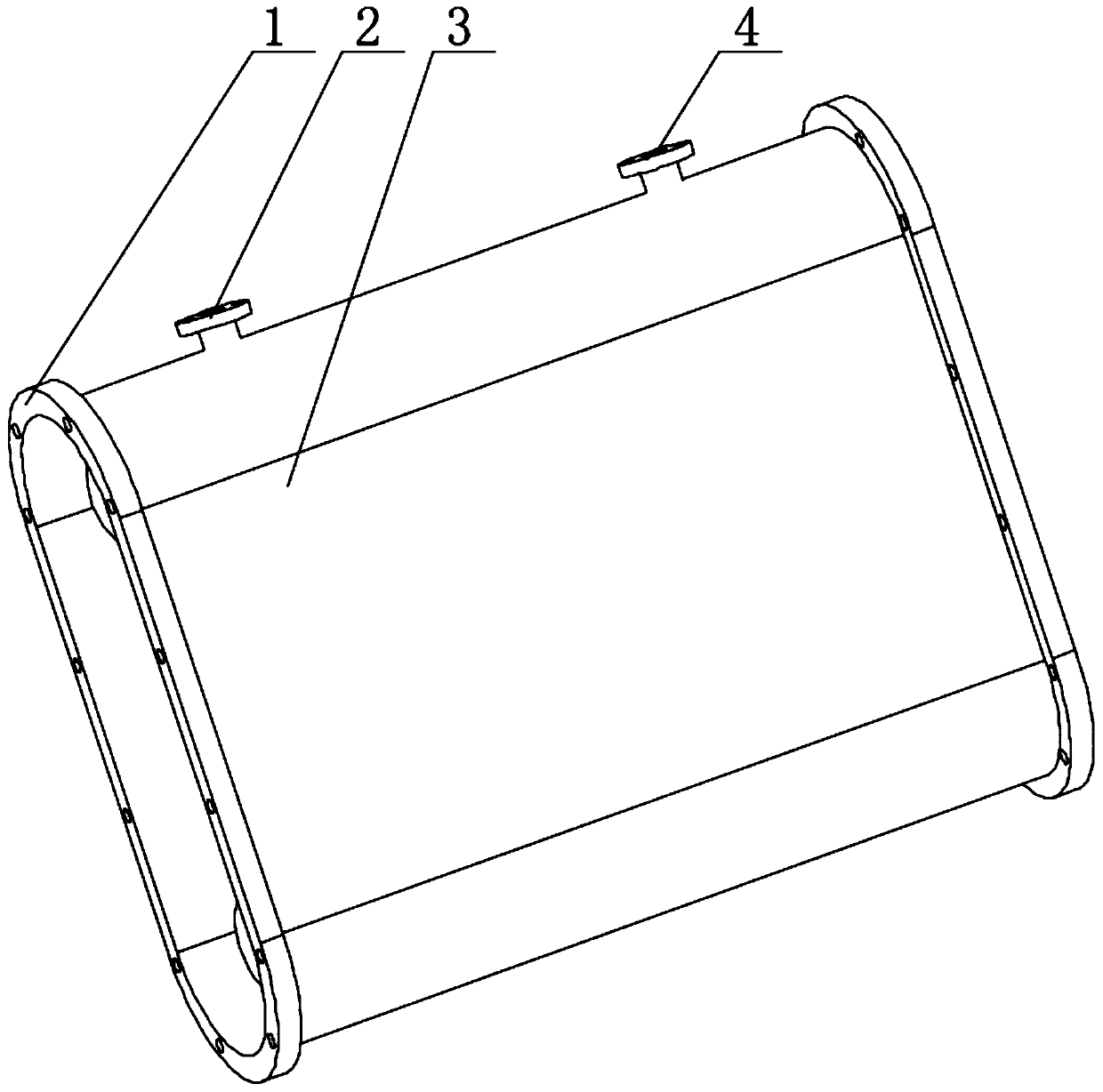

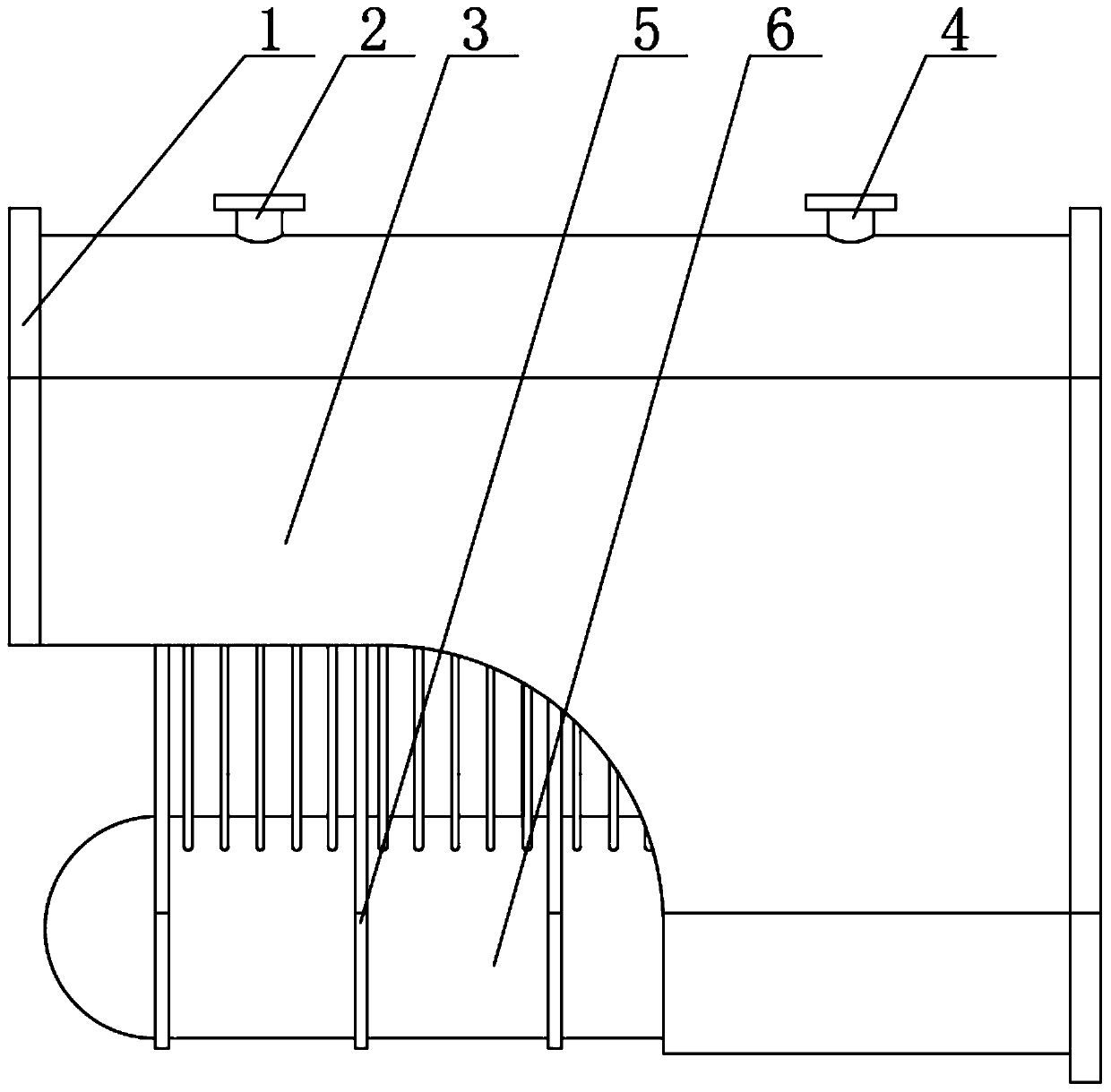

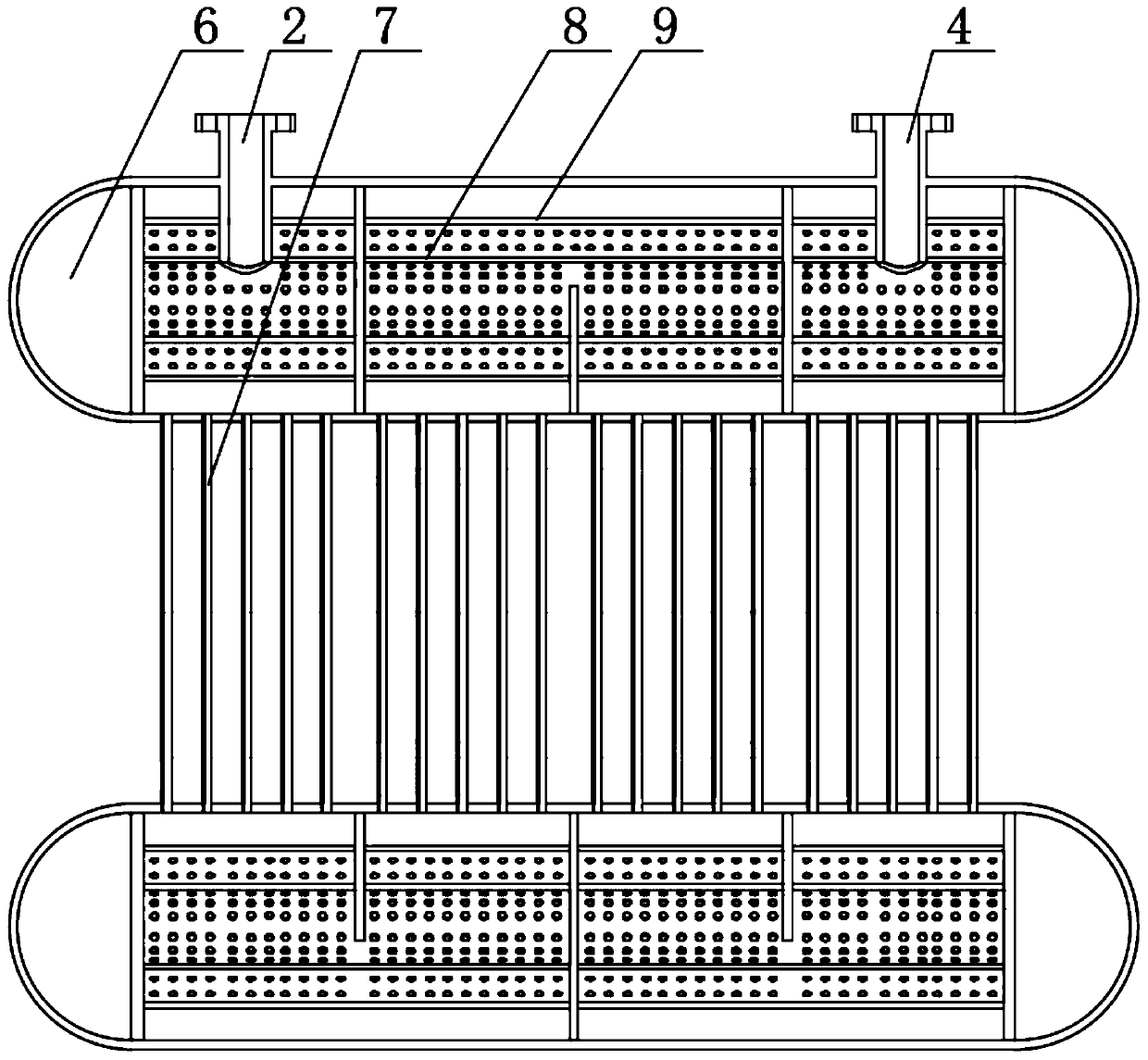

[0028] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the inboard heat exchanger suitable for underwater equipment in this embodiment includes a shell side shell 3, the cross section of the shell side shell 3 is an elliptical structure, and two ends of the shell side shell 3 are installed respectively The end cover 1, the structure of the end cover 1 matches the cross-sectional shape of the shell side shell 3, and the fresh water inlet joint 2 and the fresh water outlet joint 4 are arranged at intervals on the top of the shell side shell 3, and the interior of the shell side shell 3 is arranged at intervals up and down There are pipe box cylinders 6, a single pipe box cylinder 6 is arranged horizontally, and the two pipe box cylinders 6 are connected and fixed by a plurality of spaced frames 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com