Heat exchanger suitable for multi-pressure-resistant shell underwater equipment and using method of heat exchanger

A pressure-resistant shell and heat exchanger technology, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of poor heat transfer capacity, occupied space in the cabin, large volume and weight, etc. , to achieve the effect of increasing turbulence, convenient operation and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

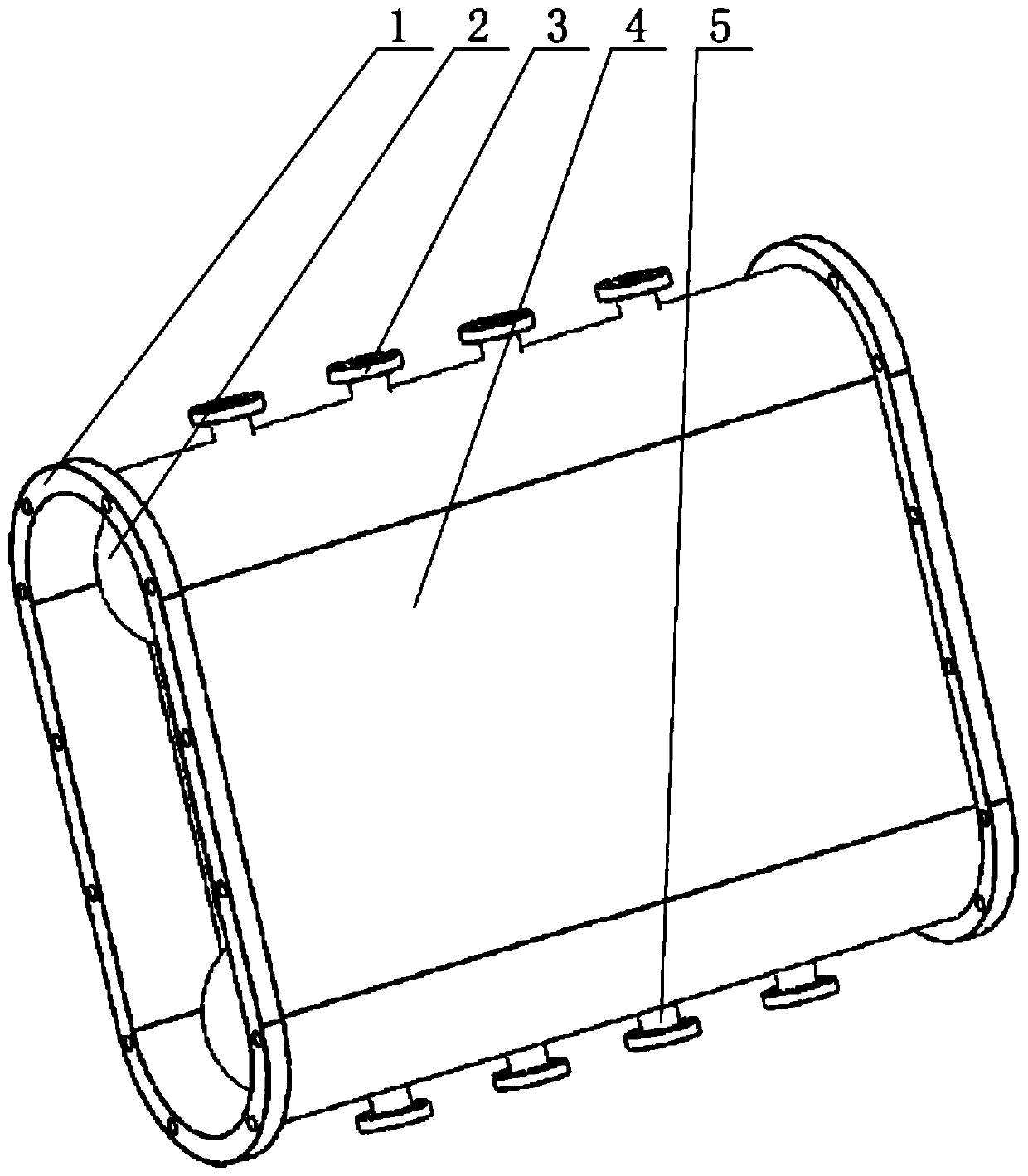

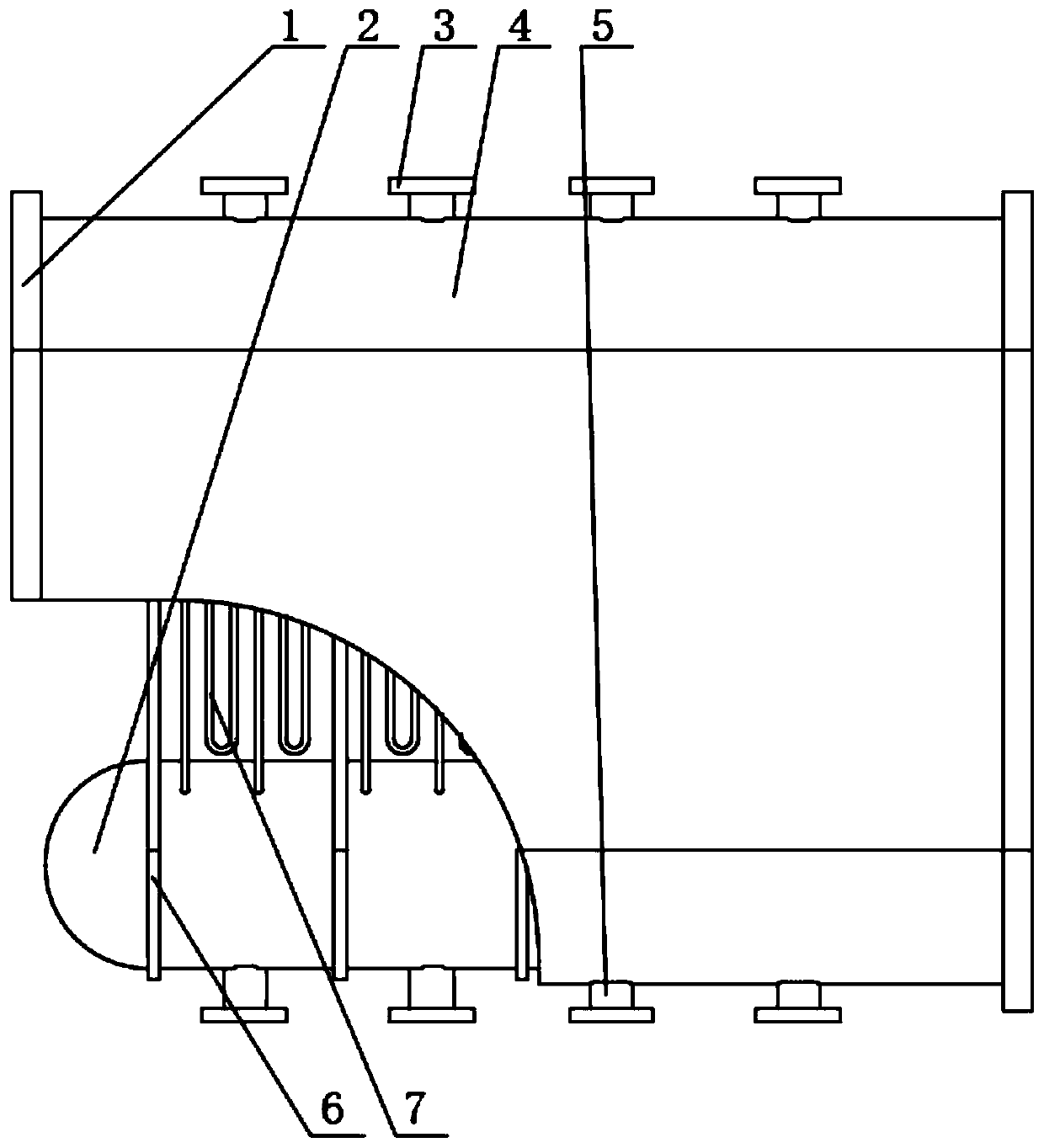

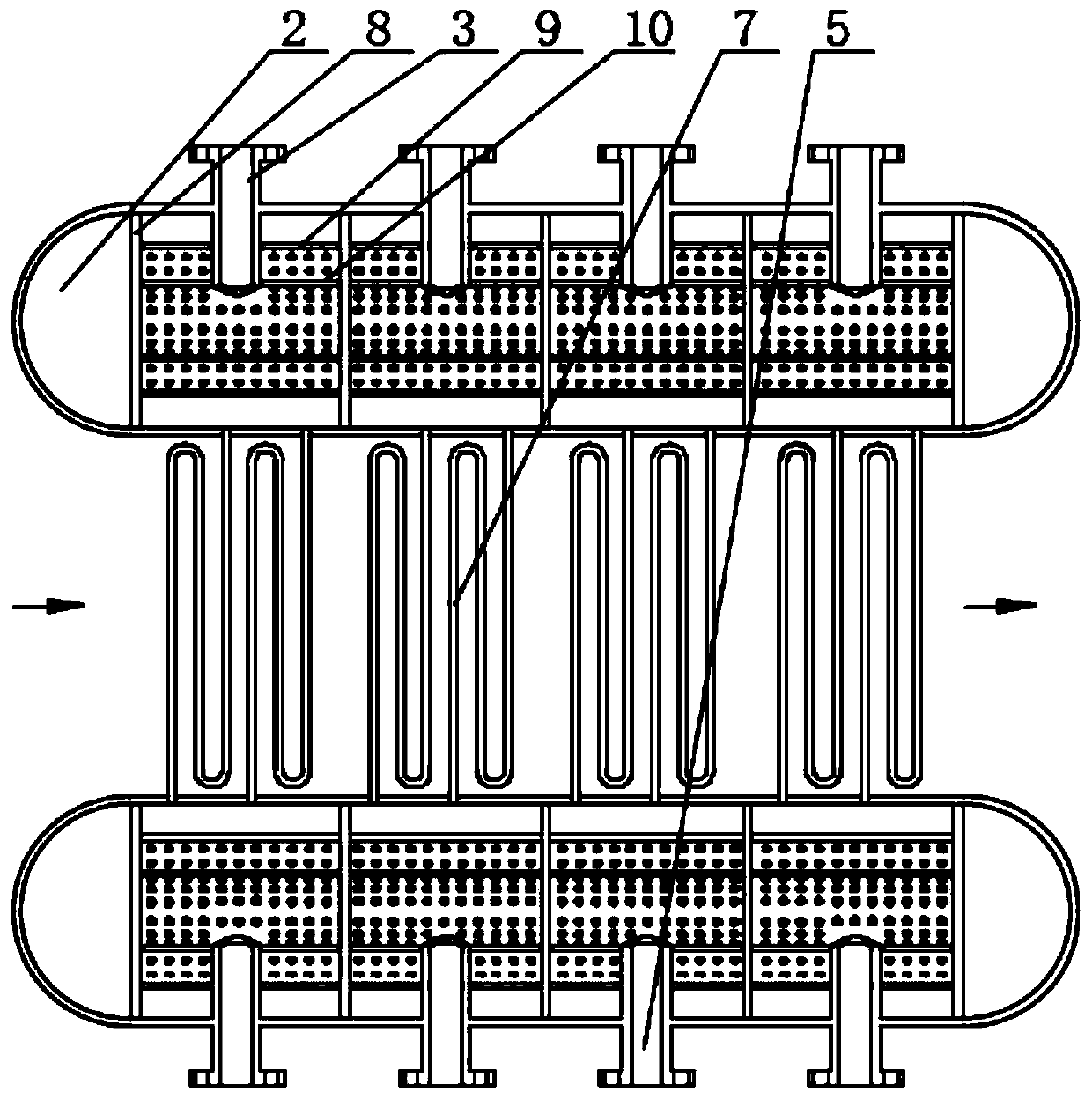

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the heat exchanger suitable for multi-pressure shell underwater equipment in this embodiment includes tube box cylinders 2 arranged in parallel at intervals up and down, two tube box cylinders 2 are arranged horizontally, and two tube box cylinders The cylinders 2 are supported and installed by multiple frames 6, and the two tube box cylinders 2 are connected by heat exchange tube bundles 7. The outside of the frame 6 is surrounded by a shell 4 that penetrates left and right, and the left and right ends of the shell 4 are openings. , an end cover 1 is installed at the opening, a plurality of fresh water outlets 3 are provided on the top surface of the housing 4 , and a plurality of fresh water inlets 5 corresponding to the fresh water outlets 3 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com