A blast furnace slag dry processing device based on high temperature slag waste heat recovery

A blast furnace slag, dry processing technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problem of small contact area between blast furnace slag and heat exchanger, inconsistent shape and size of blast furnace slag, and reducing the heat energy conversion speed of the device. and other problems to achieve the effect of increasing energy utilization, improving thermal insulation performance, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

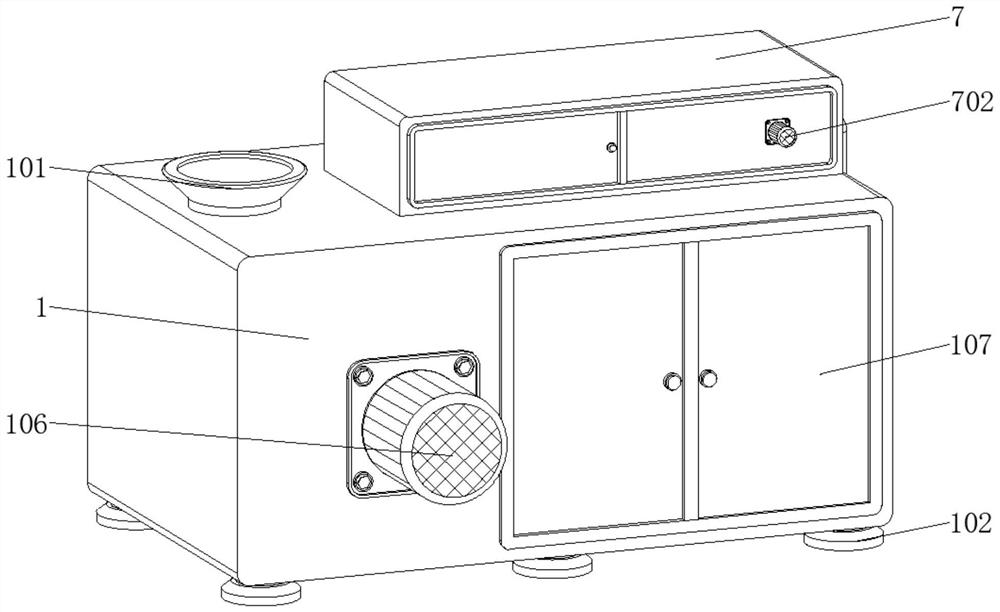

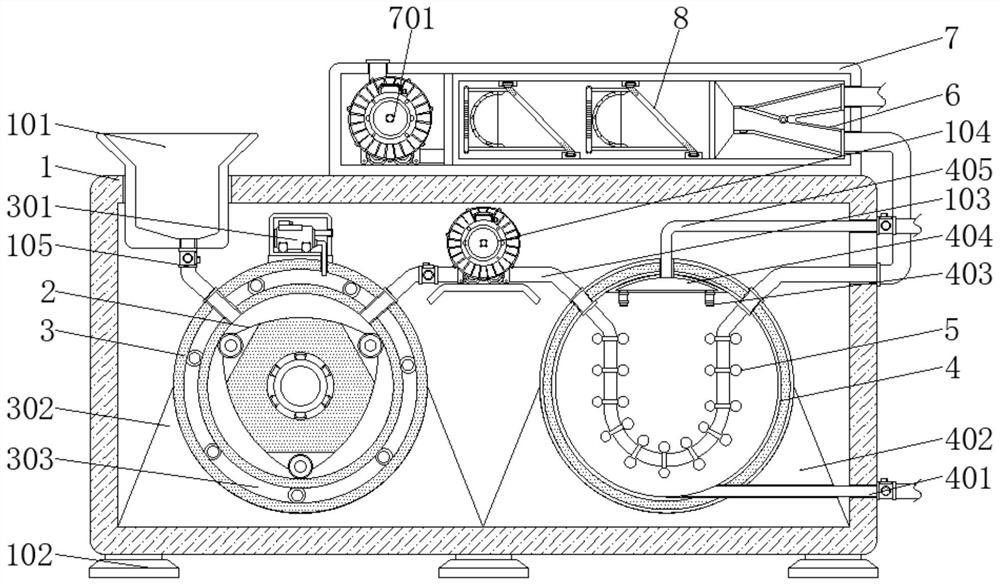

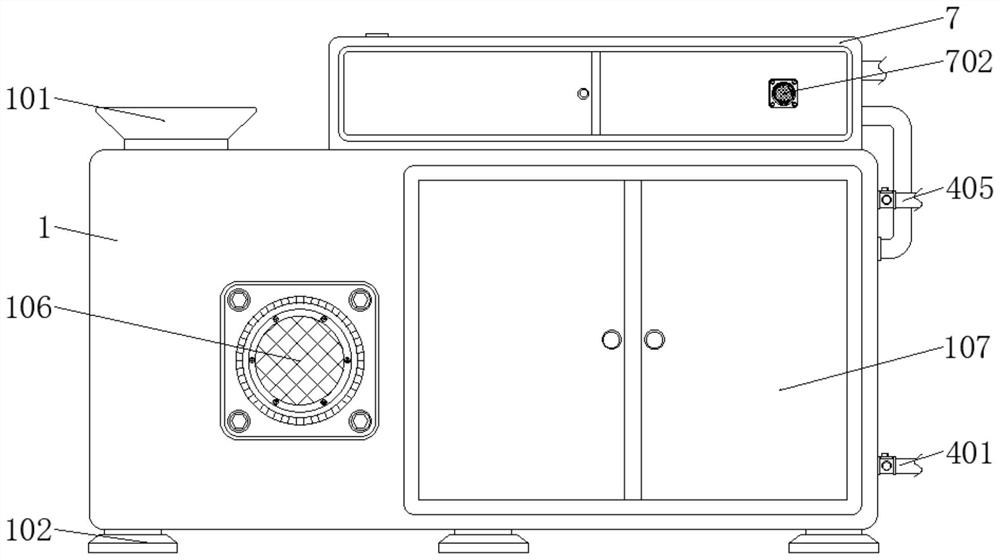

[0033] see Figure 1-7, a blast furnace slag dry processing device based on high-temperature slag waste heat recovery proposed by the present invention includes a shell 1, a grinding assembly 2, a diversion assembly 6 and a dust removal assembly 8. The bottom of the shell 1 is equidistantly installed with three groups of supports The seat 102, the housing 1 can provide the installation position for the surrounding components, the support seat 102 can support and fix the bottom of the housing 1, so as to improve the overall stability of the device, an access door is installed on the front side of the housing 1 107. The access door 107 can open the front side of the housing 1, so as to facilitate the maintenance of the components inside the housing 1. The side of the front of the housing 1 away from the access door 107 is installed with a servo motor 106, and the servo motor The output end of the 106 extends to the inside of the grinding chamber 3 and is fixedly connected to the...

Embodiment 2

[0035] see Figure 1-4 , a blast furnace slag dry processing device based on high temperature slag waste heat recovery proposed by the present invention, compared with the first embodiment, this embodiment also includes a fixed seat 302 installed at the bottom of the grinding chamber 3, and the fixed seat 302 can be used for grinding The bottom of the chamber 3 is limited and fixed, thereby increasing the installation stability of the grinding chamber 3, and a vacuum pump 301 is installed on the top of the grinding chamber 3. The vacuum pump 301 can be of the HG-30L type. The interior is pumped, so that a low-pressure environment is formed inside the vacuum chamber 303, and the overall thermal insulation performance of the grinding chamber 3 is improved. A rotor 201 is installed inside the grinding chamber 3, and the rotor 201 can drive the surrounding components to rotate, which can further improve the blast furnace. The slag is crushed and ground by applying pressure, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com