Exhaust gas purification device

A tail gas purification device and tail gas technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc., can solve the problems of continuous production difficulty, large floor space, no standardization, etc., and achieve convenient supplementation and replacement , prevent exhaust gas leakage, and facilitate heat exchange treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

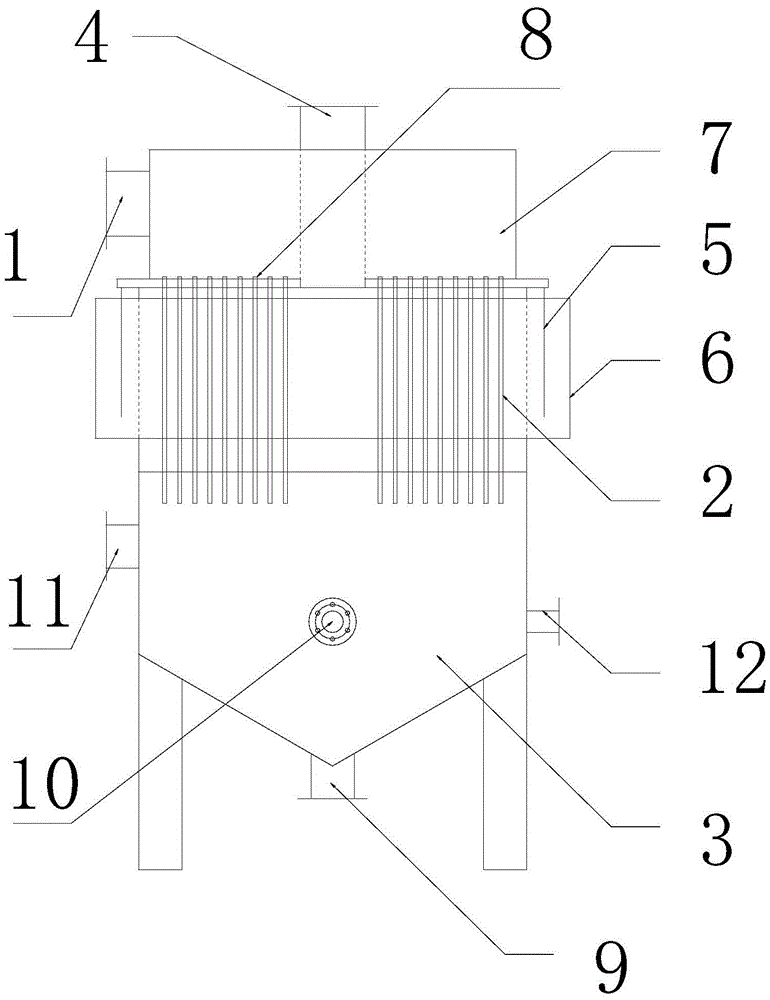

[0017] Such as figure 1 As shown, the exhaust gas purification device of the present invention includes a bubbler and an absorption liquid container, the bubbler includes an exhaust gas inlet and a bubbling tube, one end of the bubbling tube communicates with the exhaust gas inlet, and the other end extends into the absorption liquid container Among them, the exhaust gas outlet is also included, and the exhaust gas outlet is communicated with the absorption liquid container. Since one end of the bubbling tube communicates with the tail gas inlet and the other end extends into the absorbing liquid container, the tail gas enters the absorbing liquid container through the bubbling tube and is purified below the liquid surface, effectively preventing the tail gas from leaking. Since the tail gas outlet is in communication with the absorbing liquid container, the purified tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com