Multifunctional carbon-containing substance pyrolysis evaluation device and method

An evaluation device and evaluation method technology, applied in the direction of measuring device, material thermal development, material thermal analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

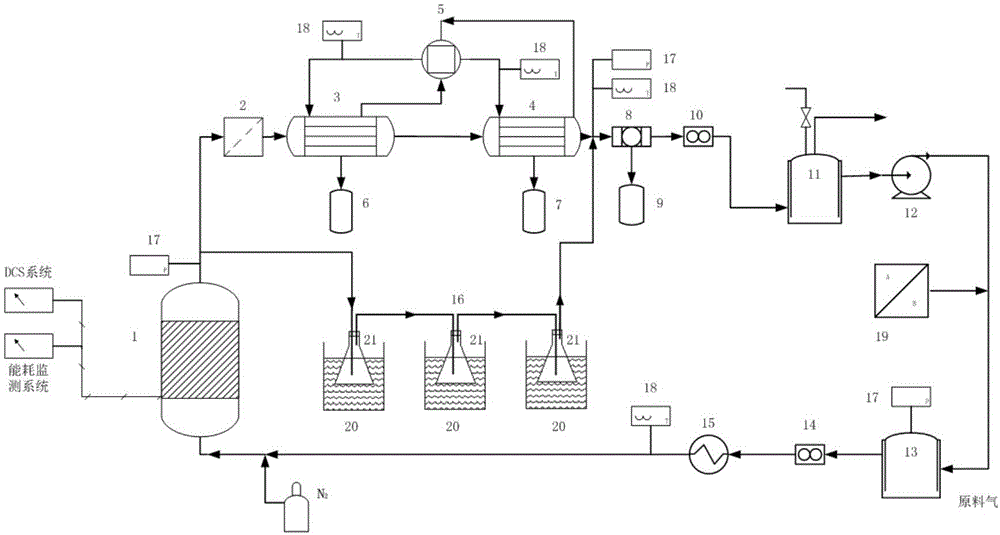

[0076] Low-temperature pyrolysis evaluation test of carbonaceous substances

[0077] Such as figure 2 As shown, block materials with a particle size of 10-50mm are put into the reactor 1, and then nitrogen gas is injected into the nitrogen purge inlet at the bottom of the reactor 1 to purify the system to achieve a hypoxic environment. The operating conditions such as the pyrolysis temperature, temperature rise program, and pyrolysis time of the reactor 1 are set through the DCS control system, and the reactor 1 is heated according to the temperature control program to perform pyrolysis reactions at different temperatures. The high-temperature (500°C-600°C) raw coal gas generated by the reaction enters the filter 2 of the main road through the pipeline with a heat tracing device to filter the dust and then enters the shell side of the primary condenser 3, and is connected with the flow from the refrigeration unit 5 The cooling medium on the tube side of the primary condenser...

Embodiment 2

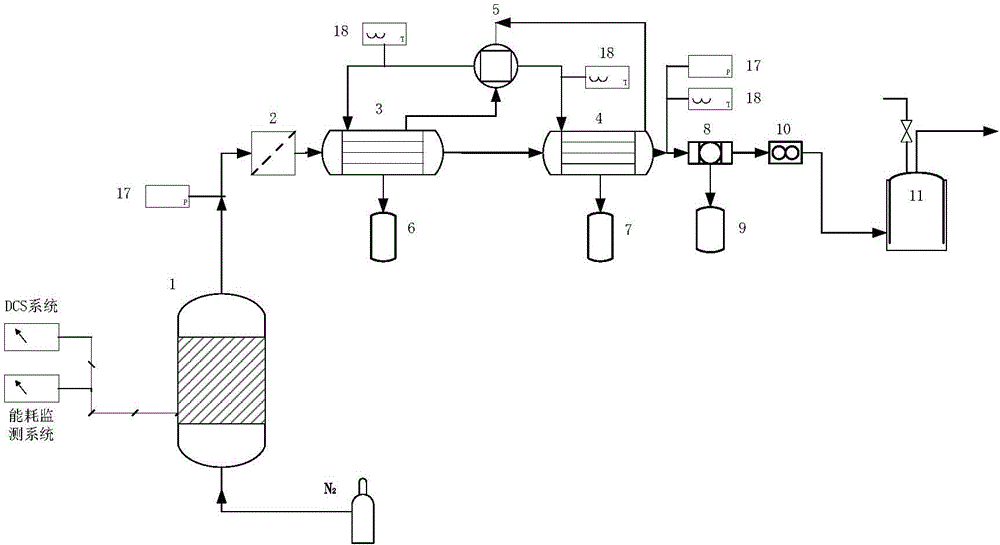

[0079] Carrying out the evaluation test of hydropyrolysis of carbonaceous substances

[0080] Such as image 3 As shown, block materials with different properties are put into the reactor 1, and then the system is purged with nitrogen gas from the nitrogen purge inlet at the bottom of the reactor 1 to achieve a hypoxic environment. The operating conditions such as the pyrolysis temperature, temperature rise program, and pyrolysis time of the reactor 1 are set through the DCS control system, and the reactor 1 is heated according to the temperature control program to perform pyrolysis reactions at different temperatures. The hydrogen-rich gas of hydropyrolysis can be provided by the gas distribution system or pumped out by the circulation pump 12 from the existing pyrolysis gas in the gas storage tank 11 and the mixed gas supplemented by the gas distribution system. The gas enters the gas mixing tank 13 and the second flowmeter 14 to adjust the flow rate (which can realize the ...

Embodiment 3

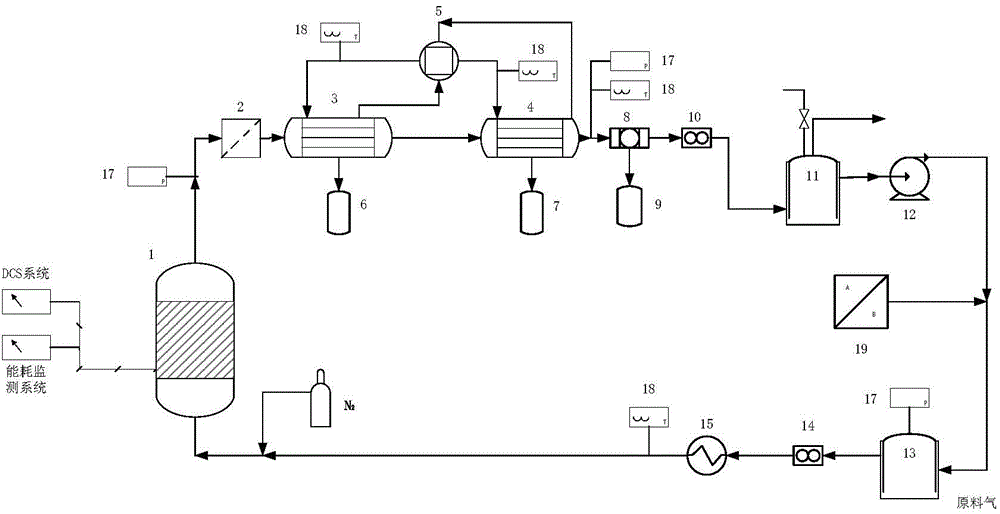

[0084] Carry out forced convection pyrolysis of carbonaceous substances and measurement of dust content

[0085] Such as Figure 4 As shown, block materials (10-50mm) with different particle sizes are put into the reactor 1, and then the nitrogen purge inlet at the bottom of the reactor 1 is injected with nitrogen to purge the system to achieve a hypoxic environment. The operating conditions such as the pyrolysis temperature, temperature rise program, and pyrolysis time of the reactor 1 are set through the DCS control system, and the reactor 1 is heated according to the temperature control program to perform pyrolysis reactions at different temperatures. All the gas (raw material gas) provided by the gas distribution system or the mixed gas drawn from the existing pyrolysis gas in the gas storage tank 11 and supplemented by the gas distribution system through the circulation pump 12 enters the gas mixing tank 13 to stabilize the pressure and the second flow rate After the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com