Circulating fluid bed waste incineration boiler with open-type furnace chamber

A circulating fluidized bed and open furnace technology, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of needing to shut down the furnace for cleaning, poor fluidization, and large slag discharge port area, so as to prevent coking or slag formation. The effect of slag, simple structure and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

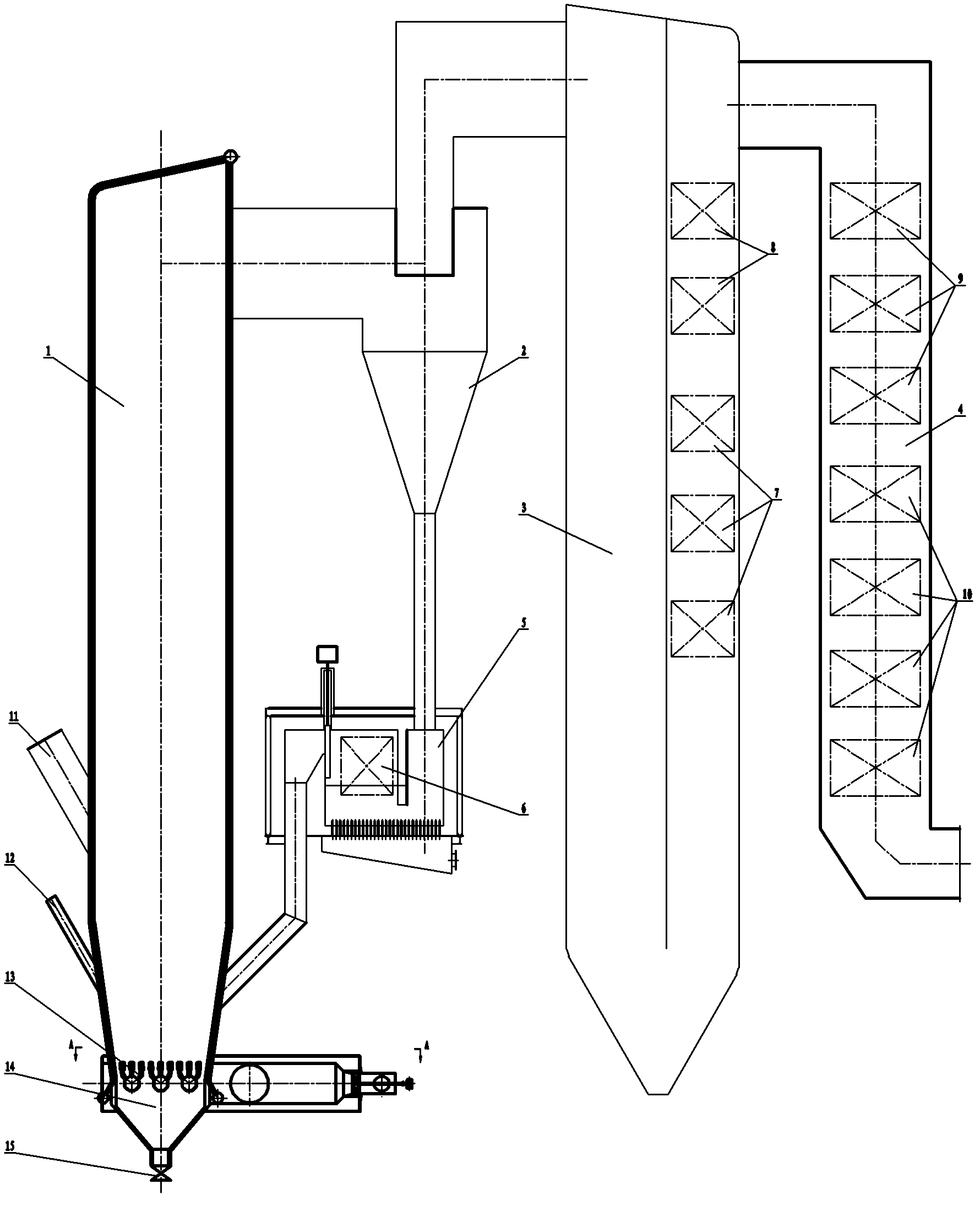

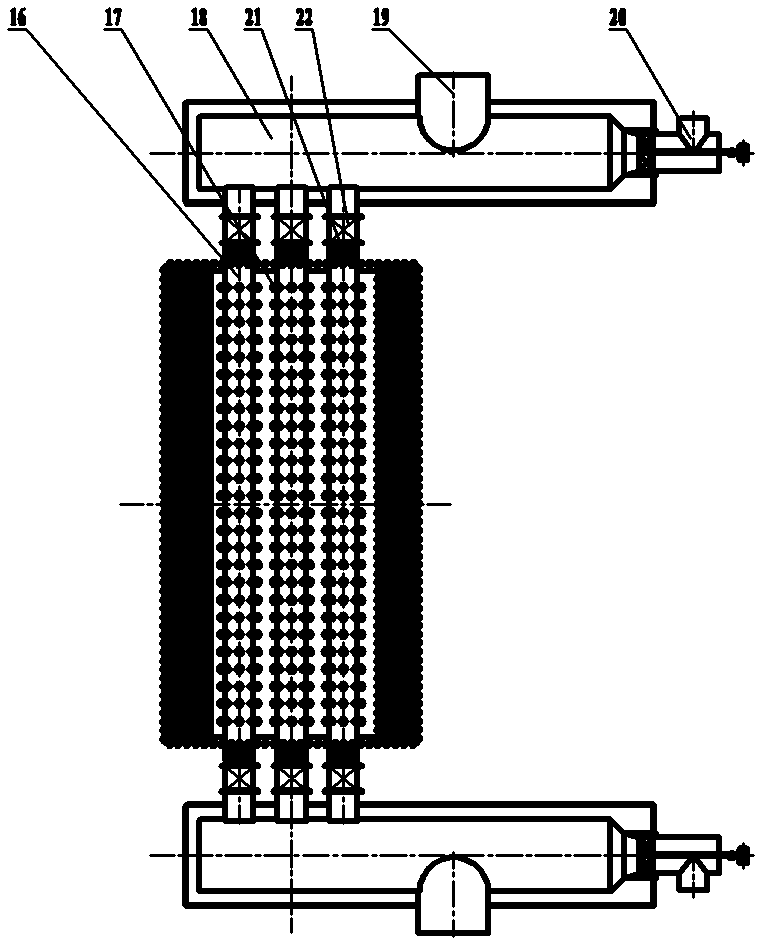

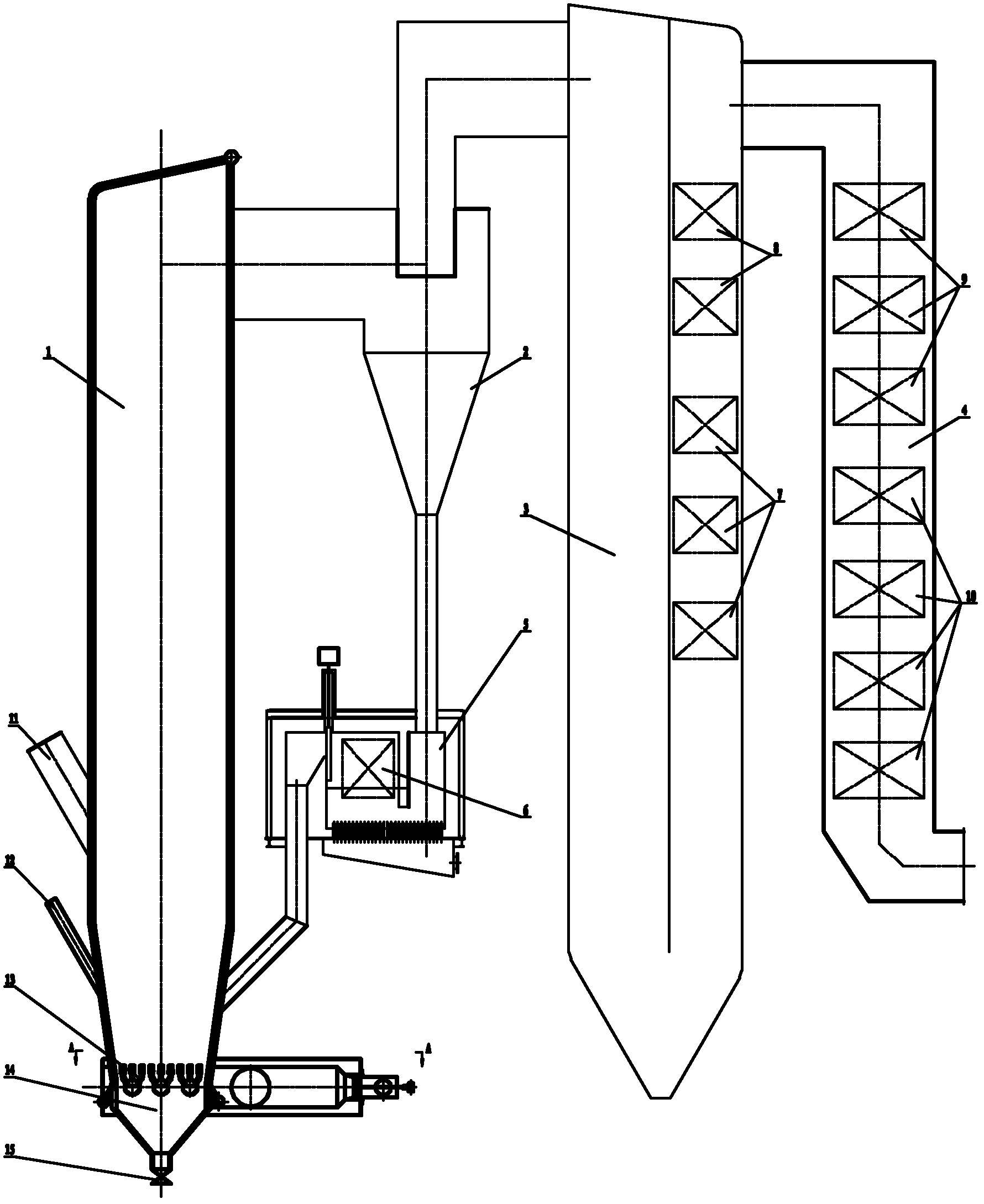

[0015] Its implementation will be further described below in conjunction with the accompanying drawings of the present invention:

[0016] Such as Figure 1 ~ Figure 2 As shown, it includes open furnace 1, cyclone separator 2, cooling chamber 3, tail convection flue 4, external heat exchanger 5, high temperature superheater 6, low temperature superheater 7, economizer 8, secondary air preheater Heater 9, primary air preheater 10, garbage feed port 11, auxiliary fuel feed port 12, open air distribution plate 13, ash hopper 14, ash valve 15, air distribution pipe 16, exhaust cap 17 , Ignition device 18, primary air inlet 19, ignition oil gun 20, expansion joint 21 and damper 22.

[0017] The present invention mainly consists of sequentially connected open furnace 1, cyclone separator 2, cooling chamber 3 and tail convection flue 4; the lower end of the cyclone separator 2 is connected to an external heat exchanger 5) the external heat exchanger 5 The other end is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com