Continuous hydrolysis kettle converted from furfural intermittent hydrolysis kettle

A technology for hydrolyzing kettle and furfural, which is applied in chemistry/physics/physicochemistry fixed reactors, organic chemistry, etc., and can solve problems such as energy waste, environmental pollution, and steam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

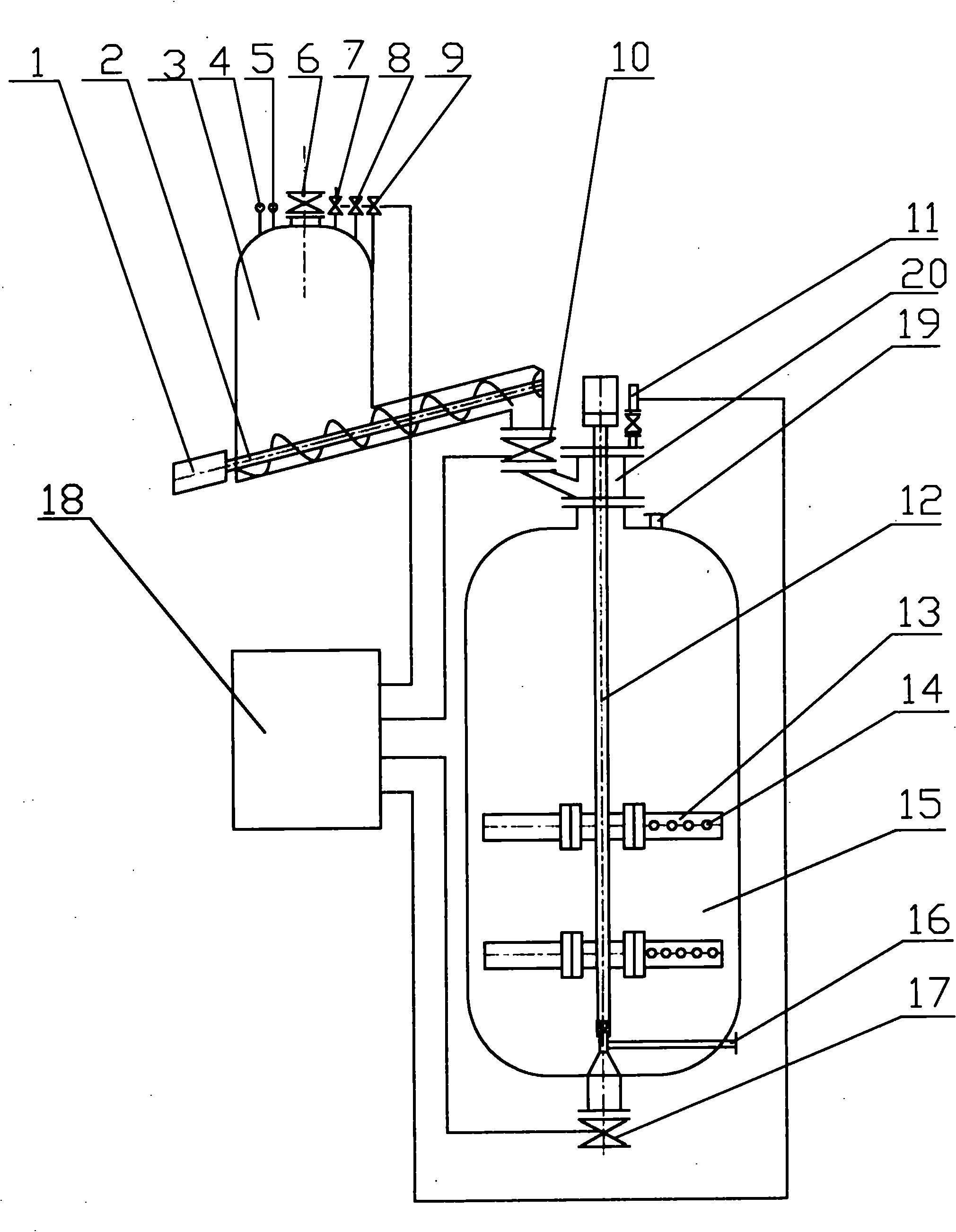

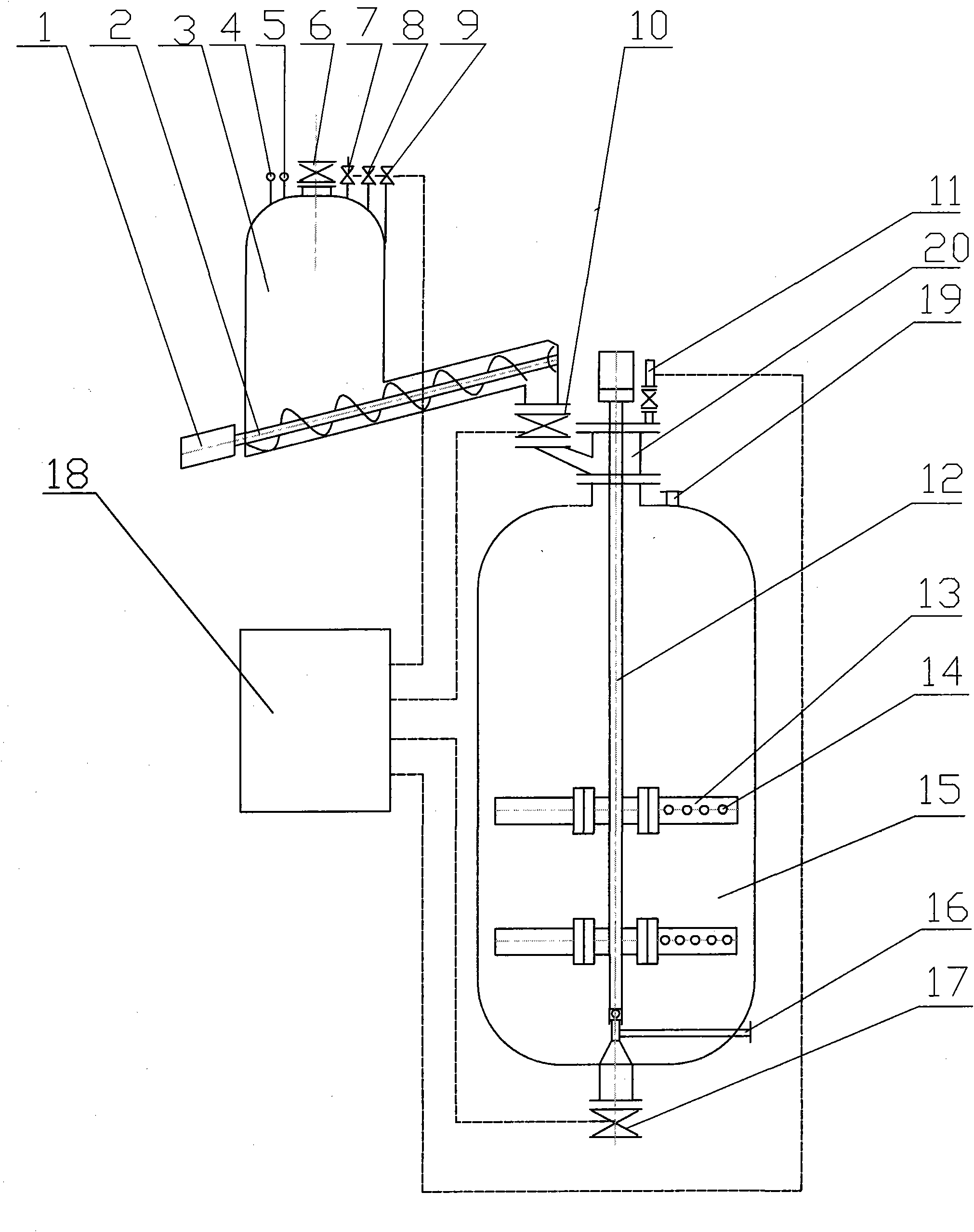

[0010] Such as figure 1 As shown, a section of neck 20 is connected on the manhole flange of furfural hydrolysis kettle 15, and a feeding hole is obliquely opened on neck 20, and the flange on the hole is connected with the discharge port valve 10 of screw conveyor 2, when valve 10 is opened , the hydrolysis kettle 15 is connected with the screw conveyor 2, the feed box 3 is integrated with the screw conveyor, and is a pressure vessel, the screw conveyor 2 is driven by the motor 1 to rotate, and the feed box 3 is provided with a feed inlet valve 6, Pressure gauge 5, vacuum pressure gauge 4, vacuum pipe valve 7, steam pipe valve 8, condensation pipe valve 9, a material level monitoring device 11 is provided on the hydrolysis kettle 15, and all valves, motors, and material level monitoring devices are controlled by a computer 18.

[0011] The stirring device of the hydrolysis kettle is provided with a central hollow main shaft 12, and the central hollow main shaft 12 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com