Rapid cooling device for chemical production

A rapid cooling and chemical production technology, applied in heat exchange equipment, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of unsatisfactory chemical production, uneven heat transfer of chemical products, and affecting the production quality of chemical products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

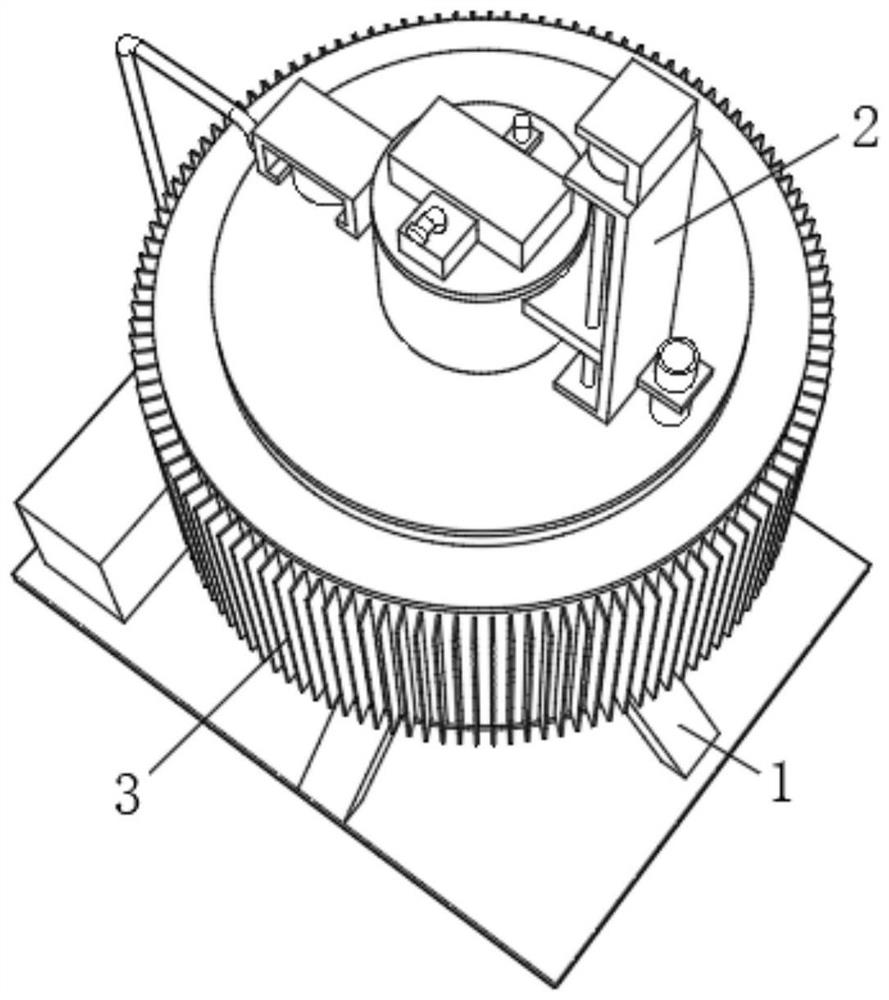

[0036] Such as Figure 1-10 As shown, the present invention provides a kind of rapid cooling device for chemical production, a material storage mechanism 1, a first cooling mechanism 2 and a second cooling mechanism 3 are fixed on the material storage mechanism 1, and the first cooling mechanism 2 is located at the front of the material storage mechanism 1. above;

[0037] The material storage mechanism 1 includes a material storage tank 4. A cover plate 5 is fixed on the top of the material storage tank 4. A first chute 6 is opened at the axis of the cover plate 5. A feed pipe 7 is fixed through the cover plate 5. The first slide Both the tank 6 and the feed pipe 7 are connected to the inside of the storage tank 4, and the bottom of the storage tank 4 is fixed with a discharge pipe 8, and the feed pipe 7 and the discharge pipe 8 are provided with a first valve 9, and the storage The bottom of the tank 4 is fixed with four support plates 10 distributed in a circular array, an...

Embodiment 2

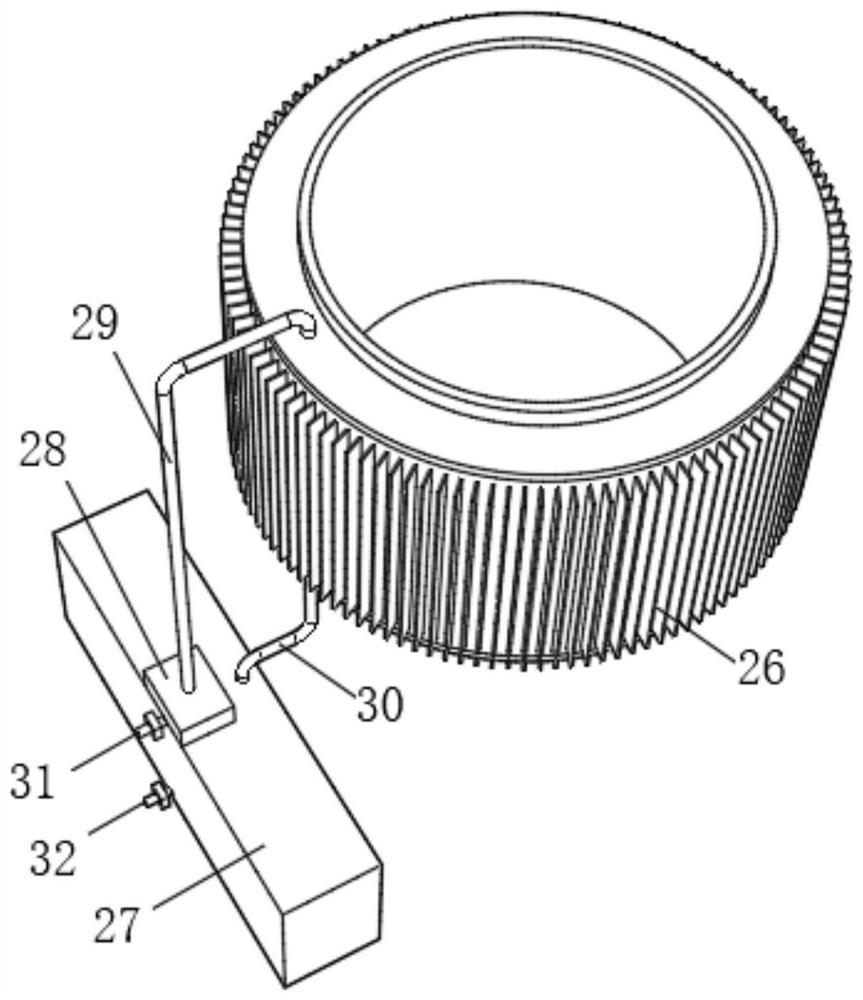

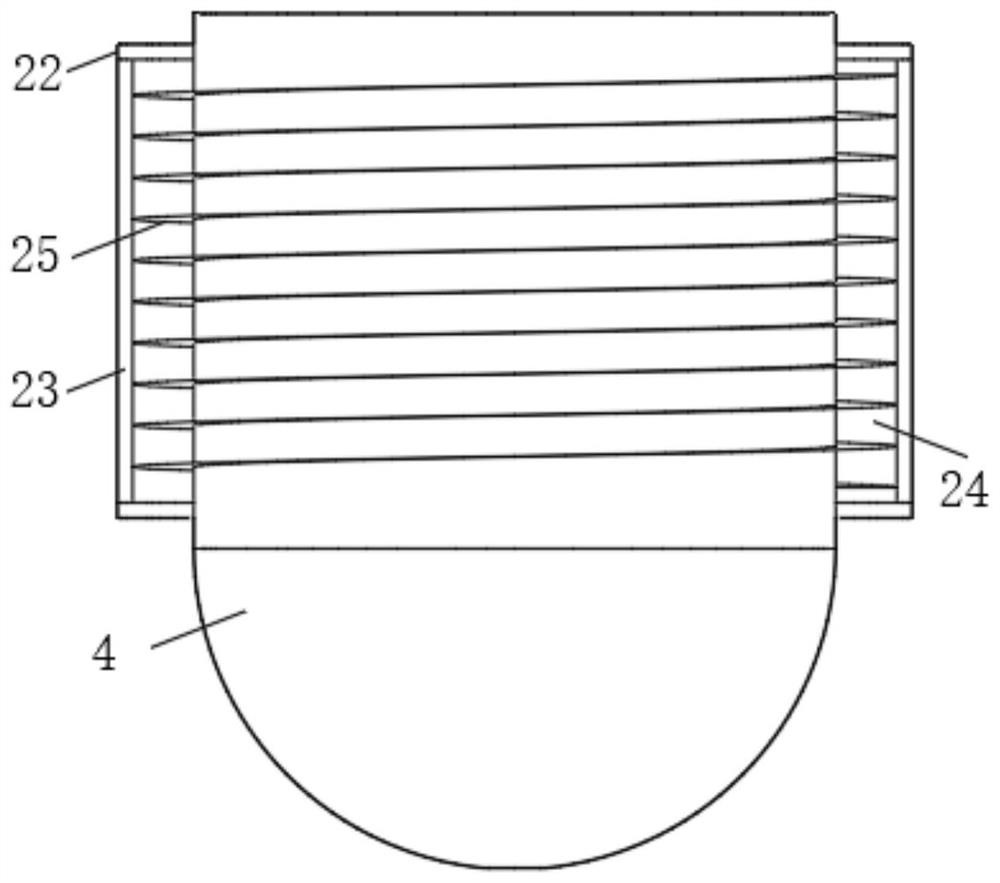

[0052] The applicant found in use that according to the operation process of Example 1, the cooling effect of the chemicals located above the fixed plate 15 is better, but the stirring effect of the chemicals located below the fixed plate 15 is relatively poor. For further cooling of chemical products, the applicant is provided with a number of baffles 48 on the inner wall of the storage tank 4 under the fixed plate 15. The baffles 48 are located opposite each other and staggered up and down. The baffles 48 are provided with cavities and It communicates with the cavity 24. When the operator controls the water pump 28 to input the water in the water tank 27 into the cavity 24, since the cavity in the baffle 48 communicates with the cavity 24, the water will flow into the baffle from the cavity 24 In the cavity in 48, the cooling area to the chemical products below the fixed plate 15 is increased, and the chemical products below the storage tank 4 are further cooled. Under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com