Cone gas distributor for fluidized bed

A gas distributor and fluidized bed technology, which is applied in the field of fluidized bed reaction devices, can solve the problems of large pressure drop of the sieve plate gas distributor, inconvenient maintenance and maintenance, easy blockage of impurities, etc., and achieves reliable guarantee of continuous and stable operation, Easy to disassemble and maintain, to avoid the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

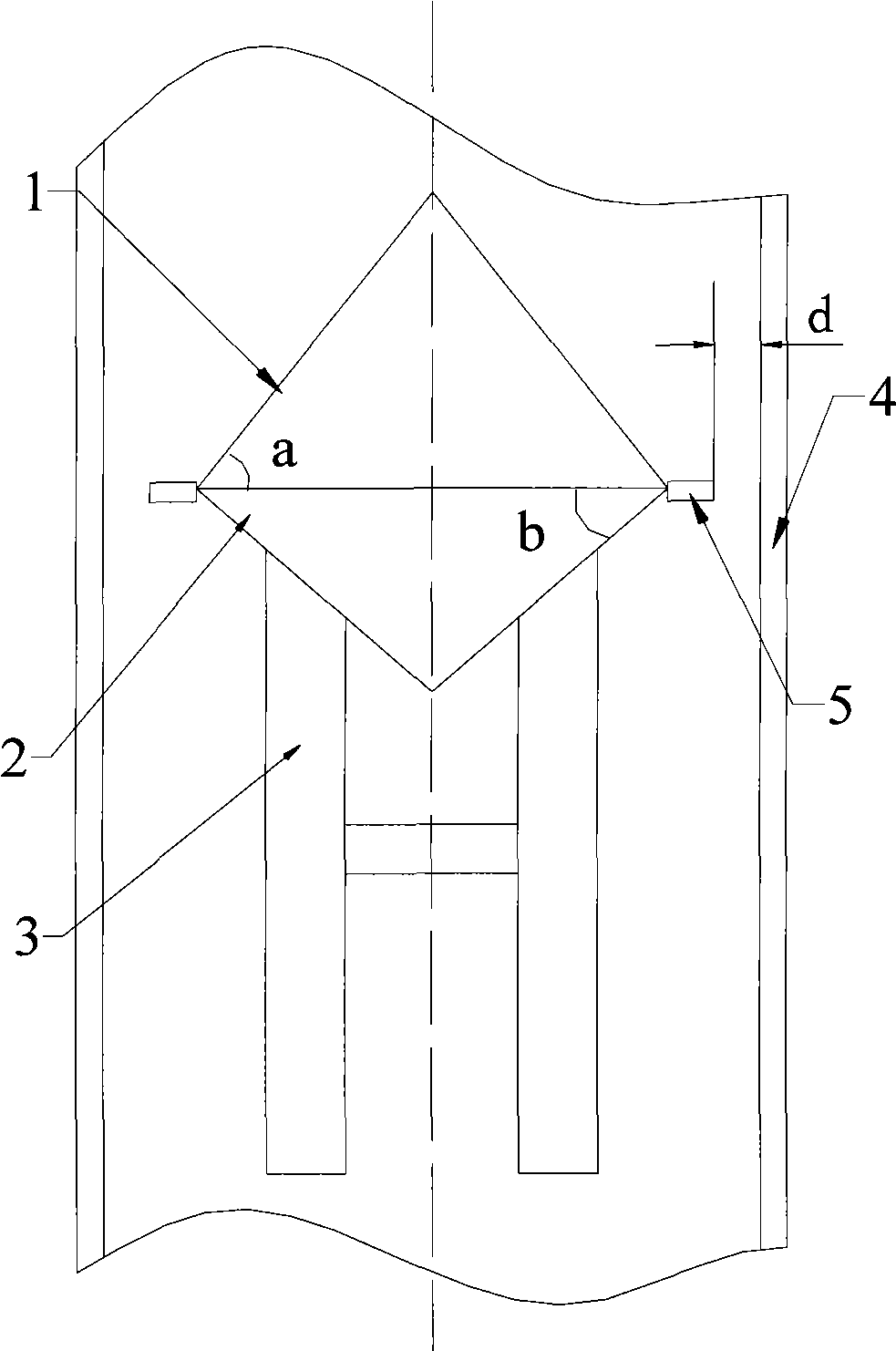

[0013] A cone-shaped gas distributor for a fluidized bed, which is arranged in a gas-collecting chamber 4 and includes an upper cone 1, a lower cone 2, a support 3, and a lower cone 2 is arranged upside down on the support 3, and on the lower cone 2 An upper cone 1 is provided, and the bottom surface of the upper cone 1 is opposite to the bottom surface of the lower cone 2. The upper cone 1 and the lower cone 2 have the same bottom diameter, and the bottom diameter is smaller than the inner diameter of the gas collection chamber 4, so that the upper cone 1 and the bottom surface of the lower cone 2 form a uniform annular gap with the inner wall of the gas collection chamber 4, and the annular gap is between 2mm and 20mm, that is to say, the diameter of the bottom surface of the upper cone 1 is smaller than that of the gas collection chamber. The inner diameter of the chamber 4 is 4mm-40mm. Since the gas is distributed in the form of an annular gap structure, the pore size is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com