Pre-cleaning chambers and semiconductor processing equipment

A pre-cleaning and chamber technology, applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as uneven gas distribution, different path lengths, process gas waste, etc., to improve the uniformity of gas distribution , Shorten time and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the technical solutions of the present invention, the pre-cleaning chamber and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

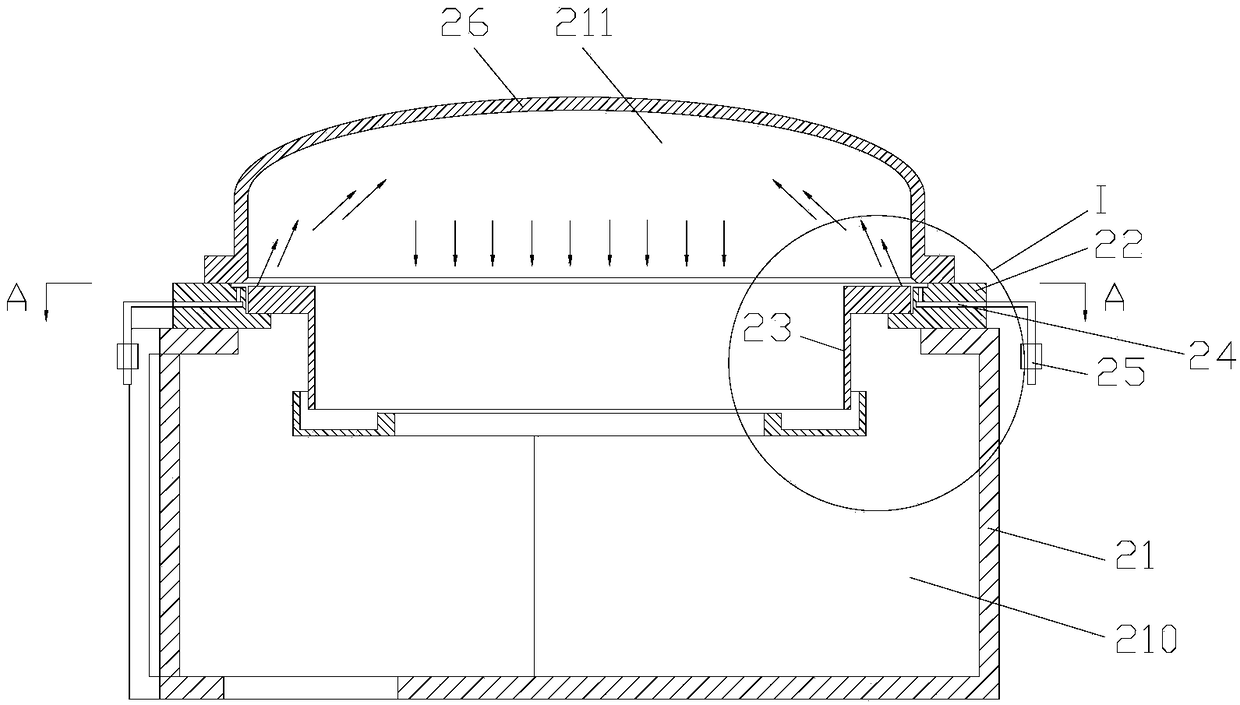

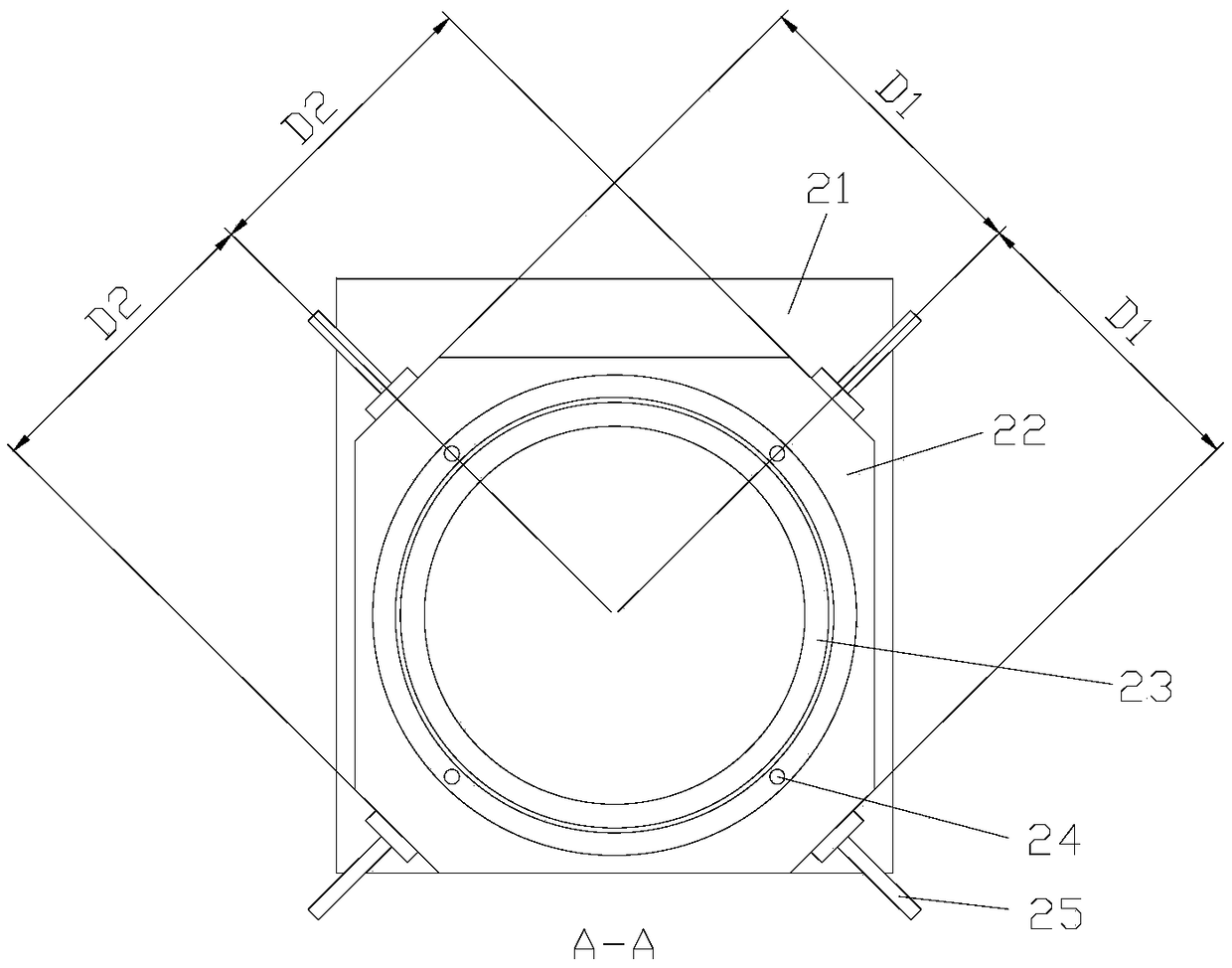

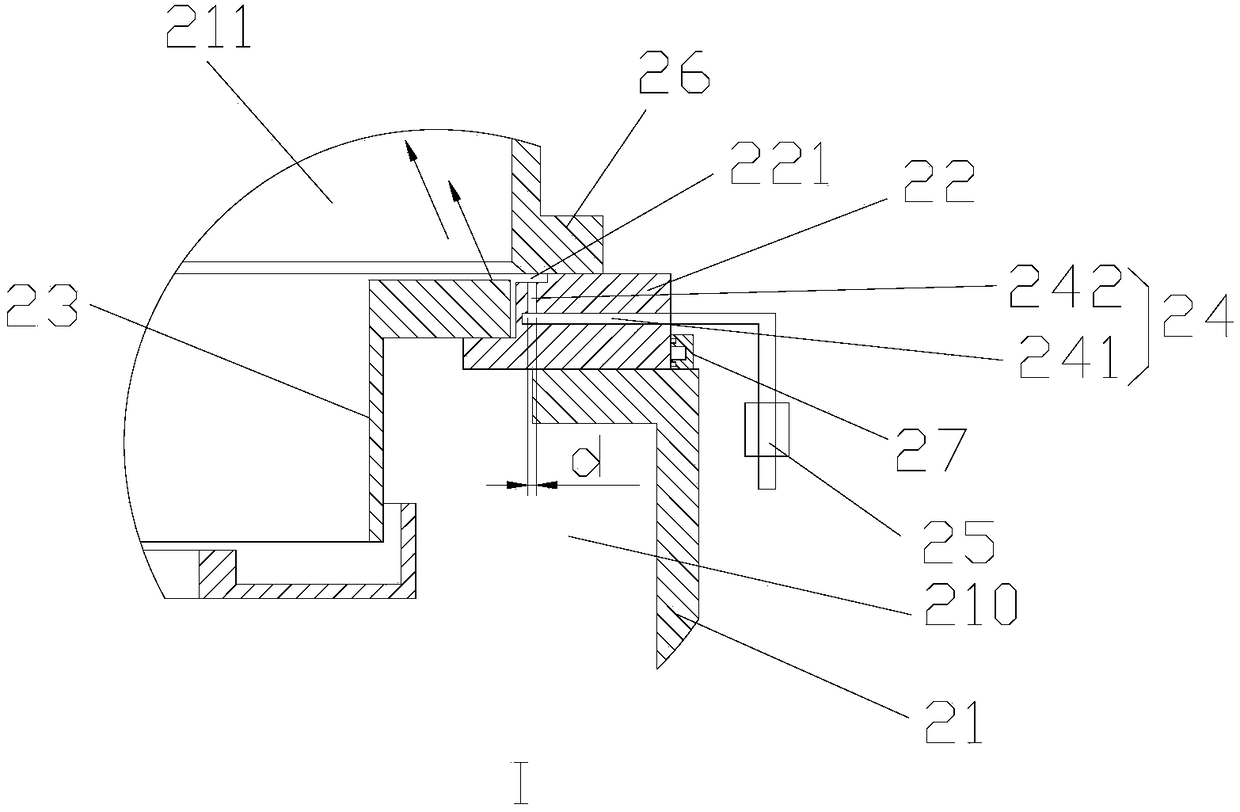

[0027] figure 1 A cross-sectional view of a pre-cleaning chamber provided for an embodiment of the present invention. figure 2 for figure 1 A top view along the line A-A. image 3 for figure 1 Zoom-in view of the middle I region. Please also refer to Figure 1-3 , the pre-cleaning chamber is formed by a chamber body 21 and a medium window 26 arranged on the top of the chamber body 21 . The dielectric window 26 is an arched top cover made of insulating material (such as ceramic or quartz). Moreover, a process component 23 is arranged around the pre-cleaning chamber, and the structure of the process component 23 is as follows: figure 1 As shown, it is a ring structure, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com