Dust-resistant solenoid valve component

A solenoid valve assembly, anti-dust technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problem of long intake and exhaust paths of solenoid valves, small intake and exhaust volumes of solenoid valves, and compressed gas quality. problems such as decline, to achieve the effect of long order period, increase in air intake and exhaust volume, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

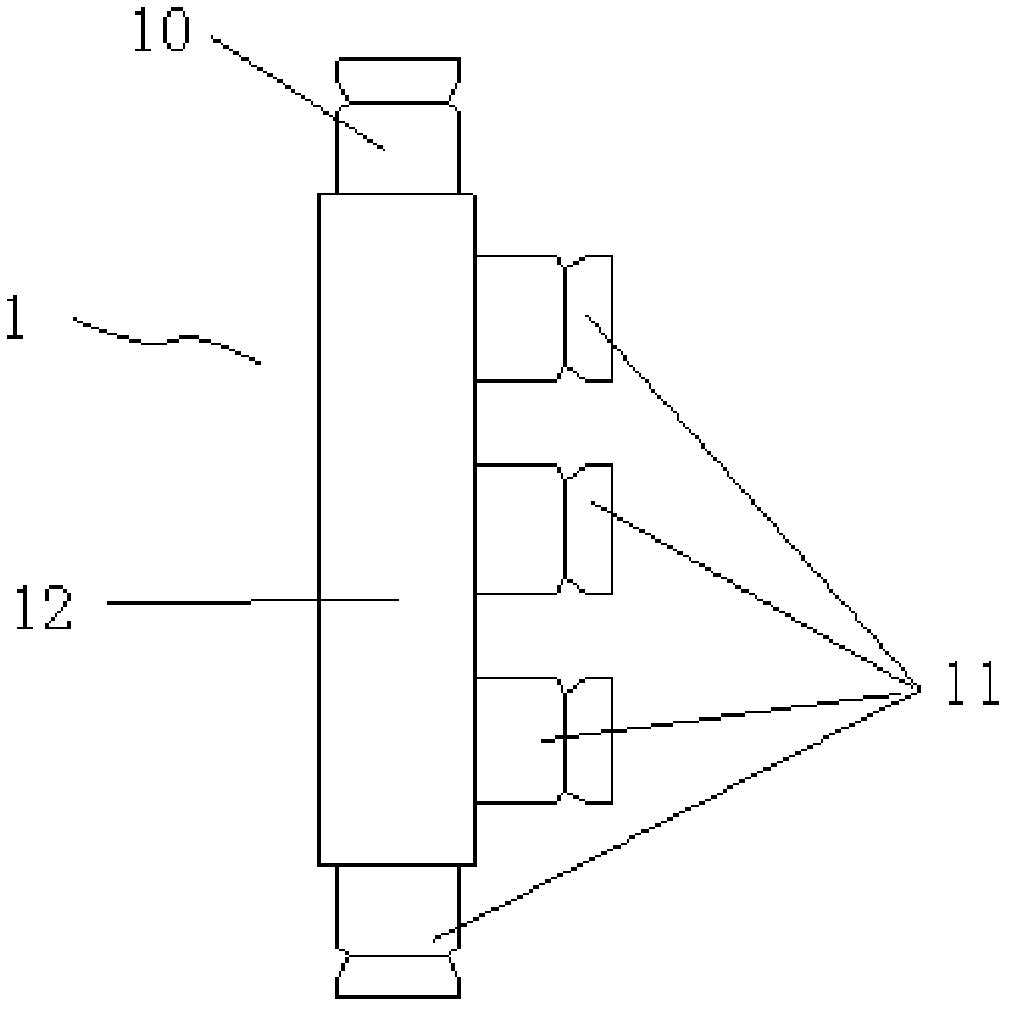

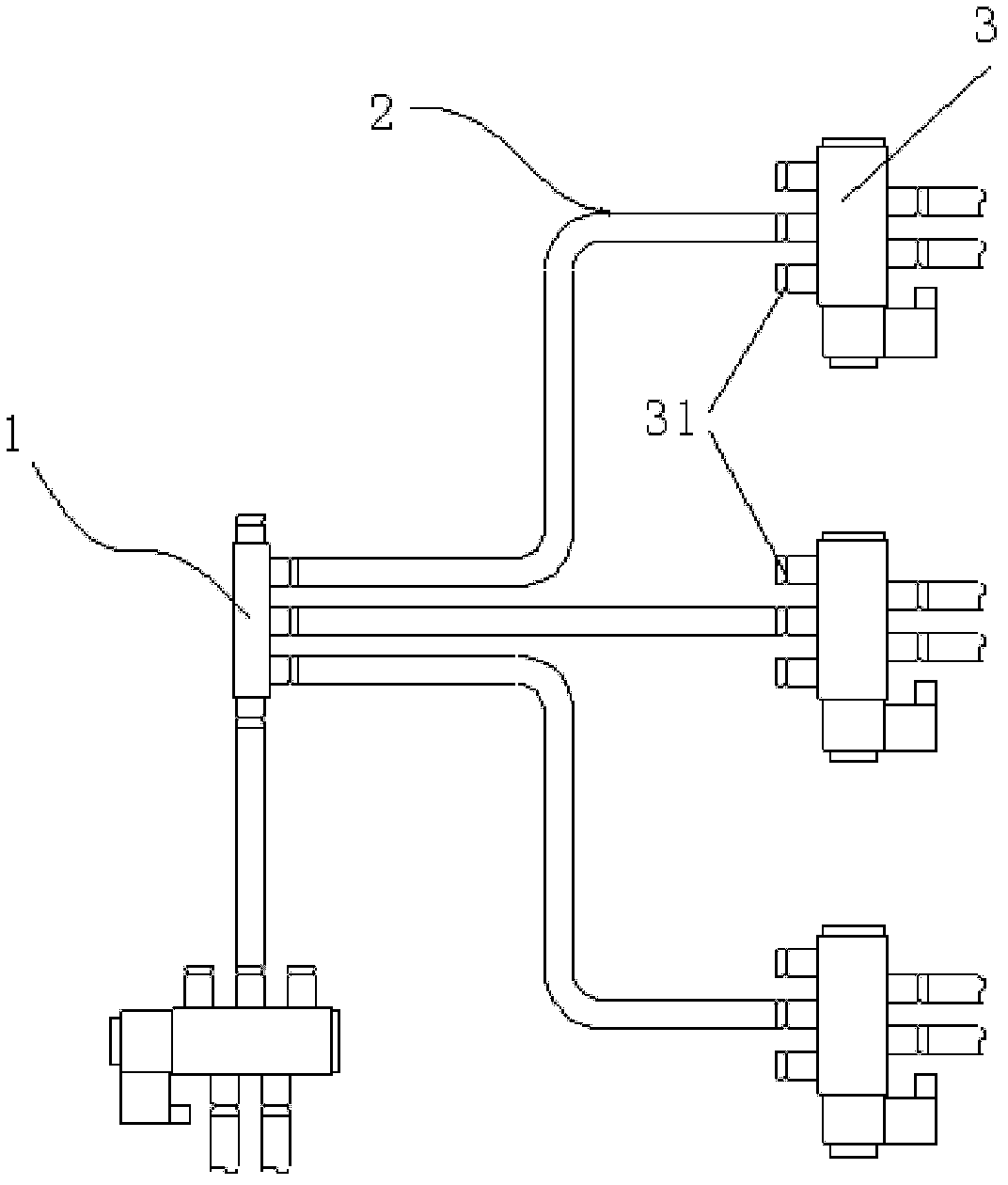

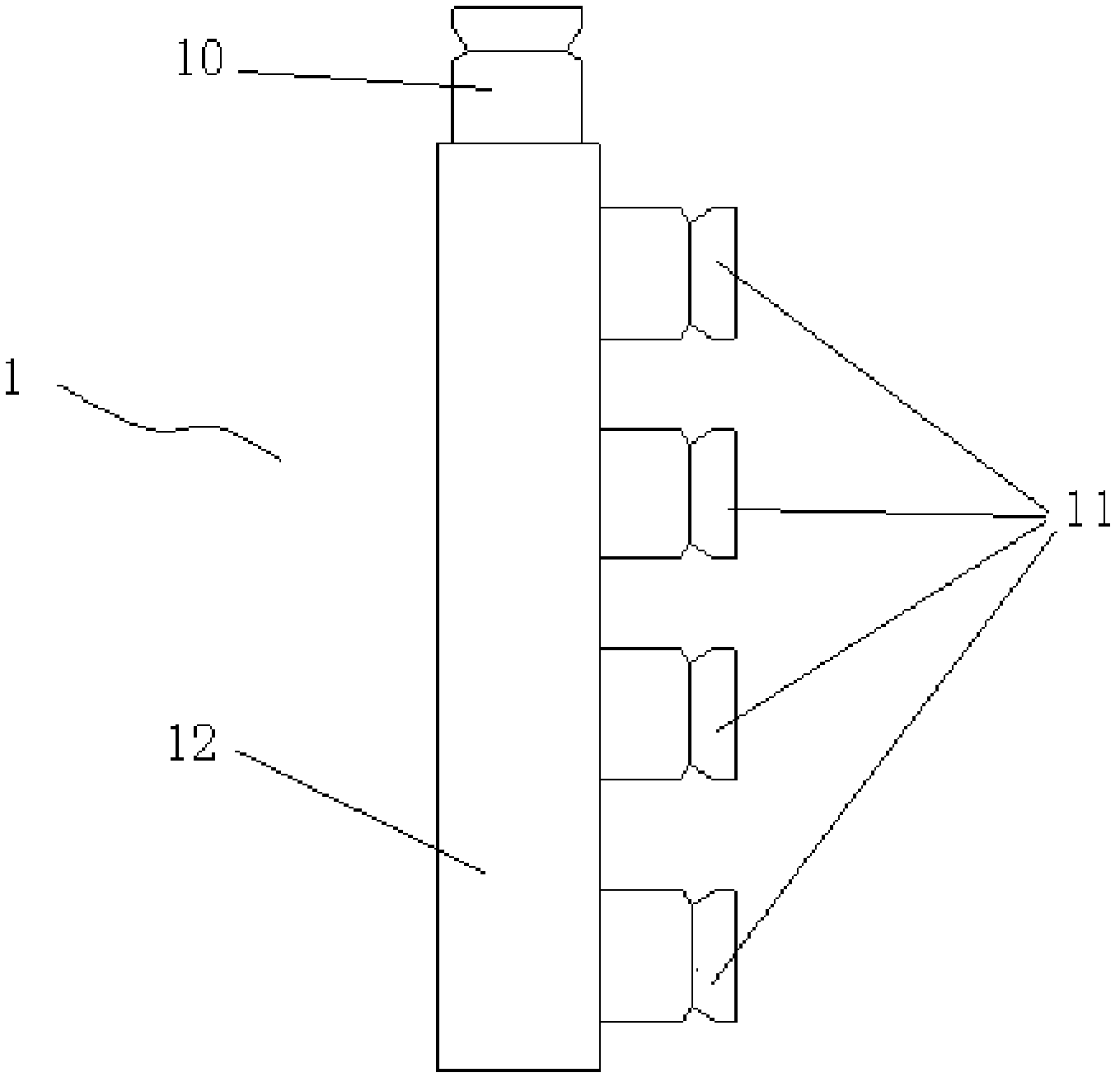

[0015] Reference attached figure 2 , The anti-dust solenoid valve assembly of the present invention includes 4 solenoid valves 3, and the domestic solenoid valve with an outer diameter of φ12 of the optional piping is selected, and the solenoid valve 3 is provided with an air inlet. An air source distributor 1 is also provided, which includes an air source distributor body 12 with an inner cavity and a total air inlet 10, and 4 branch air ports 11 and 4 branch air ports are also arranged on the air source distributor body. The gas port, the total gas inlet and the inner cavity are in gas communication with each other. An embodiment such as image 3 As shown, the general air inlet 10 is arranged at one end of the main body 12 of the air source distributor, and the other end of the main body 12 of the air source distributor is sealed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com