Gas uniform-distribution type premixing burner

A premixed combustion and uniform distribution technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as uneven temperature distribution on the combustion surface and poor gas mixing, so as to improve the uniformity of gas distribution, The effect of enhancing the uniformity of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

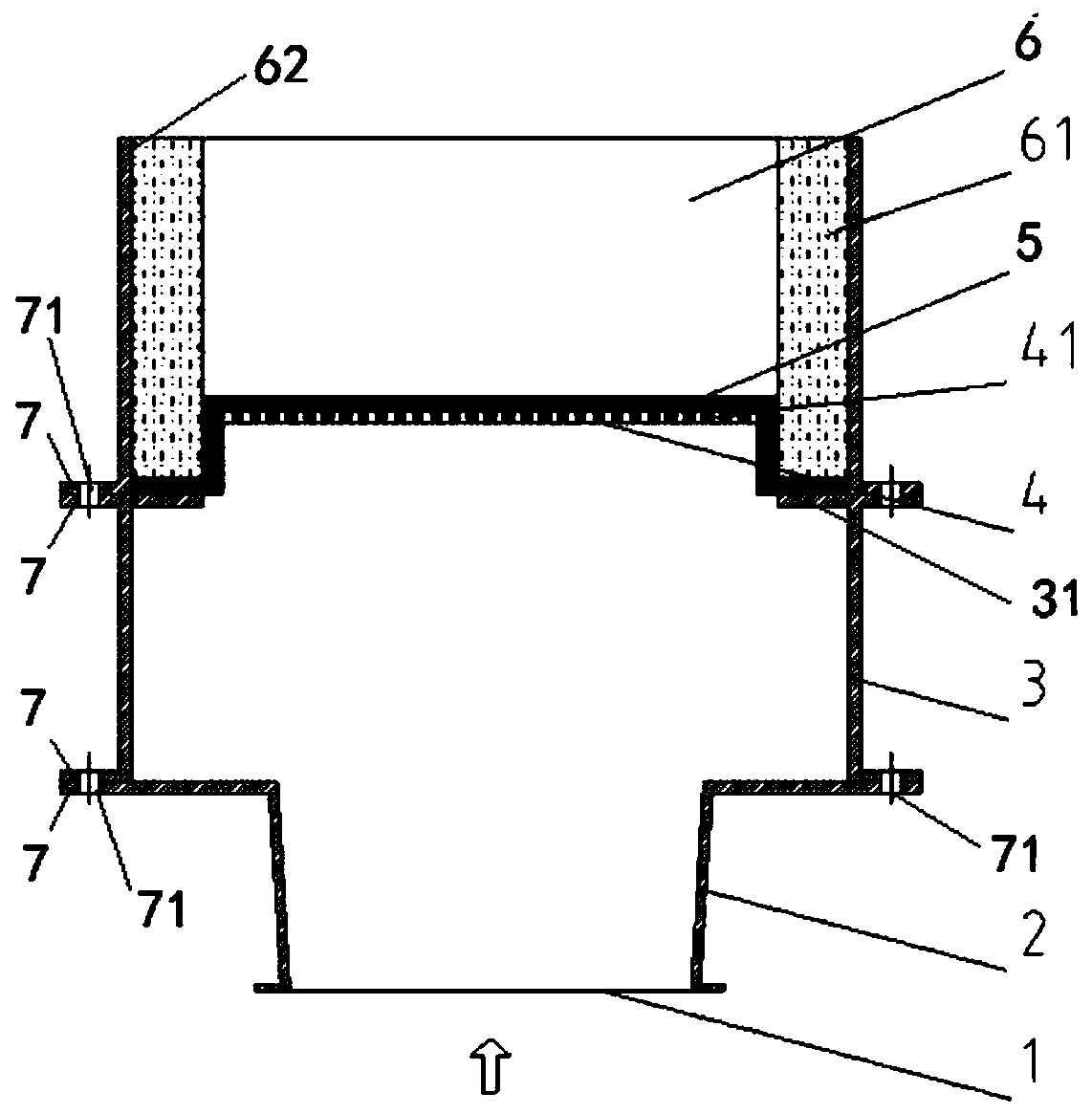

[0025] Depend on figure 1 As shown, the present invention includes a premix gas inlet, a diffusion chamber, a mixing chamber, a gas equalization plate, a metal fiber surface, and a flue.

[0026] A gas uniform distribution type premix burner, including a diffusion chamber with a premixed gas inlet, a mixing chamber, a gas uniform plate, a metal fiber surface and a flue arranged in sequence along the gas direction and fixedly connected as a whole; The inlet of the premixed gas is arranged at the gas inlet end below the diffusion chamber; the outlet of the diffusion chamber is connected to the mixing chamber; the gas uniform plate is located between the mixing chamber and the surface of the metal fiber; the flue is located outside the surface of the metal fiber.

[0027] Such as figure 2 As shown, the shape of the diffusion chamber is a truncated cone with a cone angle of 15°.

[0028] The shape of the mixing chamber is cylindrical, matching with the truncated cone of the dif...

Embodiment 2

[0036] The difference from Example 1 is:

[0037] Such as image 3 As shown, the shape of the diffusion chamber is a truncated pyramid with a cone angle of 21°.

[0038] The shape of the mixing chamber is a quadrangular prism, matching with the truncated quadrangular pyramid of the diffusion chamber.

[0039] The cross-sectional area of the mixing chamber is 1.5 times the cross-sectional area of the outlet of the diffusion chamber.

[0040] The arrangement of the through pores is a regular triangle or a regular quadrilateral, the center distance is 3 mm, and the hole diameter is 2 mm.

[0041] All the other contents are the same as in Example 1.

[0042] After the fuel gas and air are mixed, they enter the diffusion chamber from the premixed gas inlet. The cone angle of the diffusion chamber is 21°. The specific cone angle can separate the flow boundary layer, thereby avoiding the large velocity gradient of the fluid on the axial cross section. Make the fluid velocity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com