Manufacturing process of light prefabricated assembly type external wallboard

A technology of prefabricated assembly and manufacturing technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of roof panel leakage, non-conformity, and non-matching, etc., to improve the level of industrialization and standardization, the structure is firm and reliable, and the construction is improved. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0025] A manufacturing process of a light-weight prefabricated exterior wall panel, comprising the following steps:

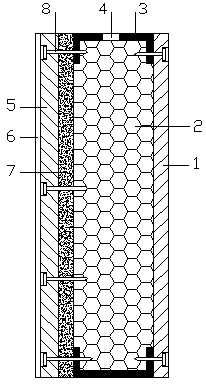

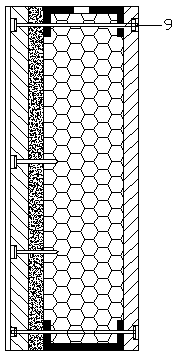

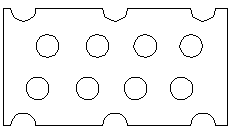

[0026] (1) Make the outer board 5, the outer base board 7 and the inner base board 1, the outer board and the inner base board are autoclaved aerated concrete boards, the outer base board is a calcium silicate board or a fiber cement board, and the outer base board A number of through holes are opened on the board, and the pouring insulation material can not only bond the outer base board and the inner base board, but also bond the outer board through the through holes on the outer base board, so that the entire wall board forms a whole, ensuring High structural strength.

[0027] (2) Use lightweight profiles to make a frame-type keel frame 3, and open a pouring hole 4 on one of the side walls of the keel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com