Stator permanent magnet type field modulation motor

A permanent magnet type, stator technology, applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of low mechanical reliability of the rotor, poor heat dissipation of the permanent magnet, etc., and achieve Easy to modularize and offline, convenient mechanical assembly, and high mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

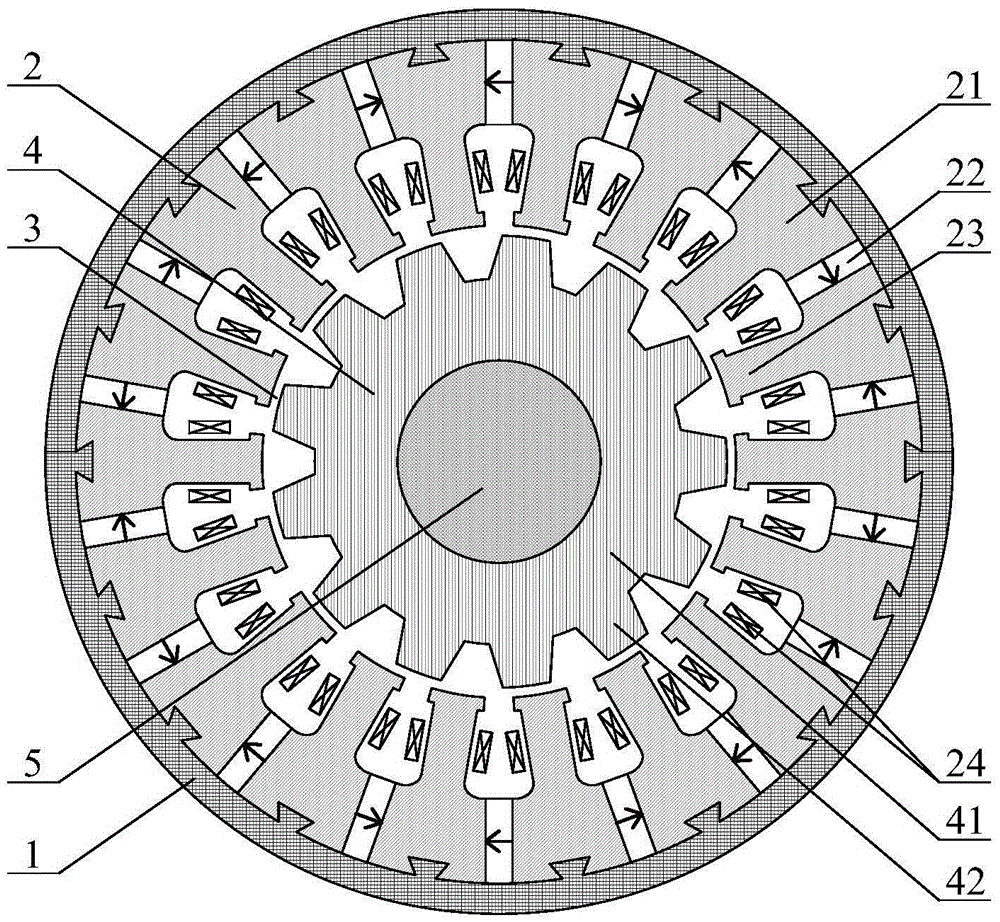

[0019] The invention provides a stator permanent magnet type field modulation motor, the motor includes a coaxial casing 1, a stator 2, an air gap 3, a rotor 4 and a rotating shaft 5 arranged from outside to inside, and the stator 2 is fixed on the casing through a dovetail groove 1, an air gap 3 is provided between the stator 2 and the rotor 4, and the rotor 4 is fixed on the outside of the rotating shaft 5; Permanent magnets 22, stator teeth 23 protruding from the inner circumference of the stator core 21, multi-phase symmetrical armature windings 24 embedded between adjacent stator teeth 23; the rotor 4 includes an annular rotor core 41 coaxial with the stator 2 , a number of salient rotor poles 42 protruding from the periphery of the rotor core 41; the housing 1 is a non-magnetic ring-shaped part for fixing the stator 2; the number N of the stator teeth 23 s , the pole pair number p of the armature winding 24 w , the number N of rotor salient poles 42 r Satisfy the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com