Pile foundation full-casing full-rotation construction process under complex geological conditions

A technology with complex geological conditions and construction technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as easy collapse, lack of protection, material waste, etc., to achieve a firm and reliable structure, high strength and rigidity , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

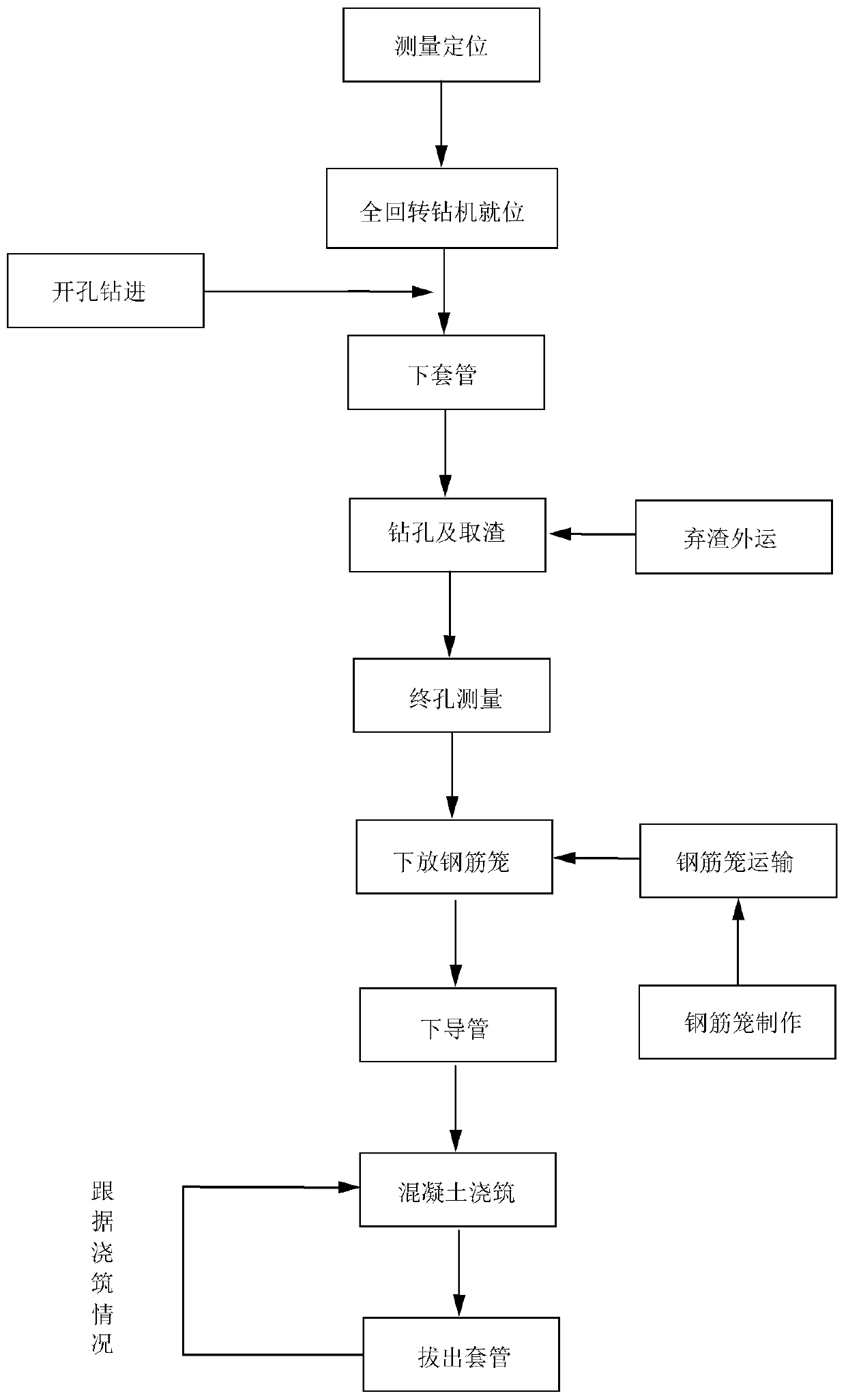

[0032] refer to figure 1 , the present invention provides a kind of pile foundation full-casing full-rotation construction technology under complex geological conditions, including the following steps:

[0033] S1. Preparation before drilling:

[0034] (1) No less than 3 control piles and benchmarking points shall be set near the construction area, and the setting position shall not be affected by the pile construction as a principle;

[0035] (2) After the construction scope is determined, it is necessary to use machinery to level the site to facilitate the construction of full-casing and full-rotary drilling rigs. In addition, there must be a site of no less than 200m2 as a casing yard;

[0036] Among them, the construction of the full-casing full-rotary drilling rig is easy to cause the soft ground with insufficient strength to sink due to the weight of the main engine and the counterweight, causing the casing to tilt and unable to work; to solve this problem, pouring conc...

Embodiment 2

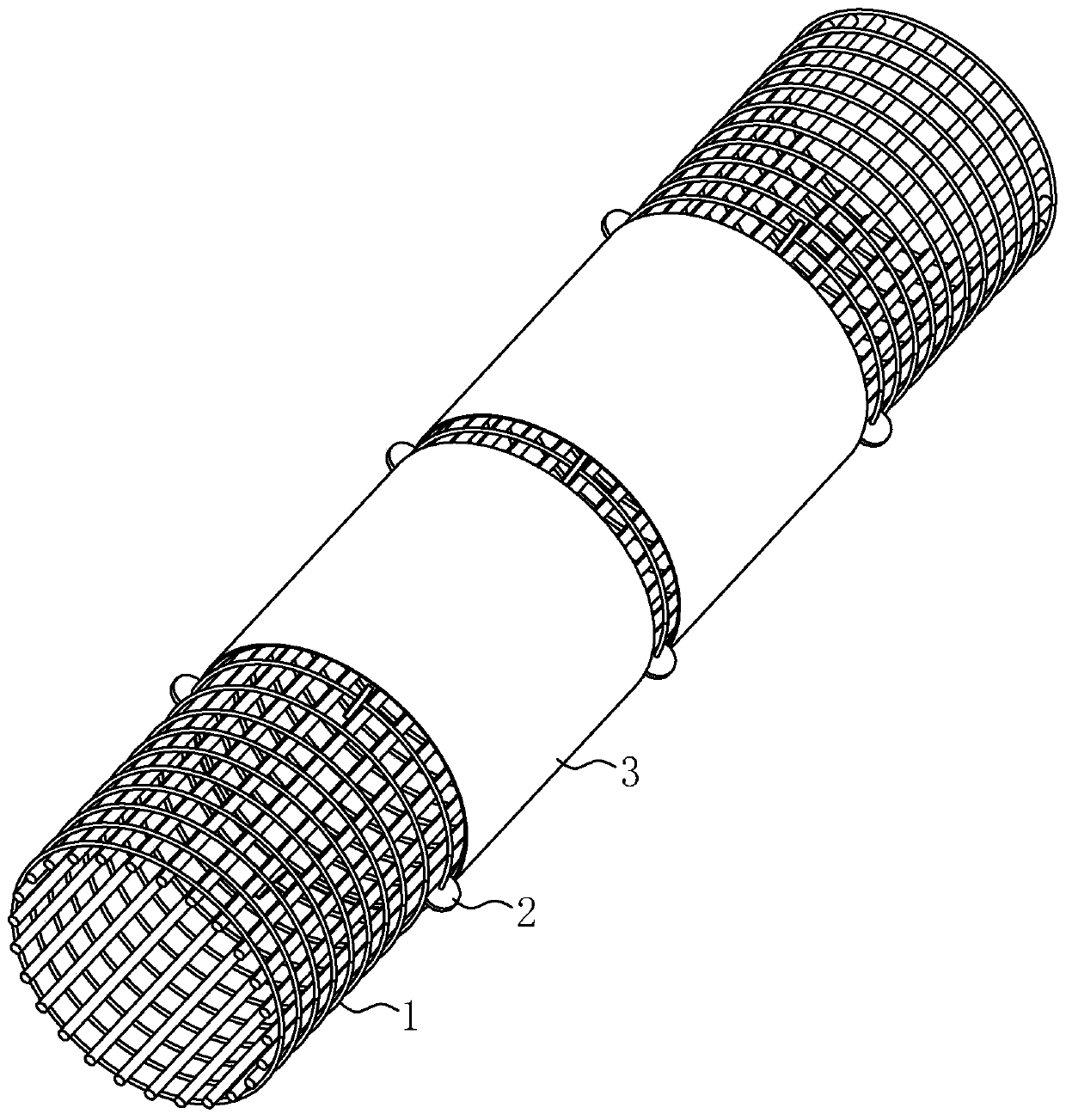

[0058] The difference from the first embodiment is that a steel bar ring for controlling the thickness of the steel bar protective layer is arranged symmetrically on the outside of the steel bar cage 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com