Ceramic halogen-free low-smoke fire-resistant cable

A fire-resistant cable and ceramic technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of inconvenient operation, single function, and increased equipment cost, and achieve the effects of shortened installation length, firm structure, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

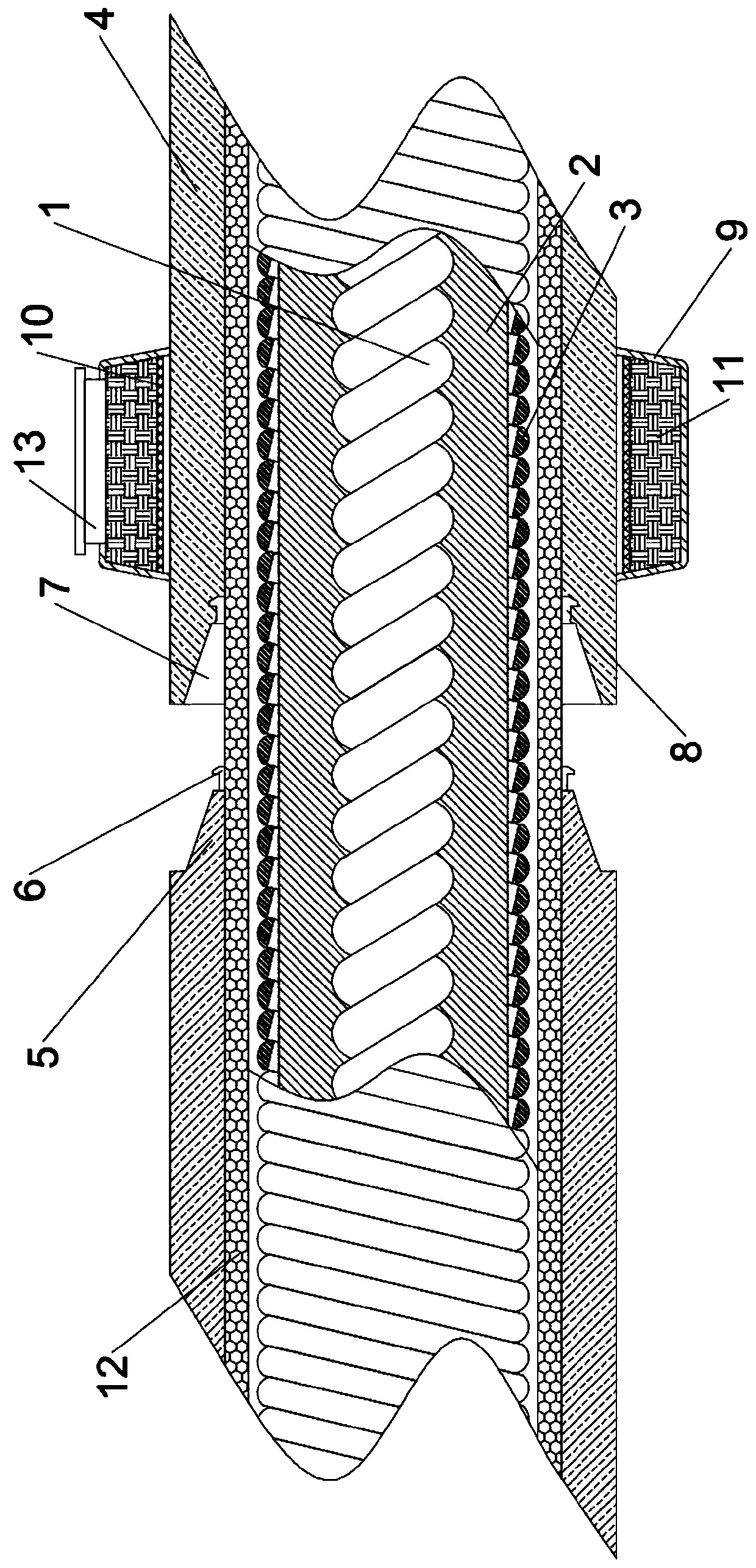

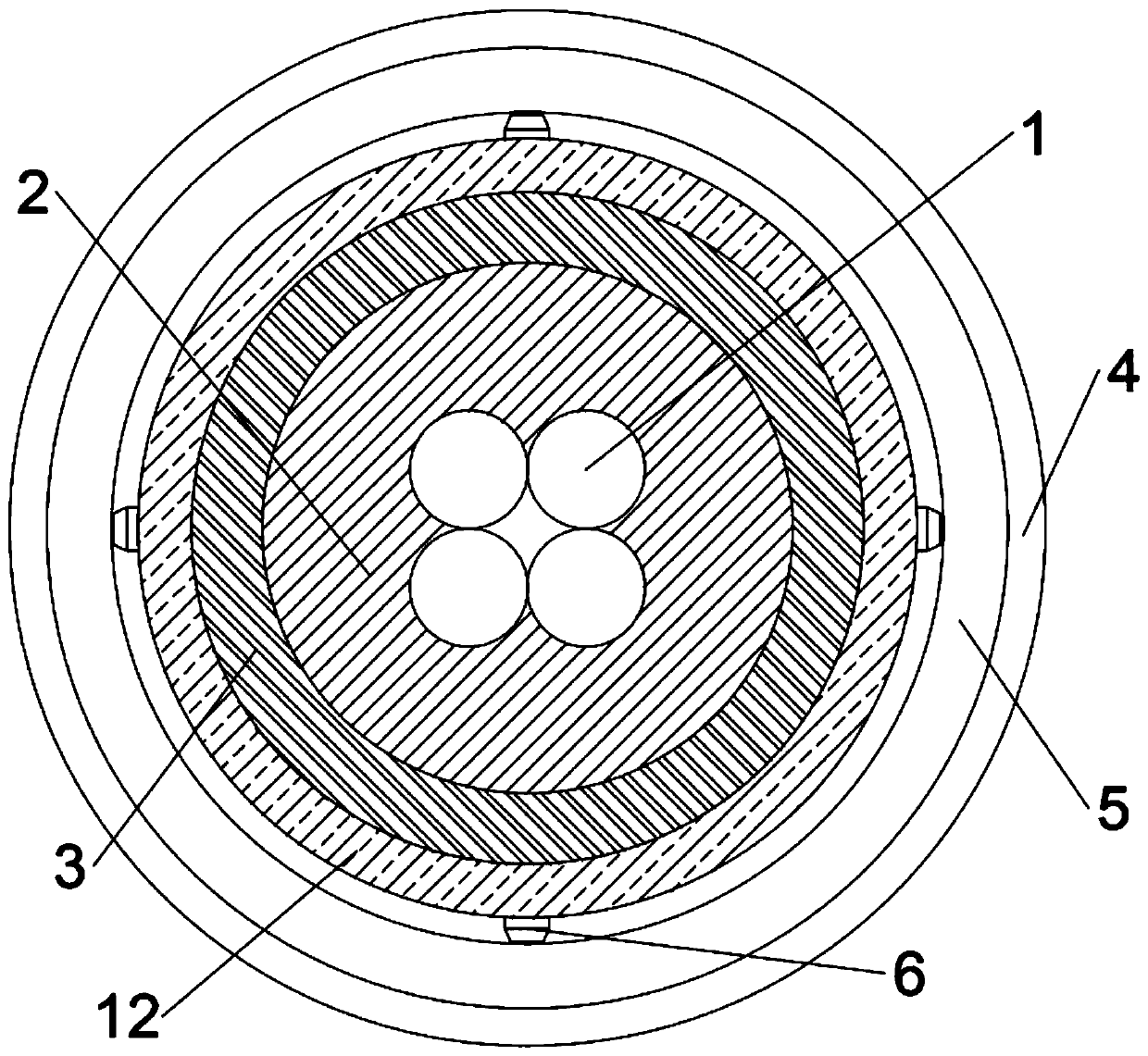

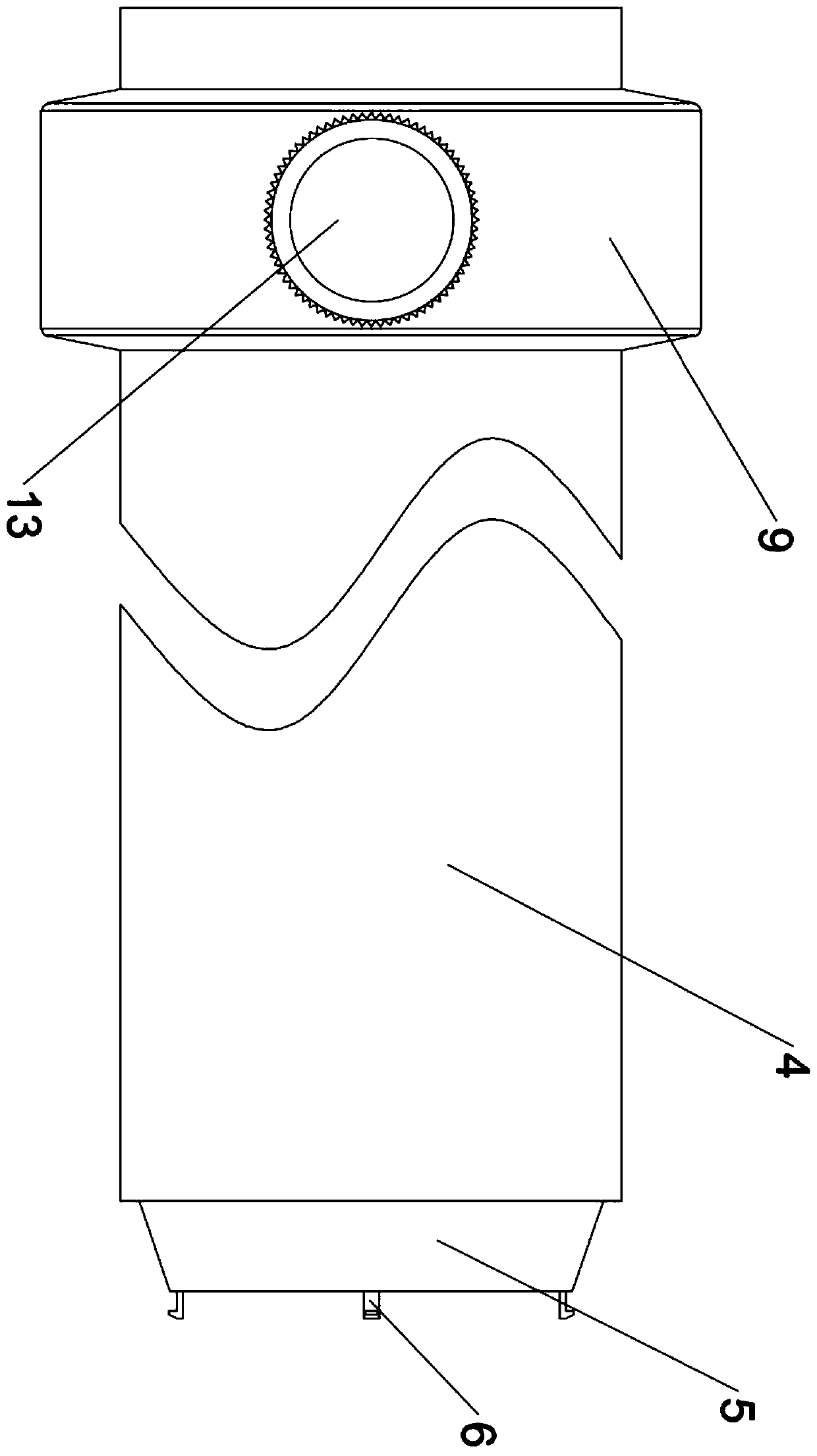

[0030] Embodiment: according to specification Figure 1-3 It can be seen that this case is a ceramic halogen-free low-smoke fire-resistant cable and its installation method, which mainly includes cable 1, insulating layer 2, insulating layer 3, and outer sheath 4. The above single cables 1 are twisted to make the cables 1 more flexible and integral. The insulating layer 2 containing low-smoke fire-resistant TPE rubber is extruded onto the cables 1 through an extruder, and the cables 1 are processed. Insulation protection, and through the metal insulation layer 3 armored on the insulation layer 2, the structural strength is increased, and the internal parts are protected, and the interior is physically protected by the outer sheath 4 made of ceramic powder, and it is fireproof function, and the outer protective tubes are connected end to end through the connection and fastening mechanism between several outer protective layers 4, through the inner slope structure 5 at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com