Reinforcement skeleton cage for concrete prefabricated pile

A technology of prefabricated concrete piles and reinforced skeleton, applied in sheet pile wall, construction, infrastructure engineering, etc. Tensile strength and impact resistance, easy installation and removal, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

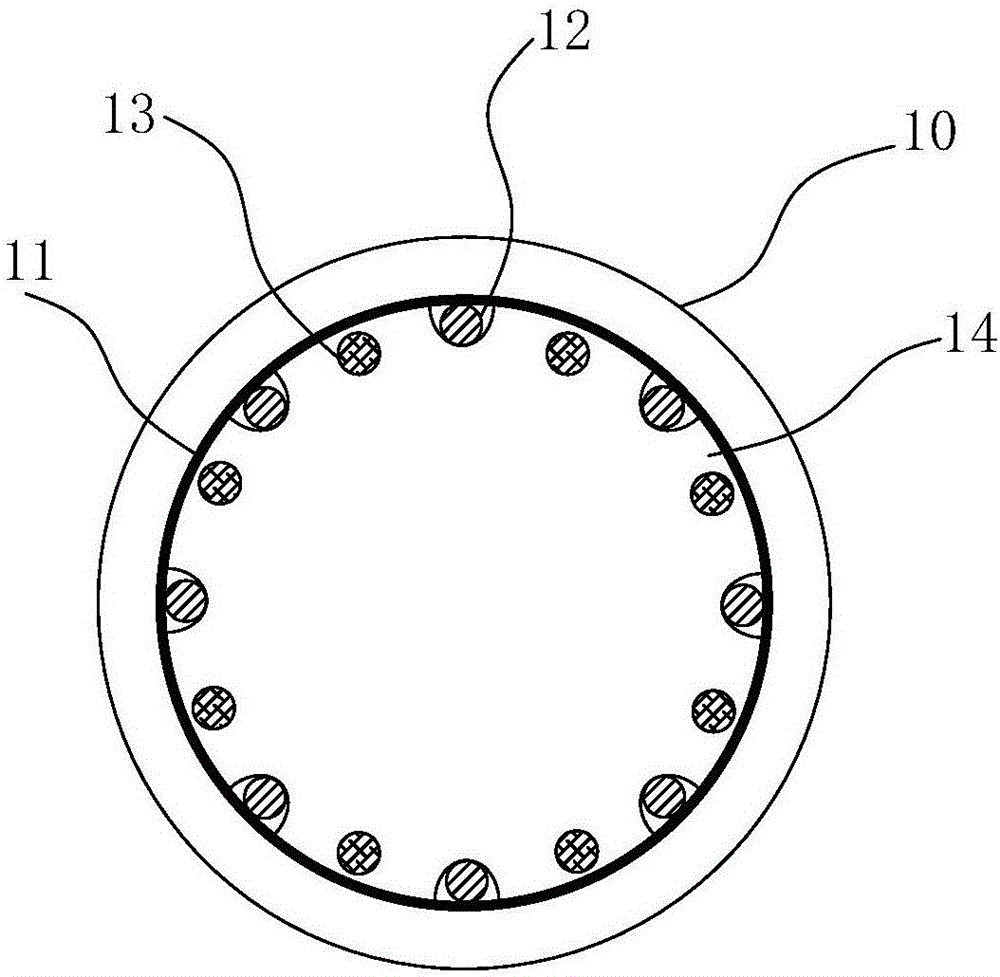

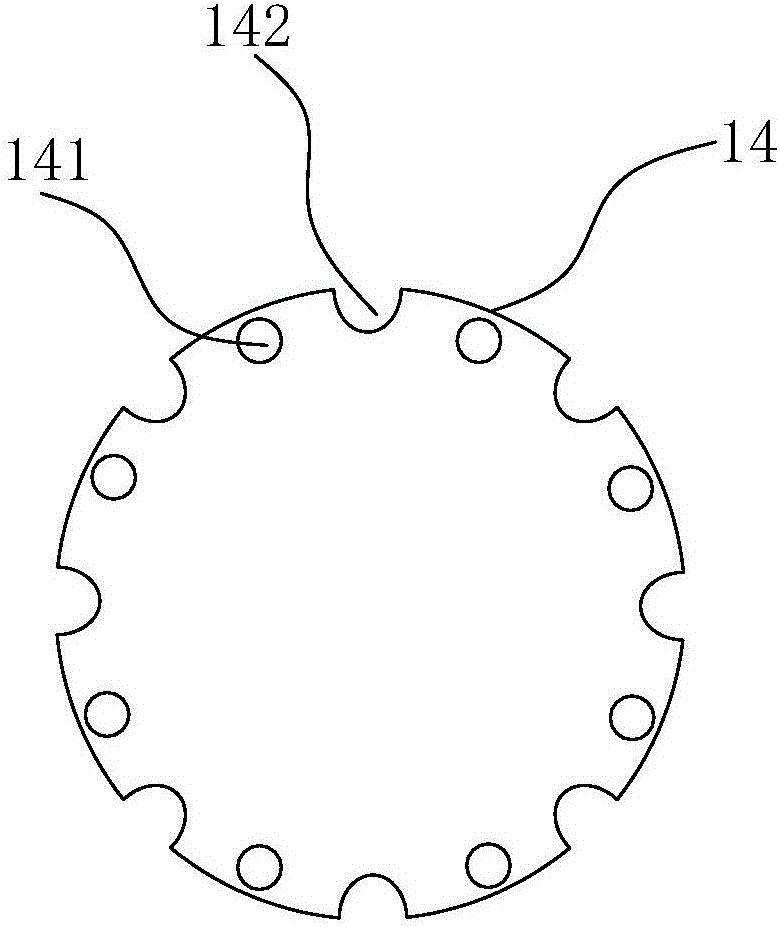

[0022] Such as figure 1 As shown, the present invention includes stirrups 11, prestressed steel bars 12 and glass fiber bars 13 arranged along the length direction of the prefabricated pile 10, and the prestressed steel bars 12 are welded at intervals in the circumferential direction of the stirrups 11 to form a cage A positioning plate 14 is clamped inside the cage, and a positioning hole 141 is provided on the positioning plate 14 for the glass fiber ribs 13 to pass through. The positioning plate 14 of the present invention is stuck in the cage, and secondly, the glass fiber reinforcement 13 is positioned and installed in the cage after passing through the positioning hole 141. The installation position of the fiber reinforcement 13 remains stable and reliable, that is, the steel skeleton cage structure of the present invention is more reliable, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com