Triangularly modular ecological sea wall

A modular and ecological technology, applied in dikes, jetties, embankments, etc., can solve problems such as poor defense against storm surges, slow embankment speed, and insufficient stability of sea dikes, so as to achieve stable and reliable structures and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

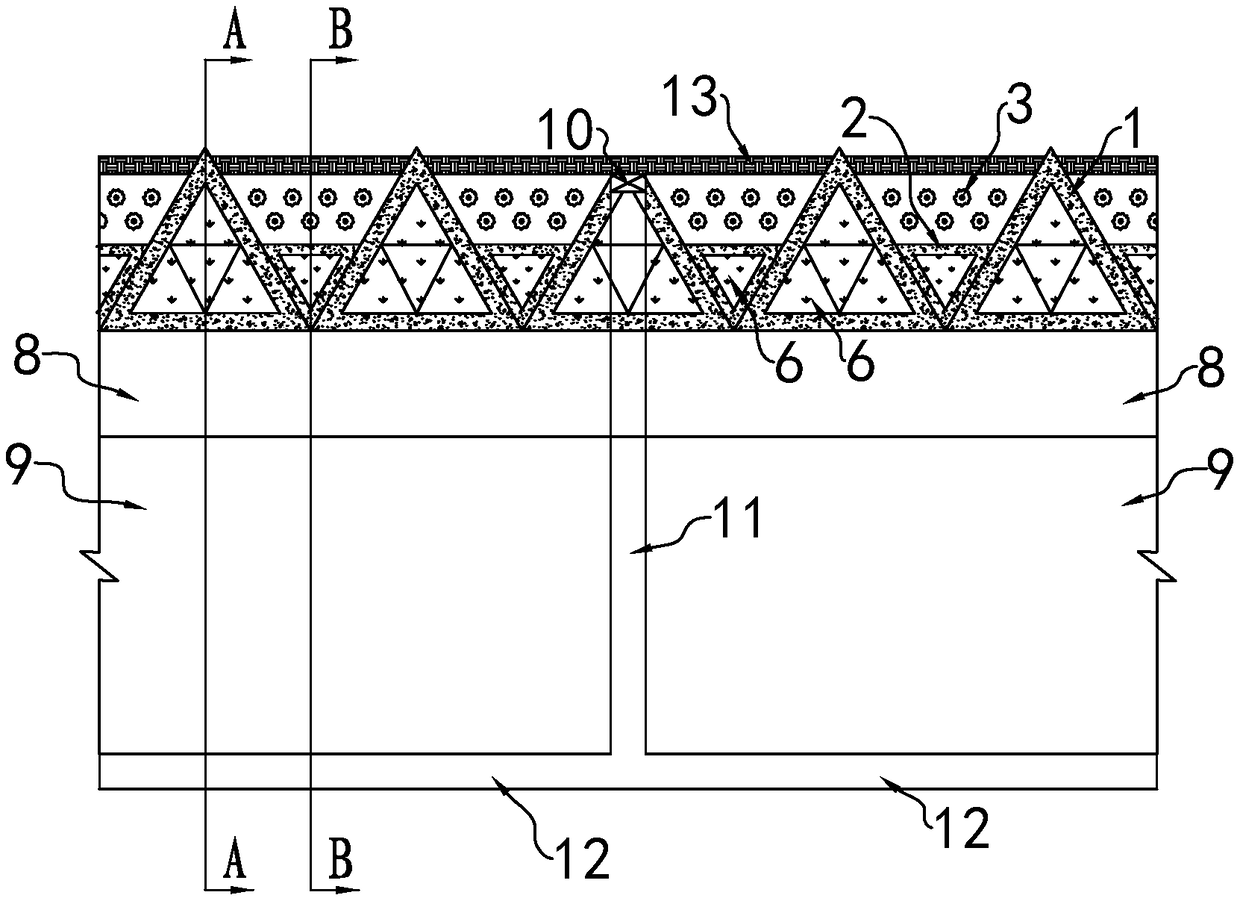

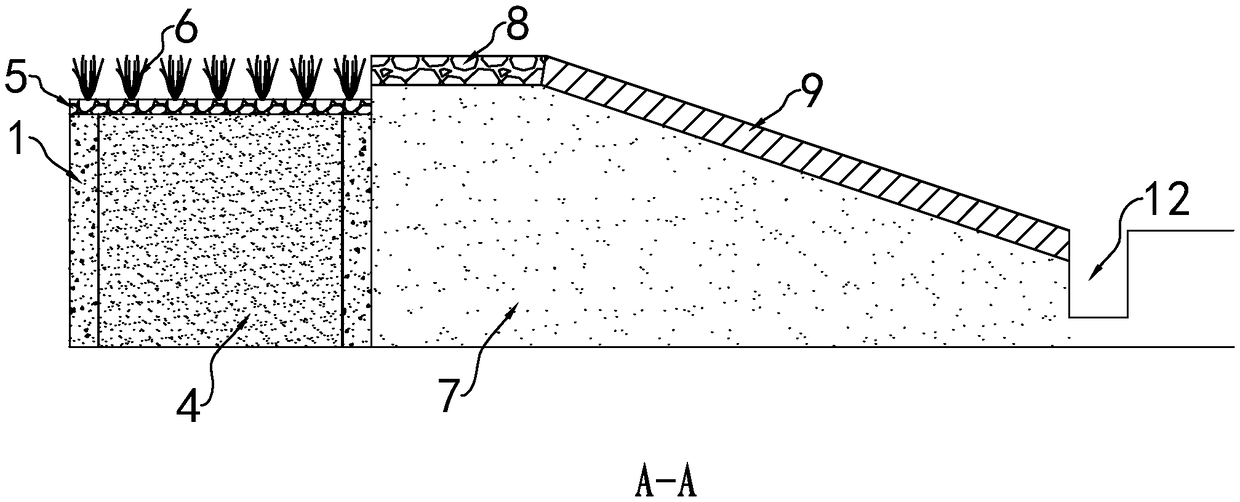

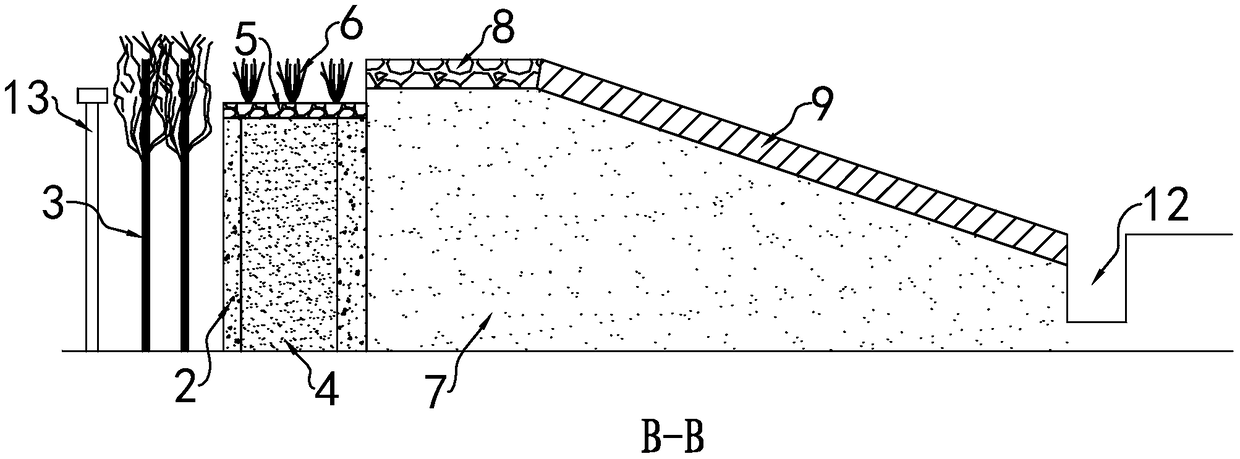

[0022] refer to Figures 1 to 3 , a triangular modular ecological seawall, including several first prefabricated frames 1 arranged in an array, and a second prefabricated frame 2 filling the gap between the first prefabricated frames 1 and two adjacent first prefabricated frames 1 The anti-wave forest 3, the first prefabricated frame 1 and the second prefabricated frame 2 are cylindrical and have a triangular cross-sectional shape, and the inner chambers of the first prefabricated frame 1 and the second prefabricated frame 2 are filled with first sea sand 4 respectively. The material of the first prefabricated frame 1 and the second prefabricated frame 2 in this embodiment is concrete, which has the characteristics of corrosion resistance and impact resistance. The first prefabricated frame 1 and the second prefabricated frame 2 are convenient for prefabricated and modularized construction, and their interiors are filled with sea sand, which can be obtained on-site at the coas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com