Aluminum alloy formwork for buildings and method for applying aluminum alloy formwork

An aluminum alloy formwork, a technology used in construction, applied in the direction of construction, building structure, formwork/formwork components, etc., to achieve the effect of fewer seams, high construction efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

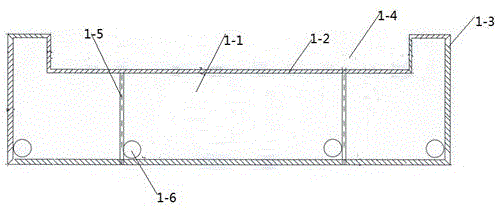

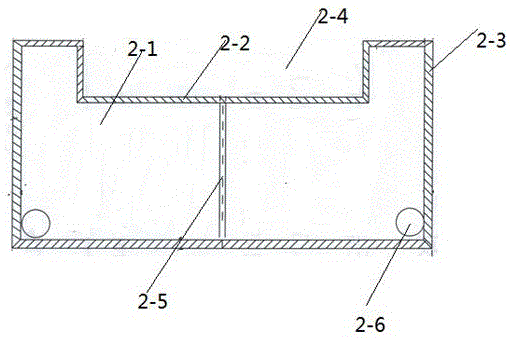

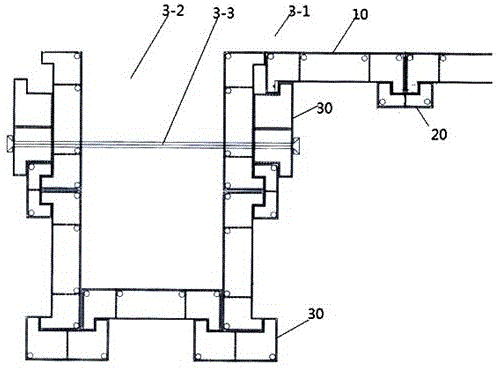

[0032] The invention provides an aluminum alloy formwork for construction. The aluminum alloy formwork for construction is composed of a general-purpose flat aluminum plate and a reinforced buckle aluminum plate, such as figure 1 and figure 2 As shown, the general plane aluminum plate and the reinforced buckle aluminum plate are respectively "concave" hollow structures, including hollow cavities 1-1, 2-1 and frames 1-2, 2-2, and the frames include convex edges 1- 3, 2-3 and grooves 1-4, 2-4, the height of the convex edge of the universal flat aluminum plate is equal to the height of the groove of the reinforced buckle aluminum plate, and the sum of the widths of the two convex edges of the universal flat aluminum plate is equal to the concave of the reinforced buckle aluminum plate The width of the groove is such that when two convex sides of the common plane aluminum plates are connected and placed in parallel for splicing, the groove of the buckle-enhanced aluminum plate ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com