Method for preparing zinc oxide-doped titanium dioxide nanotube on pure titanium surface

A technology of titanium dioxide and zinc oxide, applied in the field of material surface modification, can solve the problems of uncontrollable release of silver ions, weak adsorption of silver particles, influence on cell function, etc., and achieves the promotion of osteoblast differentiation, inhibition of infection, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

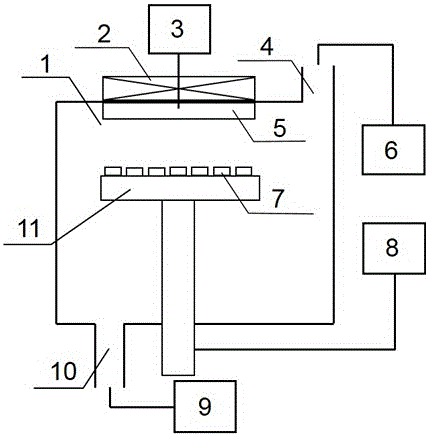

[0027] Such as figure 1 As shown, the coating device adopted in the present invention comprises a vacuum chamber 1, a permanent magnet 2 is arranged on the outer surface above the vacuum chamber 1, and a titanium-zinc alloy target 5 is arranged on the inner wall of the vacuum chamber 1 corresponding to the permanent magnet 2, and the titanium-zinc alloy target 5 is connected to the sputtering power supply 3, and a pure titanium sample 7 is provided inside the vacuum chamber 1, and the pure titanium sample 7 is placed under the titanium-zinc alloy target 5, and the pure titanium sample 7 is placed on the sample stage 11, and the sample stage 11 is T-shaped, the lower end of the sample stage 11 is outside the vacuum chamber 1, the lower end of the sample stage 11 is connected to the bias power supply 8, the upper part of the vacuum chamber 1 is provided with an air outlet 4, the outer side of the air outlet 4 is connected to the vacuum device 6, and the lower end of the vacuum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com