Antibacterial coating with bacterial enzyme response function, functional material with antibacterial coating and preparation method of functional material

An antibacterial coating, functional material technology, applied in coatings, epoxy coatings, antifouling/underwater coatings, etc., can solve problems such as high biological toxicity, body inflammation and immune response

- Summary

- Abstract

- Description

- Claims

- Application Information

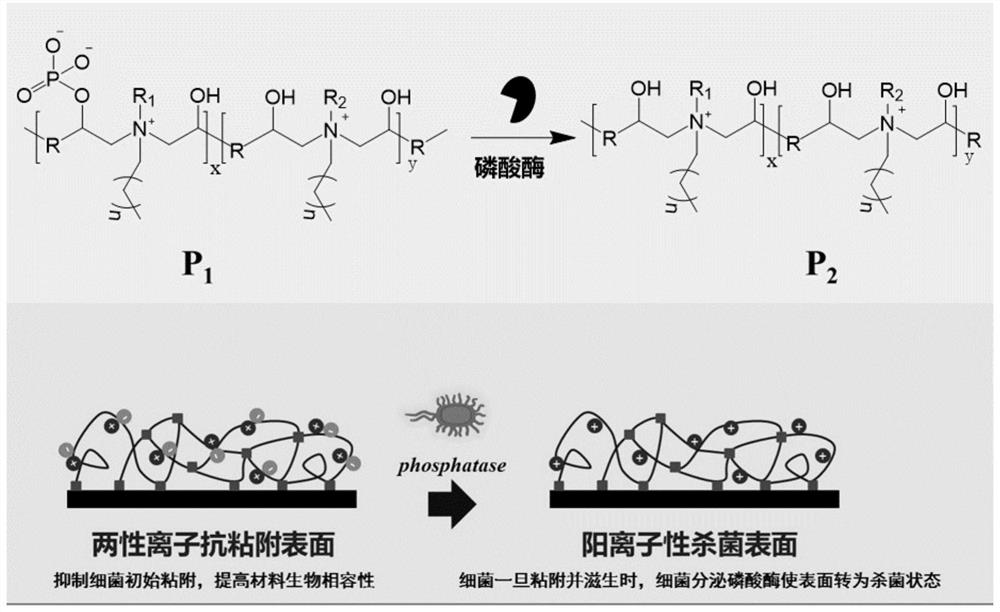

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0191] The present invention provides a method for preparing a functional material with an antibacterial coating described in any one of the above technical solutions, characterized in that it comprises the following steps:

[0192] 1) will have formula (I A ) structure of the alkylamine, the compound containing the R structure and a solvent for polymerization reaction, the first intermediate is obtained after precipitation;

[0193]

[0194] The compound containing R structure is selected from formula (I R1 )~(I R3 ) any one or more of the structures shown in );

[0195]

[0196] Wherein, n1, n2 or n3 are each selected from an integer greater than or equal to 1;

[0197] 2) reacting the first intermediate, phosphorus trichloride, organic base and solvent obtained in the above steps, and then dialysis to obtain the second intermediate;

[0198] 3) the second intermediate obtained in the above steps, having R 1 x 1 Monomer of structure, with R 2 x 2 The monomer of...

Embodiment 1

[0314] a. Dissolve 0.48g of n-hexylamine and 1.65g of ethylene glycol glycidyl ether in 25mL of dimethyl sulfoxide, react at 50°C for 12h, precipitate and centrifuge with 125mL of ether, wash the precipitated product 3 times with ether and put it in Vacuum drying in a vacuum oven for 12 hours;

[0315] b. Dissolve the product of step a in 20 mL of dimethyl sulfoxide to form a 40 mg / mL solution, add dropwise 0.015 mL of phosphorus trichloride and 0.02 mL of pyridine, react at room temperature for 3 hours, and put the product into a dialysis bag with a molecular weight cut-off of 3000 Da Dialysis in deionized water for 24 hours, the product was completely frozen in a refrigerator at -20°C, and then freeze-dried on a lyophilizer for 24 hours to remove moisture and collect the product;

[0316] c. Dissolve 200 mg of the product of step b, 20 mg of methyl iodide and 18.8 mg of 3-benzoylbenzyl bromide in 30 mL of dimethyl sulfoxide, react at 60°C for 8 hours, precipitate the reacted...

Embodiment 2

[0320] a. Dissolve 0.95g of n-dodecylamine and 1.80g of propylene glycol diglycidyl ether in 32mL of dimethyl sulfoxide, react at 55°C for 18h, and then precipitate with 125mL of n-hexane. The precipitated product is washed 5 times with n-hexane and then vacuum-dried for 12h ;

[0321] b. Dissolve the product of step a in 25mL dimethyl sulfoxide to make a 40mg / mL solution, add dropwise 0.02mL of phosphorus trichloride and 0.03mL of pyridine, react at room temperature for 4.5h, and put the product into a dialysis bag with a molecular weight cut-off of 3000Da The product was dialyzed in deionized water for 24 hours, and the product was completely frozen in a refrigerator at -20°C, and then freeze-dried on a lyophilizer for 24 hours to remove moisture and collect the product;

[0322] c. Dissolve 200 mg of the product of step b, 120 mg of ethyl bromide and 54 mg of anthraquinone-2-carboxylic acid in 50 mL of dimethyl sulfoxide, react at 60°C for 8 hours, and post-process to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com