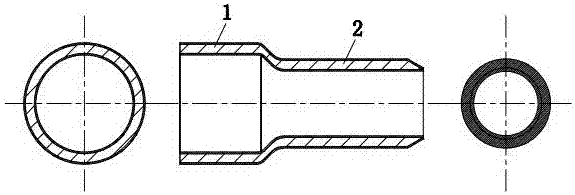

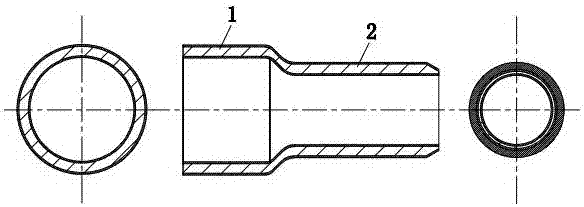

Production technology for connecting pipe of compressor

A production process and technology for connecting pipes, applied in the field of production technology of connecting pipes of compressors, can solve the problems such as difficulty in controlling the accuracy and stability of centerless grinding, easy falling off of electroplated copper layers, deformation of parts of compressor pump bodies, etc. The risk of falling off, improving the stability of the assembly, reducing the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of production process of compressor connecting pipe of the present embodiment, it comprises the following steps:

[0038] 1. Material selection: choose copper-iron composite board or copper-iron composite pipe as raw material;

[0039] 2. Continuous multi-stage stamping and stretching forming or pipe fitting processing process forming:

[0040] (1) Continuous multi-stage stamping and stretching:

[0041] Step 1. Blanking: use punching equipment to punch the copper-iron composite plate into a blank of a certain size;

[0042] Step 2, multi-stage stretching: carry out 4-stage stretching to the blank obtained in step 1, and control the deformation rate of each stage of stretching to 10%, and the overall deformation rate to 15%;

[0043] Step 3, flashing: perform flashing treatment on the semi-finished product after multi-stage stretching in step 2;

[0044] Step 4, punching: punching the semi-finished product that has completed the flashing treatment in step 3; ...

Embodiment 2

[0054] A kind of production process of compressor connecting pipe of the present embodiment, it comprises the following steps:

[0055] 1. Material selection: choose copper-iron composite board or copper-iron composite pipe as raw material;

[0056] 2. Continuous multi-stage stamping and stretching forming or pipe fitting processing process forming:

[0057] (1) Continuous multi-stage stamping and stretching:

[0058] Step 1. Blanking: use punching equipment to punch the copper-iron composite plate into a blank of a certain size;

[0059] Step 2, multi-stage stretching: carry out 2-stage stretching to the blank obtained in step 1, and control the deformation rate of each stage of stretching to 5%, and the overall deformation rate to 5%;

[0060] Step 3, flashing: perform flashing treatment on the semi-finished product after multi-stage stretching in step 2;

[0061]Step 4, punching: punching the semi-finished product that has completed the flashing treatment in step 3;

[...

Embodiment 3

[0071] A kind of production process of compressor connecting pipe of the present embodiment, it comprises the following steps:

[0072] 1. Material selection: choose copper-iron composite board or copper-iron composite pipe as raw material;

[0073] 2. Continuous multi-stage stamping and stretching forming or pipe fitting processing process forming:

[0074] (1) Continuous multi-stage stamping and stretching:

[0075] Step 1. Blanking: use punching equipment to punch the copper-iron composite plate into a blank of a certain size;

[0076] Step 2, multi-stage stretching: carry out 8-stage stretching to the blank obtained in step 1, and control the deformation rate of each stage of stretching to 15%, and the overall deformation rate to 30%;

[0077] Step 3, flashing: perform flashing treatment on the semi-finished product after multi-stage stretching in step 2;

[0078] Step 4, punching: punching the semi-finished product that has completed the flashing treatment in step 3; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com