Manufacturing methods of new leather layer type shoe heel and shoe sole, and shoes

A manufacturing method and technology for shoe heels, which are applied to shoe heels, heel pads, and shoe-making machinery, etc., can solve problems such as unevenness and insufficient strength, increase costs, waste resources, etc., and achieve recycling and utilization, Easy to implement and manufacture, achieving the effect of environmentally friendly manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

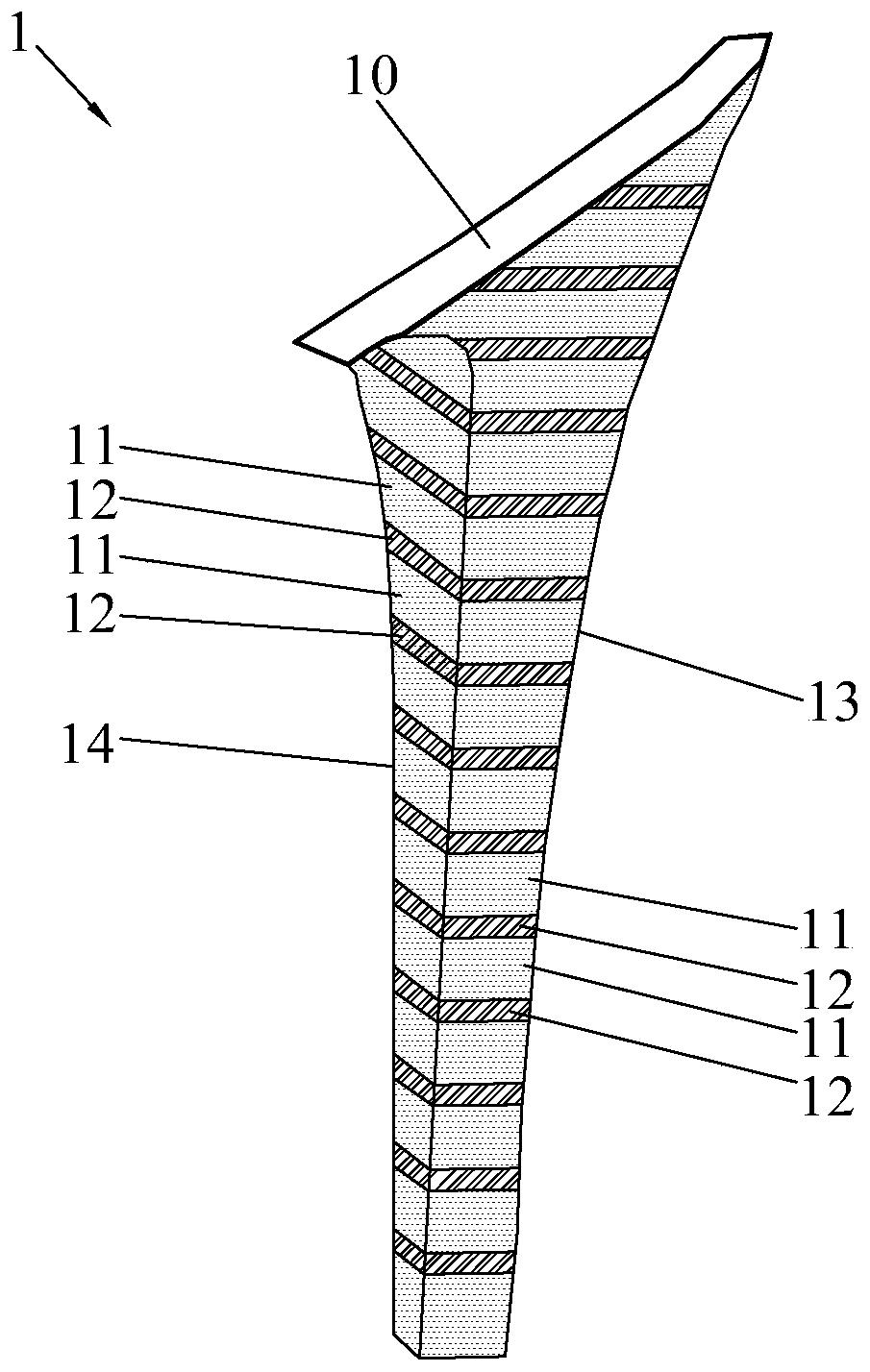

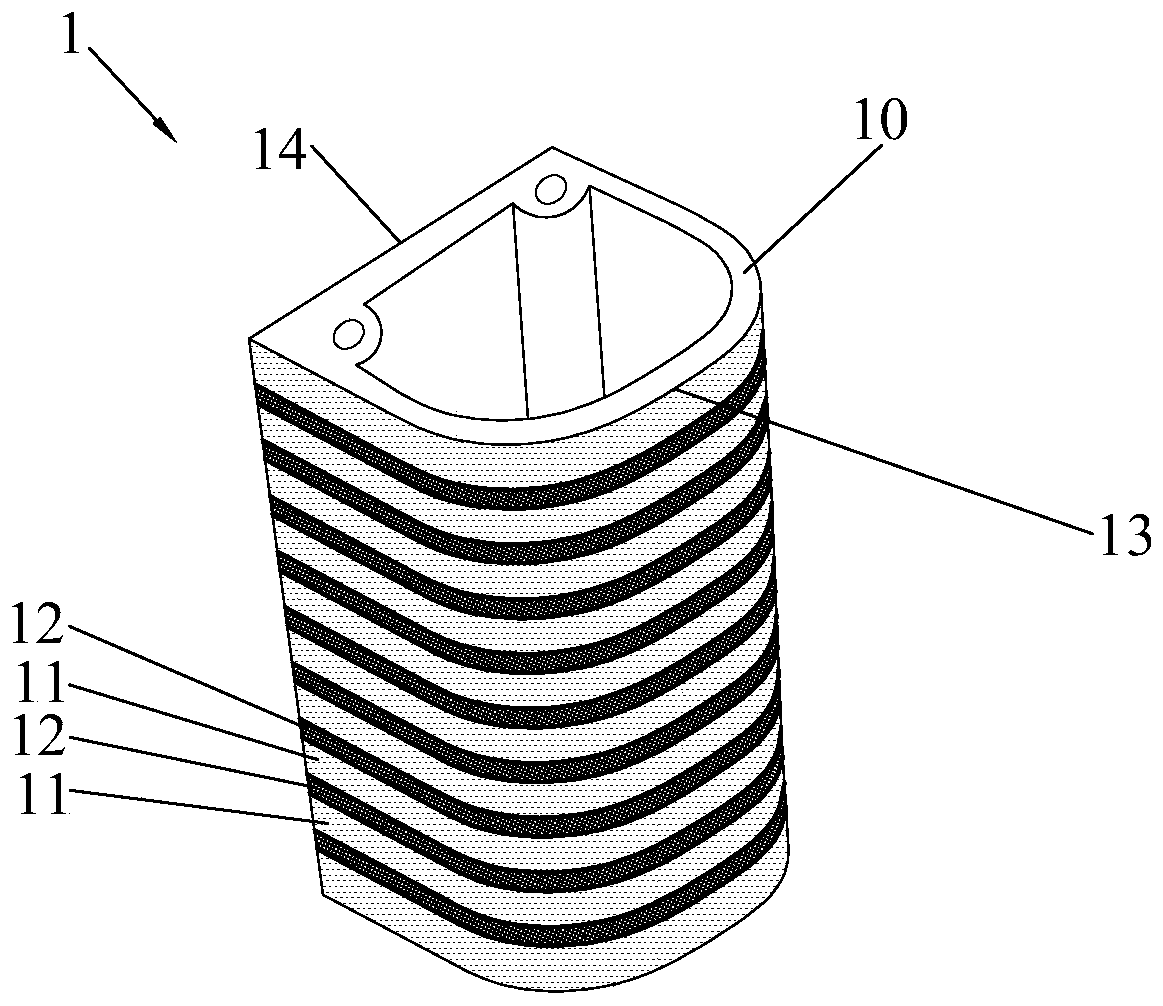

[0031] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

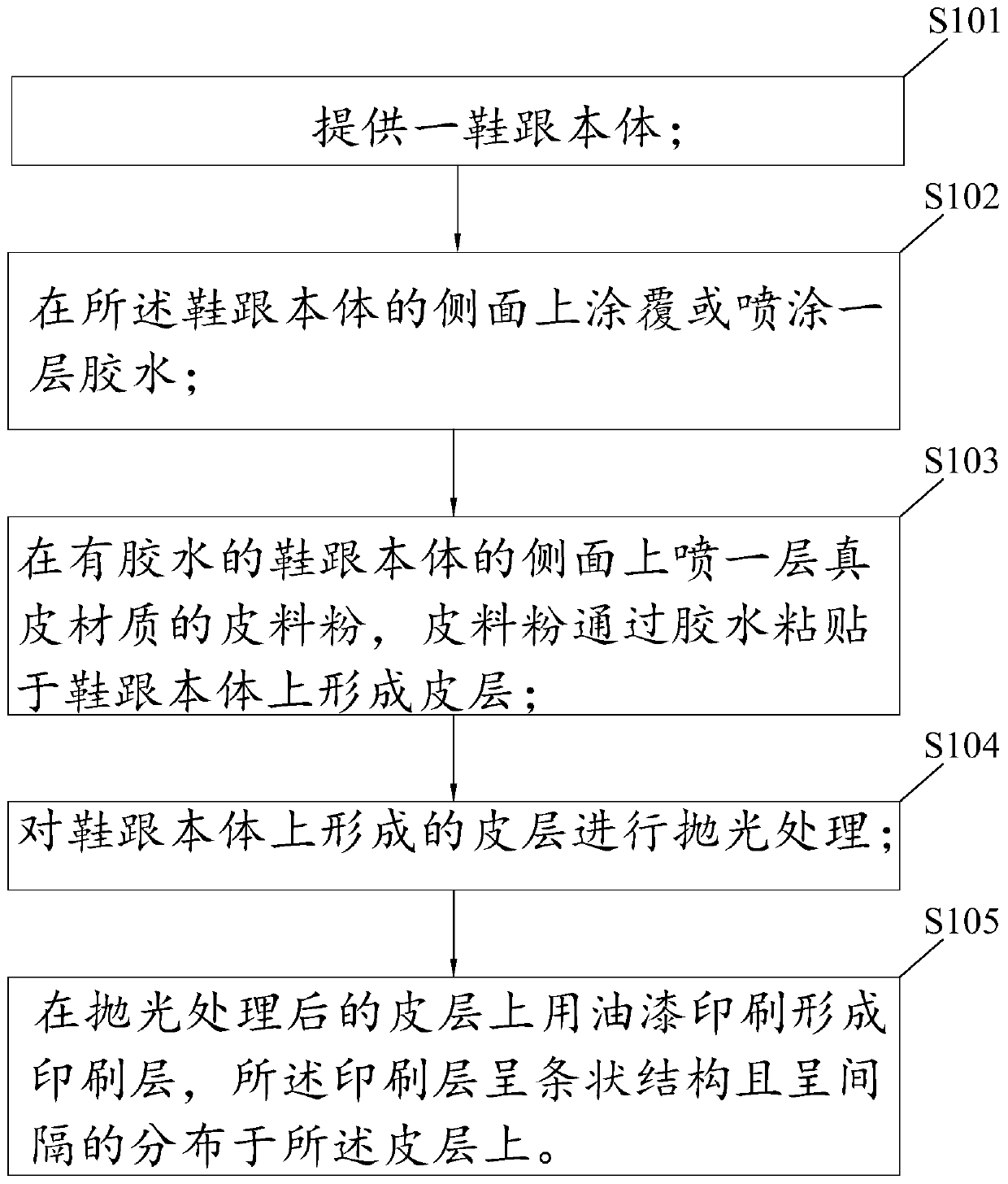

[0032] Such as figure 1 Shown, the manufacture method of new layer leather formula heel of the present invention, it comprises the steps:

[0033] S101: provide a heel body;

[0034] S102: coating or spraying a layer of glue on the side of the heel body;

[0035] S103: Spray a layer of leather powder on the side of the heel body with glue, and the leather powder is pasted on the heel body by glue to form a cortex; Leather scraps are used to make leather powder, or various used leather goods are recycled and disinfected to make leather powder; more specifically, leather powder can be prepared by crushing leather.

[0036] S104: polishing the cortex formed on the heel body; and

[0037] S105: Printing with paint on the polished skin layer to form a printing layer, the printing layer has a strip structure and is distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com