Mixed-bed resin for polishing condensate of compatible supercritical unit

A condensate polishing, supercritical unit technology, applied in ion exchange water/sewage treatment, bulk chemical production, etc., can solve problems such as inability to mix operation, incompatibility, etc., achieve recycling and utilization, and achieve good compatibility Sexual, far-reaching socially meaningful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: A kind of mixed-bed resin for condensate polishing of compatible supercritical unit is characterized in that: it is synthesized by the cation exchange resin whose H-type rate must be ≥ 99.9% and the anion-exchange resin whose OH-type rate must be ≥ 95.0%. Mixed operation of powdered ion exchange resin and imported condensate special resin R&H 252H, 900Cl, or DOWEX650C, 550A, or LEWATIT S100, M800. During the mixed operation, the supercritical unit condensate polishing mixed bed operates at a high flow rate above 120m / h. The operating temperature can reach around 70°C. The mixed-bed resin for condensate polishing of the compatible supercritical unit uses styrene and divinylbenzene as processing raw materials, wherein the particle size of the compatible mixed-bed ion-exchange resin is processed to have a specific specific gravity and a specific narrow range of particle size, so that Uniform particle size, functional groups are basically not easy to degrade, ...

Embodiment 2

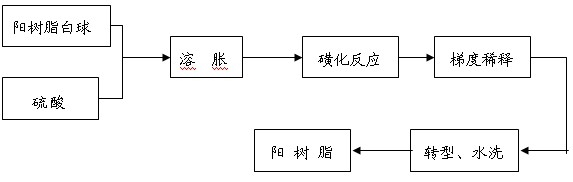

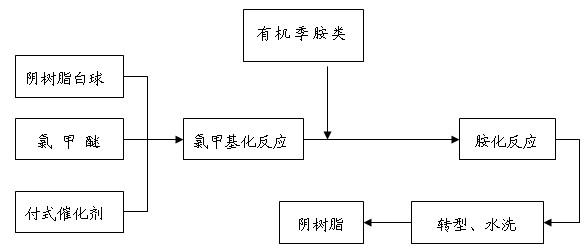

[0017] Embodiment 2: with reference to attached Figure 1-5 . A mixed-bed resin for condensate polishing in a compatible supercritical unit uses styrene and divinylbenzene as processing raw materials. Uniform particle size, functional groups are basically not easy to degrade, high regeneration degree anion exchange resin is not affected by impurities in the air such as CO 2 Pollution, does not bring in new mechanical impurities and metal ions. It can be used alone in the mixed bed system for supercritical unit condensate polishing, and can be mixed with similar products imported from abroad, with good mixing compatibility.

[0018] The mixed-bed resin synthesis process for the condensate polishing treatment of the compatible supercritical unit,

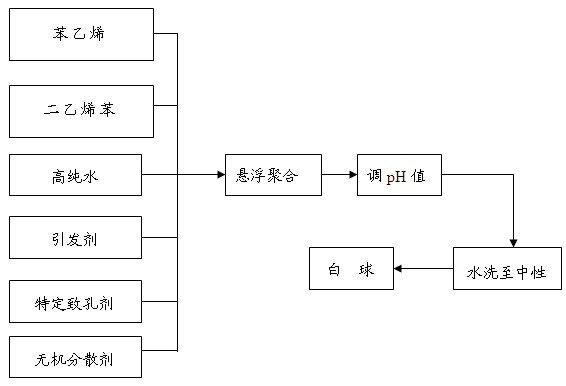

[0019] ⑴White ball polymerization process:

[0020] Cationic resin white ball polymerization process:

[0021] Explanation: The white ball polymerization process is oil phase: water phase = 1: 1.62

[0022] In the oil phase:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com