System for dead steam recovery and shaft heating and method

A technology of exhaust steam recovery and wellbore, which is applied in the system and system field of exhaust steam recovery and heating wellbore, which can solve the problems of short service life of traps, poor return water, and large number of traps, so as to achieve recovery and utilization, Increased release speed and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0098] There are three air intake shafts in Shangwan Coal Mine Industrial Plaza, which are the main inclined shaft, the first sub-level tunnel, and the second sub-level tunnel, and there are three heater rooms respectively. The steam boiler about 500m away from the air inlet shaft supplies steam to the heater room through the steam inlet pipe. The air is sucked into the heater room by the fan. The bottom outlet of the steam heat exchanger is returned to the condensed water collection tank of the boiler room through the condensed water pipe, and a large amount of exhaust steam in the condensed water is discharged to the atmosphere from the exhausted steam exhaust pipe at the top of the condensed water collected water tank. Every heating season, a large amount of exhausted steam is evacuated to form fog clouds and light rain. This not only causes waste of heat and water in exhaust steam, but also has adverse effects on the atmosphere.

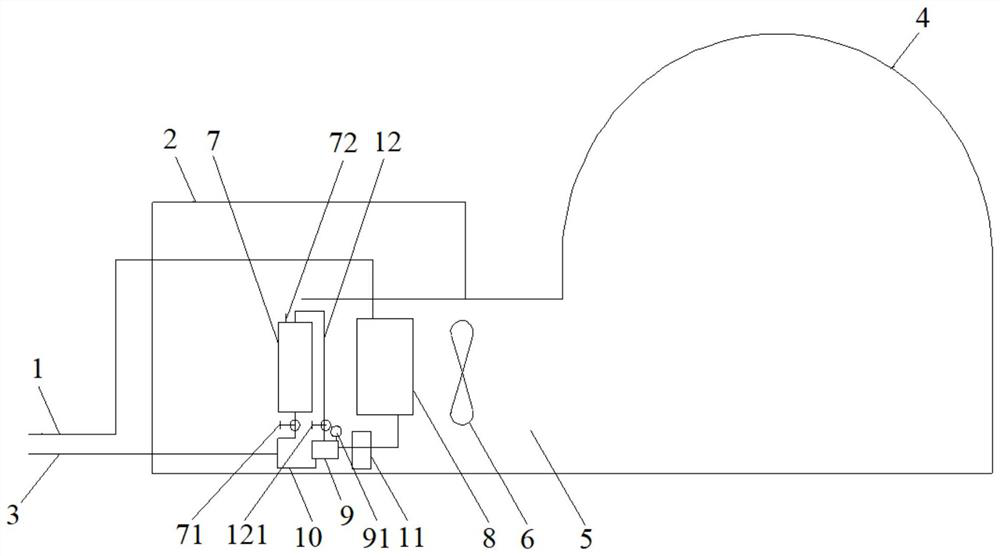

[0099] instead use as figure 1 After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com