Manufacturing method of multi-purpose zinc clad steel

A manufacturing method, zinc-clad steel technology, applied in the field of multi-purpose zinc-clad steel manufacturing, can solve problems such as chemical pollution, and achieve the effects of uniform zinc layer thickness, flexible production, and flexible adjustment of zinc layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

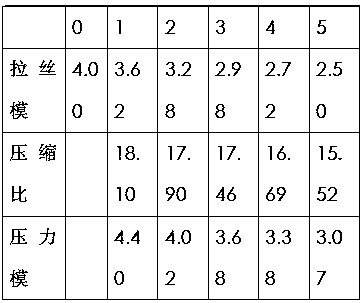

[0015] a. Rough drawing: Select Ф5.5mm Q195 hot-rolled wire rod, use bending peeling to remove scale, enter high-speed continuous wire drawing machine, use calcium-based wire drawing powder and pressure die to draw into Ф3.2mm steel wire (tensile strength 480MPa), use 1250mm steel I-shaped wheel for shafting and take-up.

[0016] b. Steel wire cladding: 1250mm steel I-shaped wheel is put into the belt machine, choose 80-mesh abrasive belt, grind the surface of the steel wire online, and blow off the surface of the steel wire with an online air knife; heat the steel wire in the online intermediate frequency furnace to 250 degrees; select two discs Ф9 .5mm pure zinc wire rod, cladding guide die Ф3.4mm, extrusion die Ф3.4mm, the extrusion die and guide die are assembled in the cavity of the coating machine, the nose groove size of the extrusion die and guide die is 3.0mm ;The temperature of the mold cavity is heated to 200 degrees, the extrusion wheel is conveyed for 3 turns, ext...

Embodiment 2

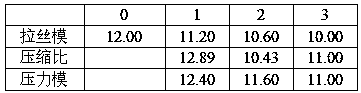

[0021] a. Rough drawing: Select Ф12mm Q195 hot-rolled wire rod, use bending peeling to remove scale, enter high-speed continuous wire drawing machine, use calcium-based wire drawing powder and pressure die to draw into Ф11.5mm steel wire (tensile strength 450MPa), use 1250mm steel wire The I-shaped wheel makes the shaft and takes up the line.

[0022] b. Steel wire covering. The 1250mm steel I-shaped wheel is put into the abrasive belt machine, and the 80-mesh abrasive belt is selected, the surface of the steel wire is polished online, and the surface of the steel wire is blown clean by an online air knife; the steel wire is heated to 250 degrees in the online intermediate frequency furnace; two discs of Ф9.5mm pure zinc wire rod are selected , the coating guide die is Ф11.7mm, the extrusion die is Ф12mm, the extrusion die and the guide die are assembled in the cavity of the coating machine, and the distance between the nose groove of the extrusion die and the guide die is 5.0...

Embodiment 3

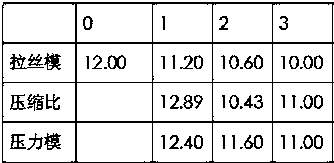

[0025] Example 3: a. Rough drawing: select Ф5.5mm Q195 hot-rolled wire rod, and use bending peeling to remove oxygen

[0026] The iron sheet is melted into a high-speed continuous wire drawing machine and drawn into a Ф2.0mm steel wire (tensile strength 480MPa) by using calcium-based wire drawing powder and a pressure die, and the wire is drawn by a 1250mm steel I-shaped wheel.

[0027] b. Steel wire covering. The 1250mm steel I-shaped wheel is put into the abrasive belt machine, and the 120-mesh abrasive belt is selected, the surface of the steel wire is polished online, and the surface of the steel wire is blown clean by an online air knife; the steel wire is heated to 250 degrees in the online intermediate frequency furnace; two discs of Ф9.5mm pure zinc wire rod are selected , Coating guide die Ф2.2mm, extrusion die Ф4.0mm, nasal groove size 3.0mm are assembled in the mold cavity of the coating machine, the temperature of the mold cavity is heated to 200 degrees, the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com