Cleaning liquid applied to optical glass substrate and preparation method

A technology for optical glass and cleaning liquid, applied in the direction of chemical instruments and methods, preparation of detergent mixture composition, detergent composition, etc., can solve problems such as pollution, achieve convenient use, easy automatic mass production, and simple production method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

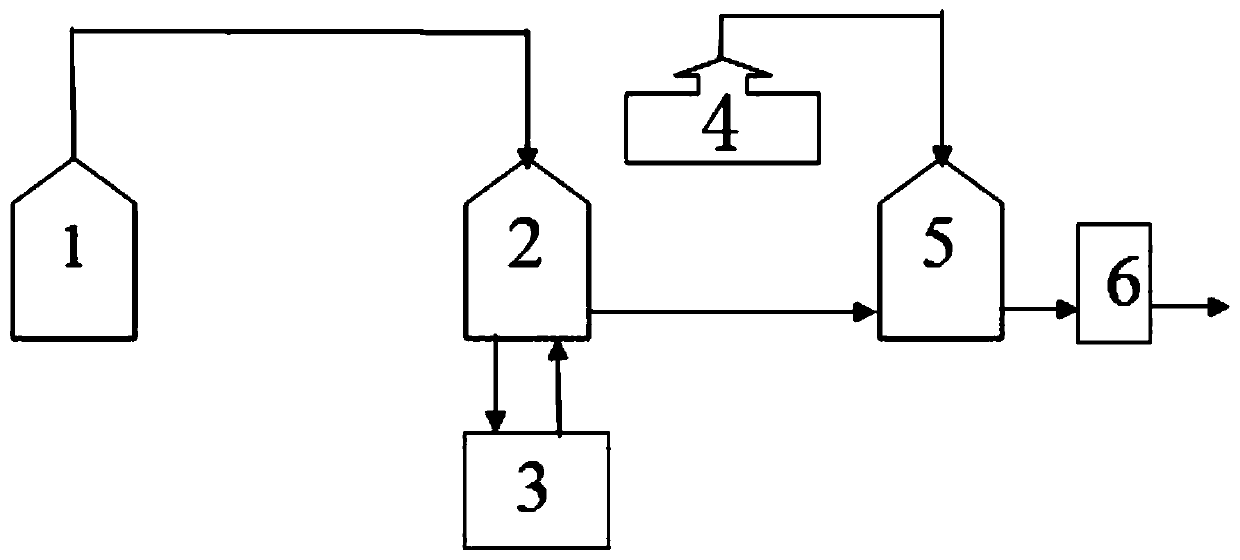

[0034] Embodiment one of the present invention firstly provides a kind of cleaning liquid that is applied to optical glass substrate, and it specifically comprises the following components by weight percentage: inorganic alkaline substance (KOH) 5.7%; Potassium carbonate (K2CO3) 2.7%; Fatty alcohol and Quaternary ammonium alcohol ether copolymer 0.03%; deionized water 91.57%. Secondly, if figure 1 As shown, a cleaning solution applied to optical glass substrates provided by Embodiment 1 of the present invention is obtained by the following preparation method:

[0035] S1: pass tap water through water-making equipment 1 to produce pure water, and detect the conductivity of the effluent;

[0036] S2: put the produced high-purity water into the first liquid storage tank 2, and cool it to a suitable temperature through the cooler 3;

[0037] S3: Store the cooled high-purity water in the second liquid storage tank 5, then add inorganic alkaline substances through the feeding cont...

Embodiment 2

[0042] Others are the same as those described in Embodiment 1, except that a cleaning solution applied to optical glass substrates provided by Embodiment 2 of the present invention includes the following components in weight percentage: inorganic alkaline substance (KOH) 10.1%; Potassium carbonate (K2C03) 1.4%; Sodium metasilicate (NaSi03) 0.1%; Fatty alcohol and quaternary ammonium salt alcohol ether copolymer 0.01%; Deionized water 88.39%. Embodiment three:

Embodiment 3

[0043] Others are the same as those described in Embodiment 1, except that a cleaning solution applied to optical glass substrates provided by Embodiment 3 of the present invention includes the following components in weight percentage: inorganic alkaline substance (KOH) 8.8%; Potassium carbonate (K2C03) 2%; Potassium chloride (KCI) 0.5%; Fatty alcohol and quaternary ammonium salt alcohol ether copolymer 0.02%; Deionized water 88.68%.

[0044] In order to further observe the cleaning effect of a kind of cleaning solution applied to optical glass substrates provided by the above-mentioned embodiments 1 to 3, the present invention adopts the following experimental means, that is, using the optical glass substrate of the photoelectric display material as the test object, and cutting 3cm*4cm Small pieces with fingerprints, dirt, glass shards and other problems on them, then immersed in 100ml of cleaning solution (this cleaning solution is obtained by diluting the cleaning solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com