Dissimilar steel welding method for martensite heat-resisting steel and austenitic heat-resisting steel

A technology of austenitic heat-resistant steel and welding method, applied in the field of dissimilar steel welding of martensitic heat-resistant steel and austenitic heat-resistant steel, can solve the problems that restrict the design, manufacture and safe operation of ultra-supercritical units, lag and other problems, to achieve significant economic and social benefits, less control parameters, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

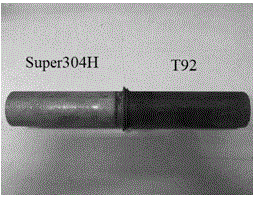

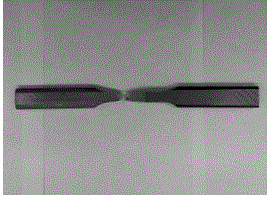

[0036] Martensitic heat-resistant steel is selected from T92 steel pipe produced by Shanghai Baosteel. Austenitic heat-resistant steel is selected from Super304H steel pipe imported from Germany. The outer diameter of T92 steel pipe is 45mm and the thickness is 9mm. The outer diameter of Super304H steel pipe is 45mm , the thickness is 9mm, and the length of the two steel pipes is 0.15m. Before welding, the welding surface of the steel pipe shall be kept clean and shall not be polluted.

[0037] The continuous drive friction welding machine used meets the following performance requirements: the friction process can achieve bipolar pressure, the first stage of pressure, the speed meets 0-1800 rpm, the friction pressure meets 0-75MPa, and the friction time meets 0-6 seconds. In the second stage of pressurization, the rotation speed meets 0-1800 rpm, the friction pressure meets 0-200MPa, and the friction time meets 0-20 seconds. In the upsetting stage, the upsetting pressure m...

Embodiment 2

[0045] Follow the steps below to weld T91 steel pipe and Super304H steel pipe

[0046] 1) According to the technical requirements of the friction welding machine, install the T91 steel pipe and the Super304H steel pipe respectively, and require the friction welding machine clamp to clamp the steel pipe. The T91 steel pipe and the Super304H steel pipe cannot shake, and the centerlines of the two steel pipes should be kept on a horizontal line;

[0047] 2) In the first stage of pressurization, the speed is 1800 rpm, the friction pressure is 50MPa, and the friction time is 5 seconds;

[0048] 3) In the second stage of pressurization, the speed is 1500 rpm, the friction pressure is 200MPa, and the friction deformation is 6mm;

[0049] 4) In the upsetting stage, the upsetting pressure is 200MPa, and the upsetting time is 5 seconds;

[0050] 5) The welded joints of martensitic heat-resistant steel pipes and austenitic heat-resistant steel pipes need to undergo local heat treatment...

Embodiment 3

[0052] 1) According to the technical requirements of the friction welding machine, install the T91 steel pipe and the Super304H steel pipe respectively, and require the friction welding machine clamp to clamp the steel pipe. The T91 steel pipe and the Super304H steel pipe cannot shake, and the centerlines of the two steel pipes should be kept on a horizontal line;

[0053] 2) In the first stage of pressurization, the speed is 1500 rpm, the friction pressure is 75MPa, and the friction time is 5 seconds;

[0054] 3) In the second stage of pressurization, the speed is 1500 rpm, the friction pressure is 150MPa, and the friction deformation is 6mm;

[0055] 4) In the upsetting stage, the upsetting pressure is 200MPa, and the upsetting time is 5 seconds;

[0056] 5) The welded joints of martensitic heat-resistant steel pipes and austenitic heat-resistant steel pipes need to undergo local heat treatment after welding to eliminate residual stress.

[0057] The heat treatment paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com