Ultrasonic-welding joining apparatus of semiconductor substrate

An ultrasonic welding and bonding device technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as physical vibration or weak weld cracks, reduced joint quality, and reduced productivity. Achieve the effects of improving joint quality, preventing the generation of environmental pollutants, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Hereinafter, the structure and operation of the ultrasonic welding and bonding device for semiconductor substrates according to the present invention will be described in detail with reference to the drawings and preferred embodiments.

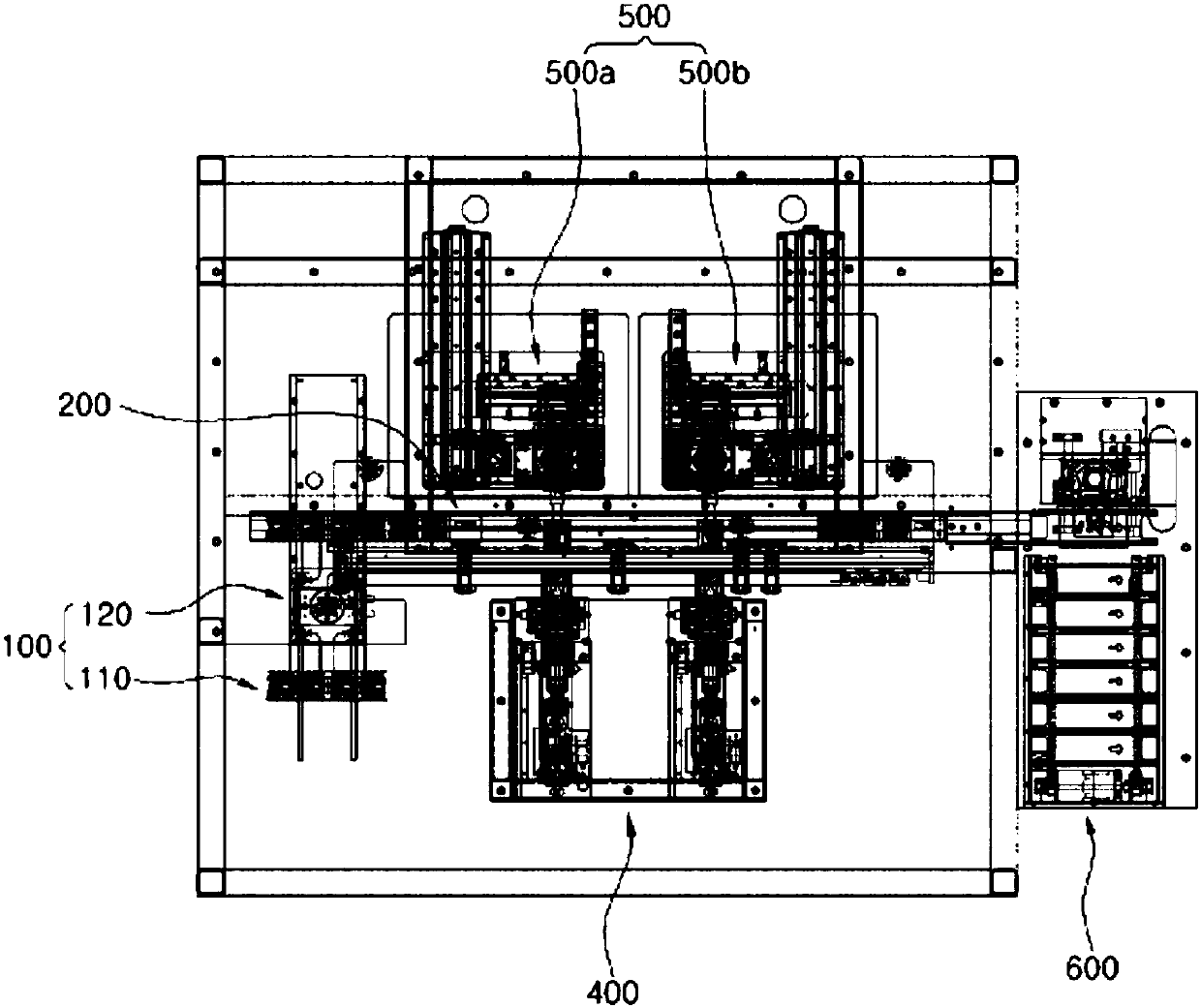

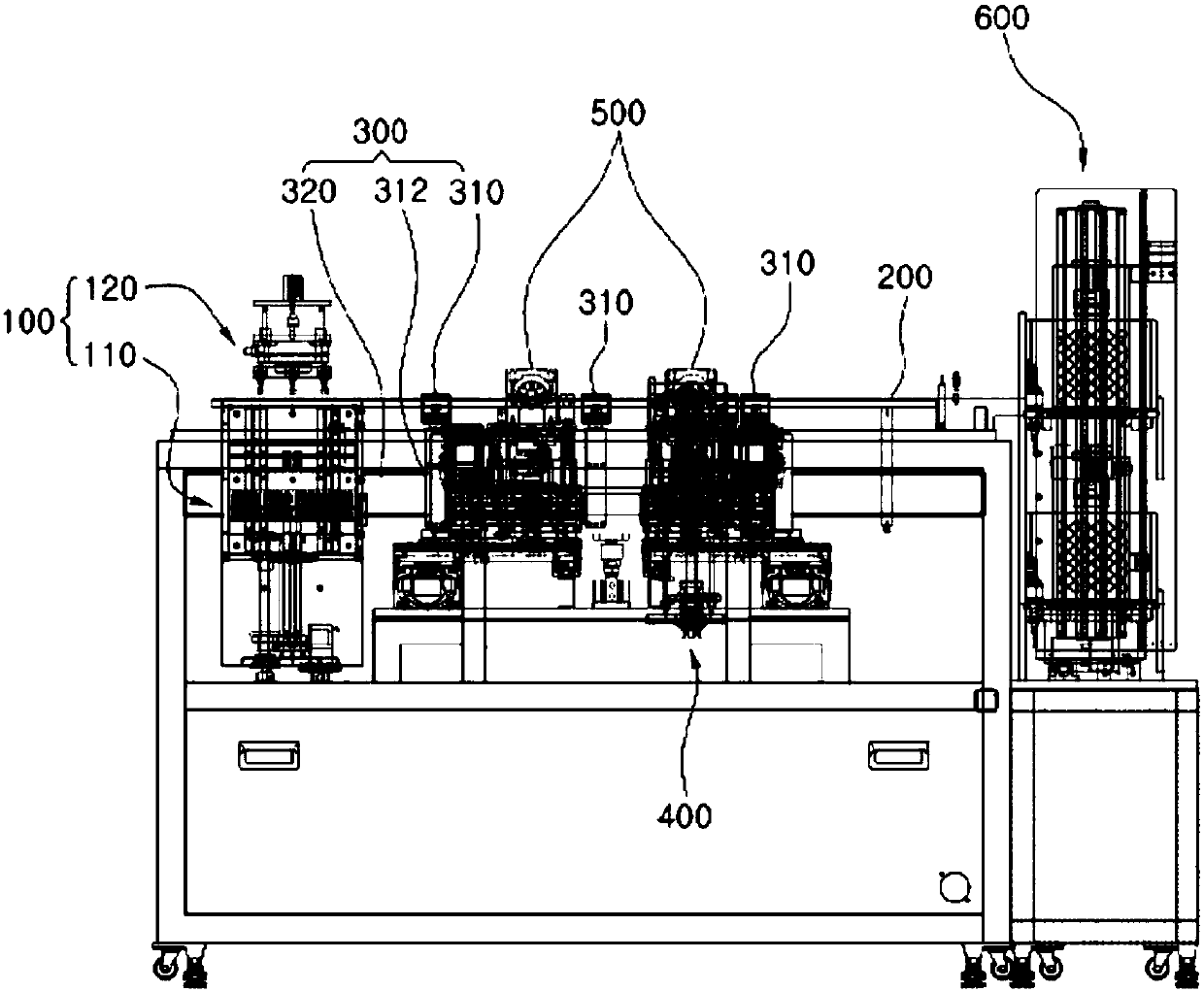

[0087] Such as figure 2 and image 3 As shown, the ultrasonic welding bonding apparatus of the present invention includes a lead frame loading unit 100 , an index rail 200 , a lead frame transfer unit 300 , a substrate loading unit 400 , an ultrasonic welding unit 500 and an unloading unit 600 .

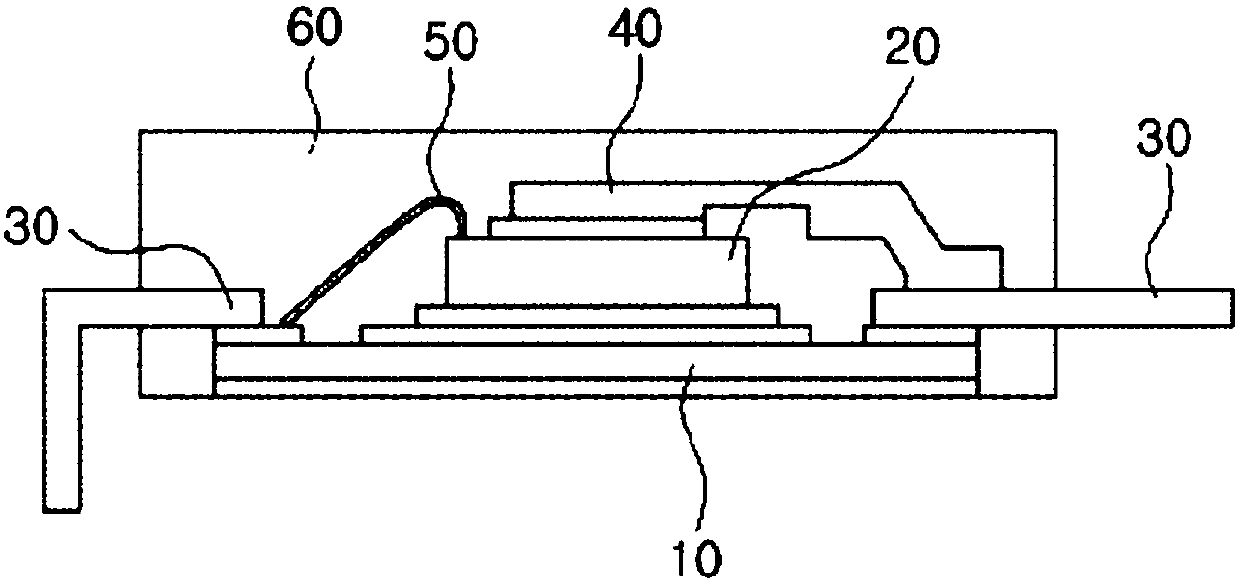

[0088] Such as Figure 4 As shown, the lead frame loader 100 is a part for automatically feeding the lead frame LF bonded to the copper-clad ceramic substrate S, and includes a stack loader 110 and a separator 120 .

[0089] The stack loader 110 lifts and moves a plurality of lead frames LF in a multi-layered state, and supplies them to the separator 120 . Such as Figure 4 As shown, the above-mentioned stack loader 110 includes: a motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com