Coating solution of coating electrode and preparation method of coating electrode

A coating electrode and solution technology, applied in the field of electrochemistry, can solve the problems of oxidation failure on the surface of the titanium substrate, affecting the electrochemical catalytic performance and service life of the coated titanium electrode, etc., so as to inhibit rapid growth and agglomeration, improve performance, and enhance service life. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

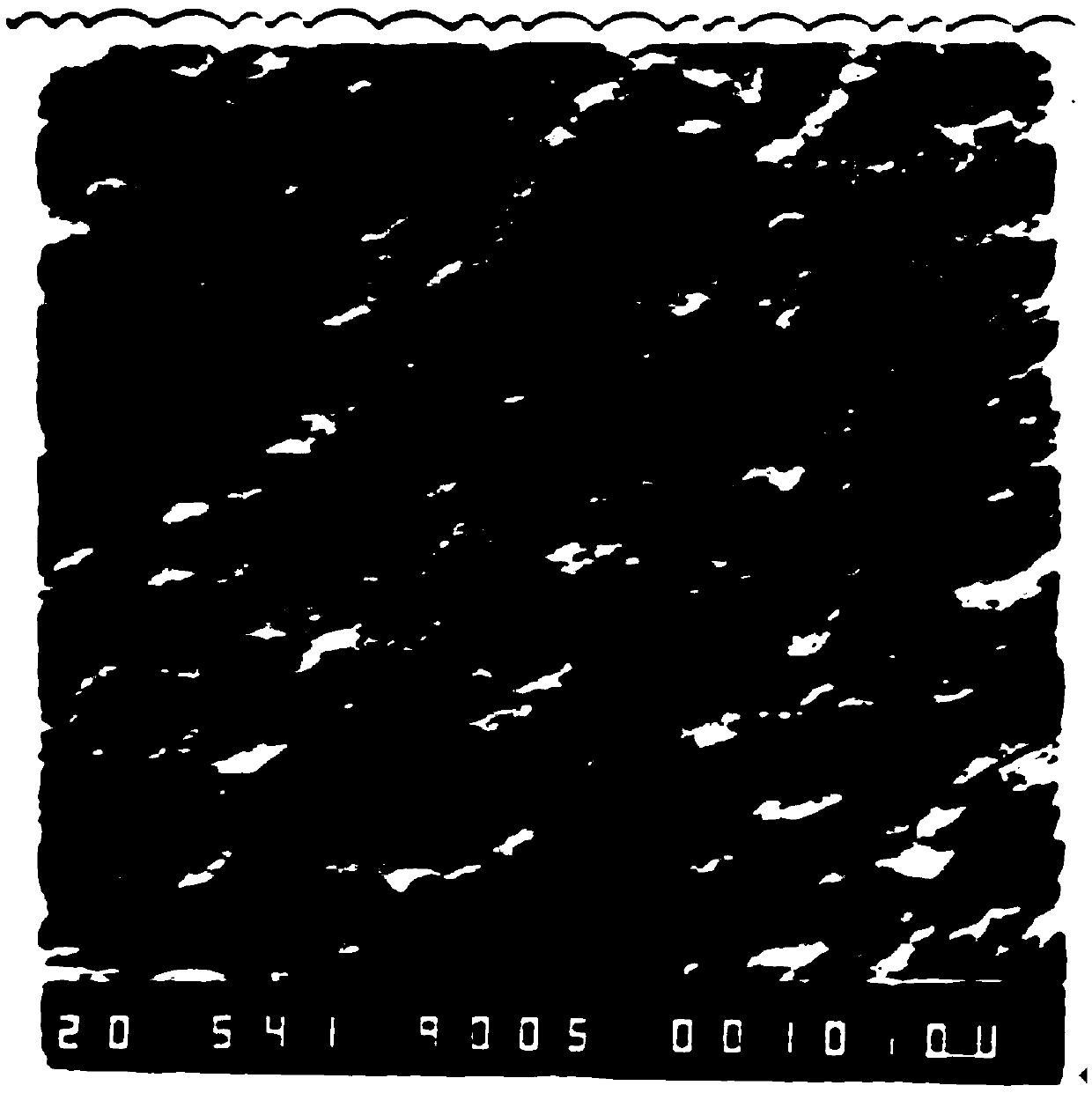

Image

Examples

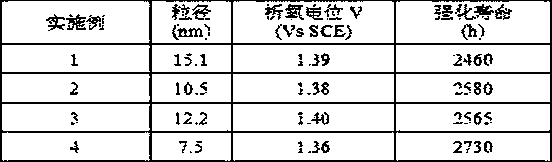

Embodiment 1

[0023] Embodiment 1: chloroiridic acid: tantalum pentachloride: the percentage mass ratio of citric acid is 57:38:5, the ethylene glycol of volume ratio 1:1 and n-butanol solution, the concentration of chloroiridic acid is 35g / L .

[0024] Preparation method: The preparation method of the coated electrode: put the titanium plate into 4% sodium carbonate solution, boil for 40 minutes, then rinse it with deionized water, and dry it; then put it into 5% oxalic acid solution and boil for 70 minutes, Take it out, rinse it, and dry it; apply the coating solution on the titanium plate with a brush, dry it at 120°C, and then oxidize it in hot air at 480°C for 15 minutes. After cooling, repeat the above process 15 times, and finally, heat treatment at 480°C After 1.5h, it was cooled to room temperature to obtain an iridium-tantalum-coated titanium electrode.

Embodiment 2

[0025] Embodiment 2: chloroiridic acid: tantalum pentachloride: the percentage mass ratio of tartaric acid is 60:36:4, the ethylene glycol and n-butanol solution of volume ratio 1:1, and the concentration of chloroiridic acid is 35g / L.

[0026] Preparation method: The preparation method of the coated electrode: put the titanium plate into 6% sodium carbonate solution, boil for 30 minutes, then rinse it with deionized water, and dry it; then put it into 5% oxalic acid solution and boil for 60 minutes, Take it out, rinse it, and dry it; apply the coating solution on the titanium plate with a brush, dry it at 130°C, and then oxidize it in hot air at 500°C for 18 minutes. After cooling, repeat the above process 17 times, and finally, heat treatment at 500°C After 1.2h, it was cooled to room temperature to obtain an iridium-tantalum-coated titanium electrode.

Embodiment 3

[0027] Embodiment 3: chloroiridic acid: tantalum pentachloride: the percentage mass ratio of malic acid is 57:38:5, the ethylene glycol and n-butanol solution of volume ratio 1:1, and the concentration of chloroiridic acid is 35g / L .

[0028] Preparation method: The preparation method of the coated electrode: put the titanium plate into a 3% sodium carbonate solution, boil for 20 minutes, then rinse it with deionized water, and dry it; then put it into a 5% oxalic acid solution and boil for 50 minutes, Take it out, rinse it, and dry it; apply the coating solution on the titanium plate with a brush, dry it at 140°C, and then oxidize it in hot air at 510°C for 10 minutes. After cooling, repeat the above process for 18 times, and finally, heat treatment at 510°C After 1h, it was cooled to room temperature to obtain an iridium-tantalum-coated titanium electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com