Fine-grained silver-based electrical contact material and preparation method thereof

An electrical contact material, silver-based technology, applied in the field of fine-grained silver-based electrical contact materials and its preparation, can solve the problems that have not been found in the same or similar reports, and achieve the purpose of avoiding uneven tissue distribution, fine grains, and suppressing crystal grains. The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

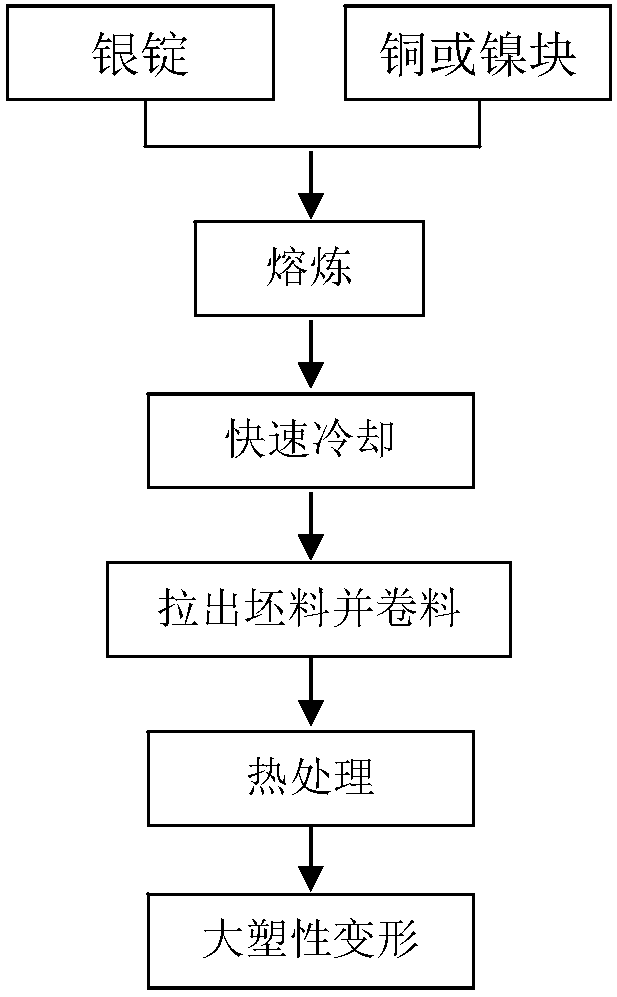

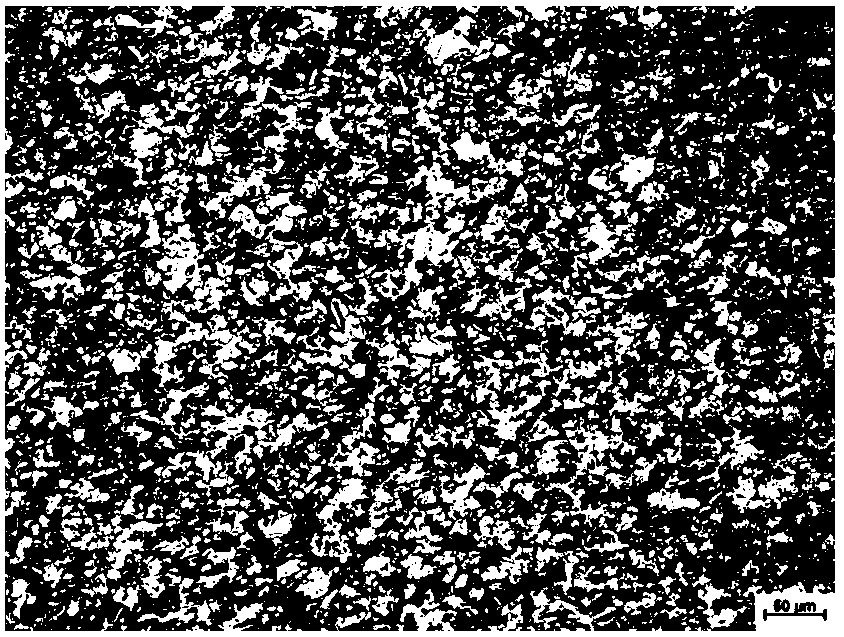

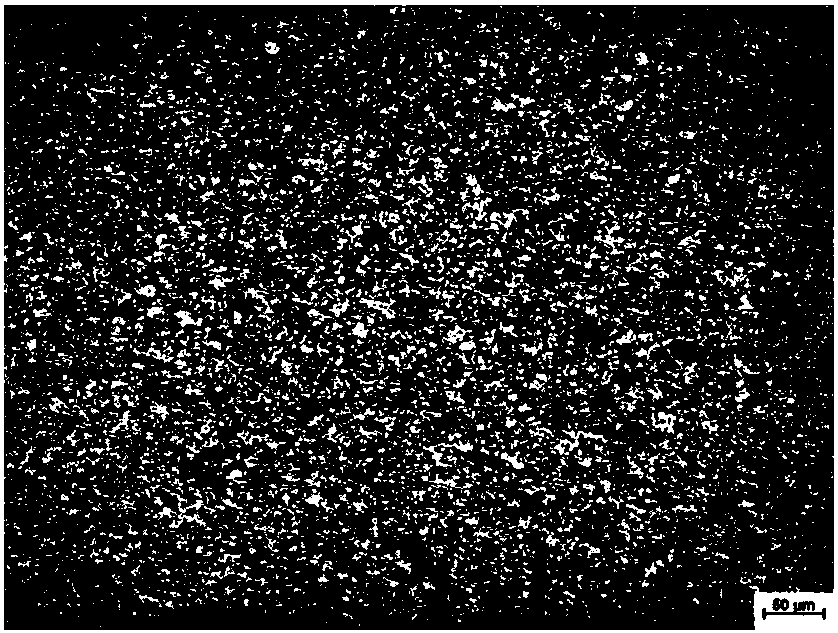

[0032] Taking the preparation of fine-grained AgCu3 electrical contact material as an example

[0033] 1. Weigh 48.5Kg silver ingot, place it in a medium-frequency induction furnace and heat it up to 1100°C to melt, then add 1.5Kg copper block, after 40 minutes of homogenization and heat preservation, a silver-copper metal melt is obtained;

[0034] 2. The molten metal is quickly cooled by the crystallizer on the bottom side of the induction furnace through the water cooling device to form a billet;

[0035] 3. The forming blank is continuously pulled out with a wire rod of Φ12.5mm by the traction device, and the material is collected to form a coil to obtain a silver-copper alloy wire coil;

[0036] 4. Diffusion annealing is carried out on the silver-copper alloy wire, the annealing temperature is 600°C, the time is 2h, and the protective atmosphere is hydrogen, so that the material can be stress-relieved and maintain certain physical and mechanical properties;

[0037] 5. P...

Embodiment 2

[0041] Taking the preparation of fine-grained AgNi0.3 electrical contact material as an example

[0042] 1. Weigh 49.85Kg of silver ingot, put it in a medium frequency induction furnace and heat it up to 1150°C to melt, then add 0.15Kg of nickel block, after 40 minutes of homogenization and heat preservation, the silver-nickel metal melt is obtained;

[0043] 2. The molten metal is quickly cooled by the crystallizer on the bottom side of the induction furnace through the water cooling device to form a billet;

[0044] 3. The forming blank is continuously pulled out with a wire rod of Φ12.5mm by the traction device, and the material is collected to form a coil to obtain a silver-nickel alloy wire coil;

[0045] 4. Diffusion annealing is performed on the silver-nickel alloy wire, the annealing temperature is 500°C, and the time is 2.5h, so that the material can be stress-relieved and maintain certain physical and mechanical properties;

[0046] 5. Perform large plastic deformat...

Embodiment 3

[0050] Taking the preparation of fine-grained AgNi0.15 electrical contact material as an example

[0051] 1. Weigh 49.925Kg of silver ingot, put it in a medium frequency induction furnace and heat it up to 1150°C to melt, then add 0.075Kg of nickel block, after 30 minutes of homogenization and heat preservation, silver-nickel metal melt is obtained;

[0052] 2. The molten metal is quickly cooled by the crystallizer on the bottom side of the induction furnace through the water cooling device to form a billet;

[0053] 3. The forming blank is continuously pulled out with a wire rod of Φ12.5mm by the traction device, and the material is collected to form a coil to obtain a silver-nickel alloy wire coil;

[0054] 4. Diffusion annealing is performed on the silver-nickel alloy wire, the annealing temperature is 460°C, and the time is 3 hours, so that the material can be stress-relieved and maintain certain physical and mechanical properties;

[0055]5. Through multiple extrusion-an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com