Corrosion-resistant aluminum alloy profile and extrusion method thereof

A technology of aluminum alloy profile and extrusion method, which is applied in the field of high toughness and anti-corrosion aluminum alloy profile and its extrusion and high strength, and can solve the problem of single fibrous grain structure of 6005 aluminum alloy profile and the strength of 6005 aluminum alloy profile , Fracture toughness and stress corrosion resistance improvement limit, low strength and other problems, to achieve the effect of inhibiting grain growth, increasing strength and inhibiting recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

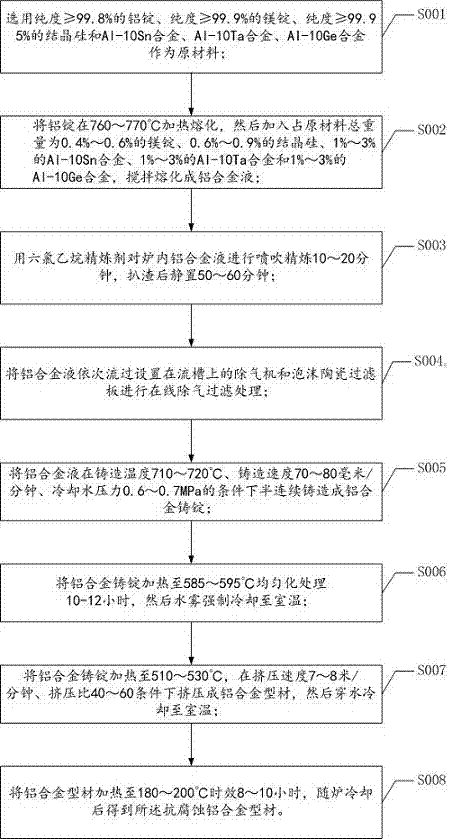

Image

Examples

Embodiment 1

[0058] The composition and mass percentage of the aluminum alloy profile are: Mg 0.4%, Si 0.6%, Sn 0.2%, Ta 0.1%, Ge0.1%, Fe≤0.15%, and the balance is Al.

[0059] The extrusion method of the aluminum alloy profile comprises the following steps:

[0060] Step 1: Select aluminum ingots with a purity of ≥99.8%, magnesium ingots with a purity of ≥99.9%, crystalline silicon with a purity of ≥99.95%, and Al-10Sn alloys, Al-10Ta alloys, and Al-10Ge alloys as raw materials;

[0061] Step 2: Heat and melt the aluminum ingot at 760°C, then add 0.4% magnesium ingot, 0.6% crystalline silicon, 2% Al-10Sn alloy, 1% Al-10Ta alloy and 1% Al-10Ge alloy, stirred and melted into aluminum alloy liquid;

[0062] The third step: use hexachloroethane refining agent to spray and refine the aluminum alloy liquid in the furnace for 10 minutes, and let it stand for 50 minutes after removing the slag;

[0063] Step 4: Flow the aluminum alloy liquid sequentially through a degasser set on the launder wi...

Embodiment 2

[0069] The composition and mass percentage of aluminum alloy profiles are: Mg 0.5%, Si 0.7%, Sn 0.2%, Ta 0.1%, Ge0.3%, Fe≤0.15%, and the balance is Al.

[0070] The extrusion method of the aluminum alloy profile comprises the following steps:

[0071] Step 1: Select aluminum ingots with a purity of ≥99.8%, magnesium ingots with a purity of ≥99.9%, crystalline silicon with a purity of ≥99.95%, and Al-10Sn alloys, Al-10Ta alloys, and Al-10Ge alloys as raw materials;

[0072] Step 2: Heat and melt the aluminum ingot at 770°C, then add 0.5% magnesium ingot, 0.7% crystalline silicon, 2% Al-10Sn alloy, 1% Al-10Ta alloy and 3% Al-10Ge alloy, stirred and melted into aluminum alloy liquid;

[0073] The third step: use hexachloroethane refining agent to spray and refine the aluminum alloy liquid in the furnace for 20 minutes, and let it stand for 50 minutes after removing the slag;

[0074] Step 4: Flow the aluminum alloy liquid sequentially through a degasser set on the launder with ...

Embodiment 3

[0080] The composition and mass percentage of the aluminum alloy profile are: Mg 0.6%, Si 0.9%, Sn 0.3%, Ta 0.1%, Ge0.1%, Fe≤0.15%, and the balance is Al.

[0081] The extrusion method of the aluminum alloy profile comprises the following steps:

[0082] Step 1: Select aluminum ingots with a purity of ≥99.8%, magnesium ingots with a purity of ≥99.9%, crystalline silicon with a purity of ≥99.95%, and Al-10Sn alloys, Al-10Ta alloys, and Al-10Ge alloys as raw materials;

[0083] Step 2: Heat and melt the aluminum ingot at 765°C, then add 0.6% magnesium ingot, 0.9% crystalline silicon, 3% Al-10Sn alloy, 1% Al-10Ta alloy and 1% Al-10Ge alloy, stirred and melted into aluminum alloy liquid;

[0084] The third step: use hexachloroethane refining agent to spray and refine the aluminum alloy liquid in the furnace for 15 minutes, and let it stand for 55 minutes after removing slag;

[0085] Step 4: Flow the aluminum alloy liquid sequentially through a degasser set on the launder with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com