Preparation method of nickel-manganese zinc ferrite material with high impedance and magnetic property

A manganese-zinc ferrite, high magnetic technology, applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc., can solve the problems that manganese-zinc ferrite materials cannot achieve good application effects in medium and high frequencies , to enhance the mechanical properties, expand the scope of application, and improve the oxygen content distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of high impedance high magnetic performance nickel-manganese zinc ferrite material of the present invention comprises the following steps:

[0026] S1, will contain Ni 2+ , Zn 2+ , Mn 2+ , Fe 2+ The metal salt is made into a metal nitrate solution to obtain a mixed solution A, and then the alkali solution of graphene is added to the mixed solution A, and ethylenediaminetetraacetic acid and titanate coupling agent are added under magnetic stirring, and ammonia water is added dropwise Adjust the pH to 4-6, heat to 80-100°C, react for 1-2 hours, and let stand for 3-5 hours; filter, wash and dry to obtain the first material,

[0027] S2, after adding ferrocene magnetic powder, polyvinyl alcohol (PVA) and bisphenol A epoxy resin to the first material and mixing, ball milling to obtain the second material;

[0028] S3. After pressing the third material into shape, microwave sintering and cooling are performed to obtain a manganese zinc ferrite...

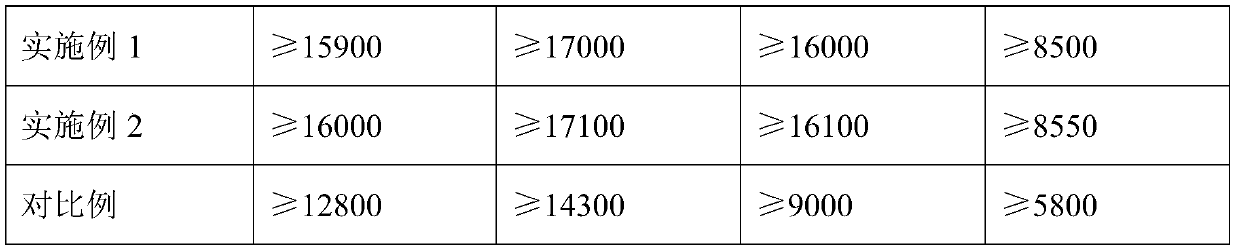

example 1

[0030] (1) According to the chemical formula NiMnZnFe 2 o 4 , the Mn(NO 3 ) 2 , Fe(NO 3 ) 3 .9H 2 O, Zn(NO 3 ) 2 .6H 2 O is made into a 0.2mol / L aqueous solution under strong stirring according to the chemical dosage ratio to obtain a mixed solution A;

[0031] (2) the preparation of the alkali solution of graphene, take a certain amount of graphene and NaOH solution to mix and ultrasonic vibration 30 minutes and be made into the alkali solution of graphene; The mass ratio of NaOH and graphene is 1: 1;

[0032] (3) At 25°C, add the alkali solution of graphene into the mixed solution A, add ethylenediaminetetraacetic acid and titanate coupling agent under magnetic stirring, and drop ammonia water to adjust the pH to 4-6, and the mixed solution The volume ratio of A to the alkali solution of graphene is 35:1; the sol is allowed to stand for 5 minutes to obtain a gel. The obtained gel was placed in a drying oven, and dried at 200° C. for about 1.5 h to obtain a block-sh...

example 2

[0037] (1) According to the chemical formula Ni-MnZnFe 2 o4 , the Ni(NO 3 ) 2 , Mn(NO 3 ) 2 , Fe(NO 3 ) 3 .9H 2 O, Zn(NO 3 ) 2 .6H 2 O is made into a 0.2mol / L aqueous solution under strong stirring according to the chemical dosage ratio to obtain a mixed solution A;

[0038] (2) the preparation of the alkali solution of graphene, take a certain amount of graphene and NaOH solution to mix and ultrasonic vibration 30 minutes and be made into the alkali solution of graphene; The mass ratio of NaOH and graphene is 2:1;

[0039] (3) At 25°C, add the alkali solution of graphene into the mixed solution A, add ethylenediaminetetraacetic acid and titanate coupling agent under magnetic stirring, and drop ammonia water to adjust the pH to 4-6, and the mixed solution The volume ratio of A to the alkali solution of graphene is 35:1; the sol is allowed to stand for 5 minutes to obtain a gel. The obtained gel was placed in a drying oven, and dried at 200° C. for about 1.5 h to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com