High-hardness cobalt-based alloy powder for laser cladding and preparation technology of high-hardness cobalt-based alloy powder for laser cladding

A cobalt-based alloy, laser cladding technology, applied in the field of metal surface hardening treatment, can solve problems such as cracking, poor self-fluxing, and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

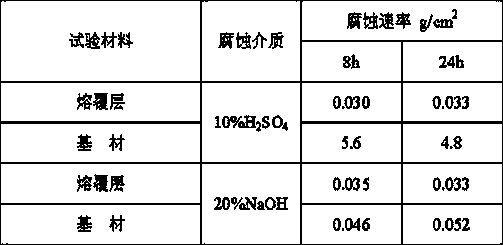

Embodiment 1

[0016] 1. Test material: the base material is ASTMA182F304.

[0017] 2. Laser cladding materials:

[0018] The composition is (by weight): C: 1.2%; Cr: 28%; Fe: 3%; Mn: 0.04%; Mo: 1%; Ni: 3%; Si: 0.7%; W: 3.5%; Co.

[0019] 3. Melt the prepared ingredients, and the smelting is carried out under the condition of vacuum degree of 1Pa.

[0020] The temperature is 1800°C, and the melting mass of each furnace is 50KG. The smelted ingredients are subjected to slagging and deoxidation treatment, and then the ingredients are made into powder by the atomization pulverization method. In this process, nitrogen is used as the atomization medium, atomized for 5 minutes under 8Pa atmospheric pressure, and then in the absence of oxygen or Cooling is carried out in a low-oxygen state, and finally sieved to obtain high-hardness cobalt-based alloy powder.

[0021] 4. The laser cladding process adopts a laser cladding machine with a power of 3km and a speed of 5mm / s.

[0022] The diameter o...

Embodiment 2

[0032] 1. Test material: the base material is ASTMA182F304.

[0033] 2. Laser cladding materials:

[0034] The composition is (by weight): C: 1.55%; Cr: 31%; Fe: 3%; Mn: 0.05%; Mo: 2%; Ni: 4%; Si: 1.5%; W: 6.5%; Co.

[0035] 3. Smelting the prepared ingredients, the smelting is carried out under the condition of vacuum degree of 10Pa, the temperature is 2700°C, and the melting mass of each furnace is 50KG. The smelted ingredients are subjected to slagging and deoxidation treatment, and then the ingredients are made into powder by the atomization pulverization method. In this process, nitrogen is used as the atomization medium, atomized for 8 minutes under 10Pa atmospheric pressure, and then the powder is sprayed in an oxygen-free or Cooling is carried out in a low-oxygen state, and finally sieved to obtain high-hardness cobalt-based alloy powder.

[0036] 4. Laser cladding process, using a laser cladding machine, the power is 4km, the speed is 10mm / s, the spot diameter is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com