Defrosting system of air-cooled refrigerator, control method for defrosting system and air-cooled refrigerator

An air-cooled refrigerator and control method technology, which is applied in defrosting, household refrigeration devices, cooling fluid circulation devices, etc., can solve the problems of long defrosting heating time, long defrosting time, uneven defrosting, etc., and achieve resource saving And energy, defrosting effect is good, the effect of completely melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

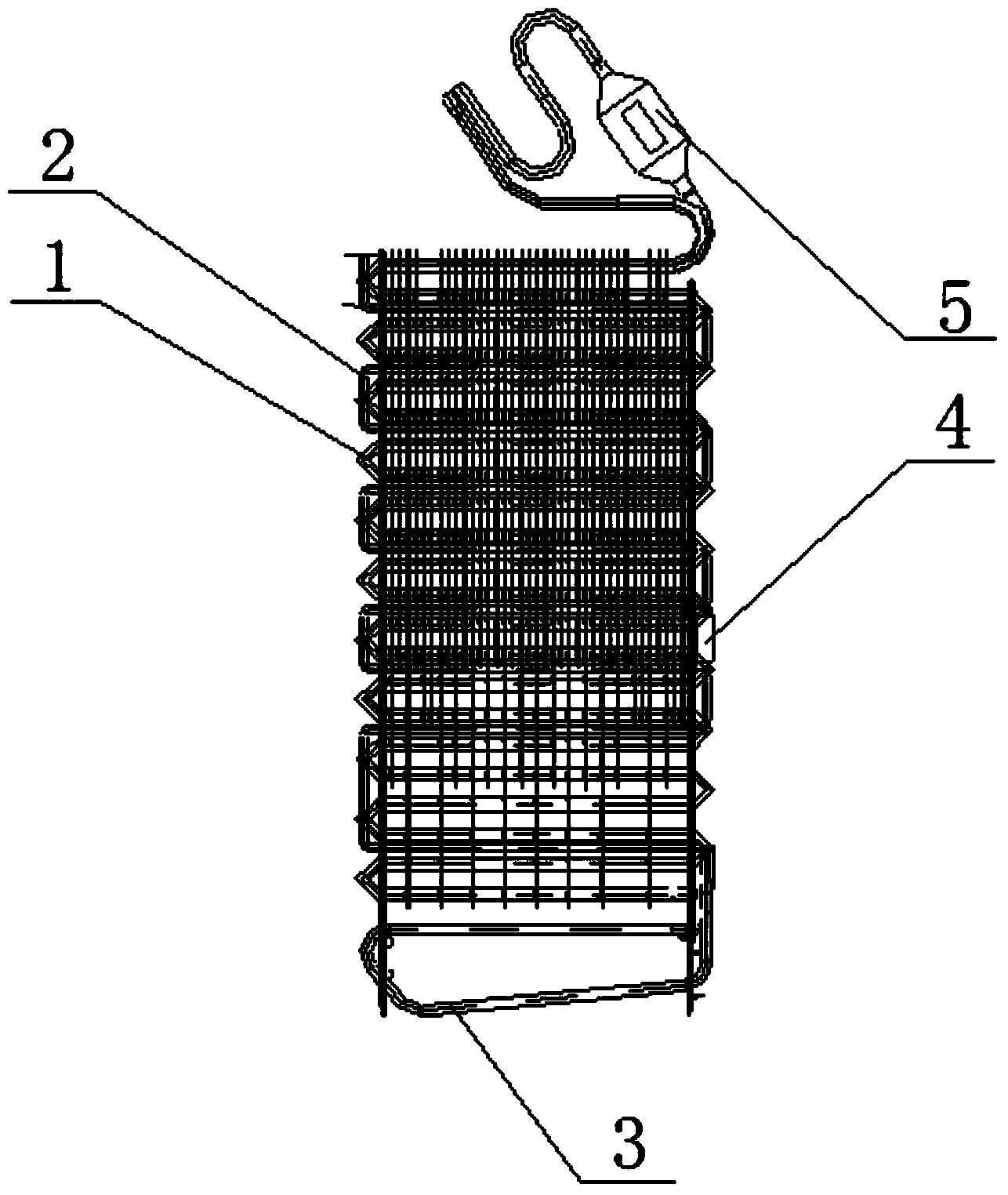

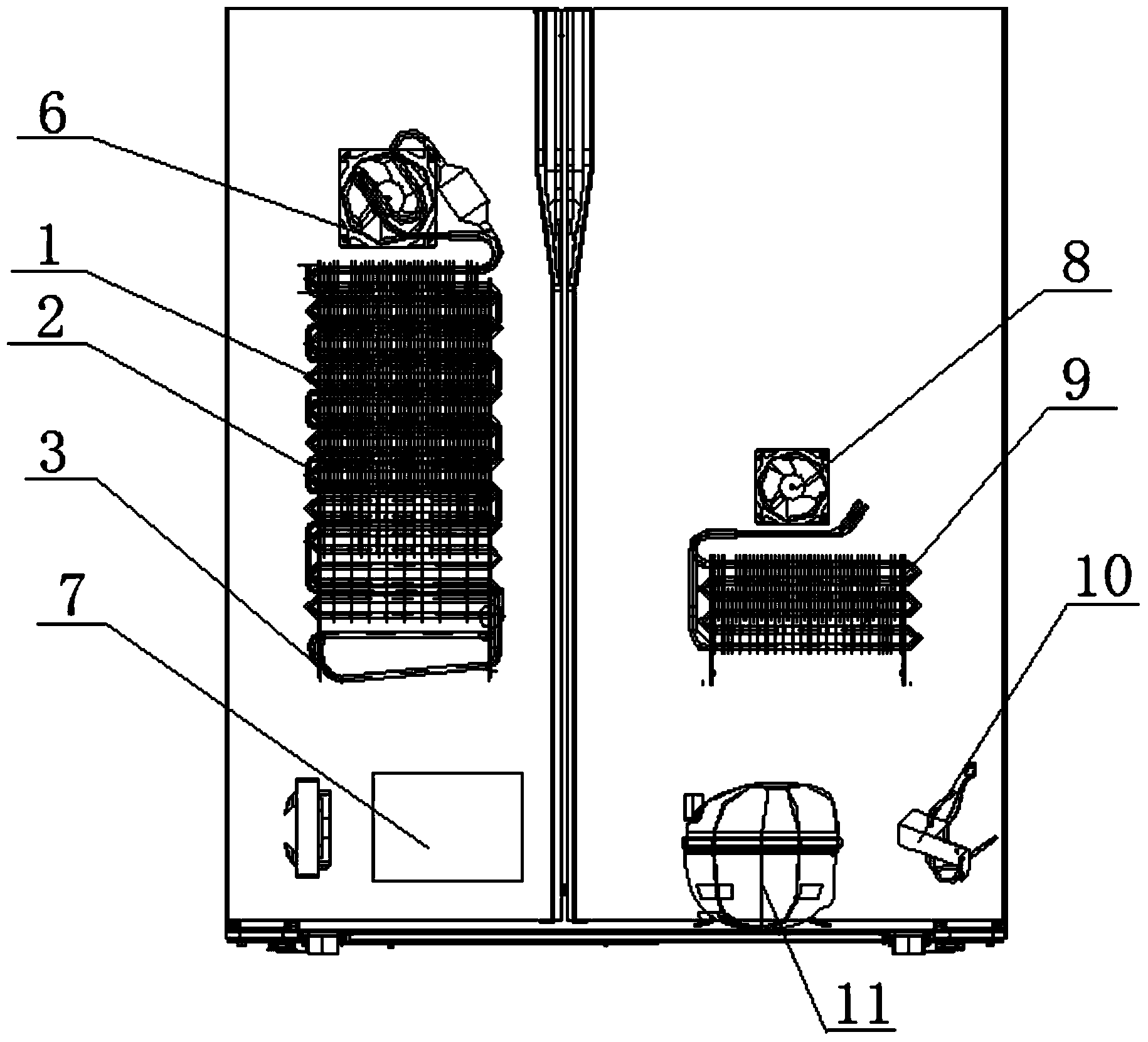

[0033] Such as figure 1 , combined with figure 2 Shown is the structure of the freezer evaporator part of the air-cooled refrigerator defrosting system proposed in this embodiment, including the freezer evaporator 1, and the freezer evaporator 1 is provided with a freezer defrosting assembly. The freezer defrosting assembly is used to heat and defrost the evaporator 1 in the freezer of the air-cooled refrigerator when the air-cooled refrigerator is defrosting. As a further embodiment, the defrosting assembly for the freezing chamber includes a first defrosting component 3 arranged below the bottom of the freezing chamber evaporator 1 and a second defrosting component 3 arranged on the side wall of the freezing chamber evaporator 1 . Frost part2. In this embodiment, the freezer defrosting assembly only includes the first defrosting part 3 and the second defrosting part 2, but in the actual implementation process, it is not limited to only including the above two defrosting p...

Embodiment 2

[0043] This embodiment discloses a method for controlling the defrosting system of an air-cooled refrigerator, which is used for controlling the defrosting system of an air-cooled refrigerator as described in Embodiment 1. The specific control method is: when the air-cooled refrigerator enters the defrosting stage, the circuit control board controls the controller to turn on the first defrosting part and the second defrosting part in sequence.

[0044] As a further control scheme, the program is pre-written in the circuit control board, so that the temperature rise rate of the second defrosting part from the start to greater than or equal to the first predetermined temperature is V1, and the first defrosting part is from The speed of temperature rise during the process of turning on to be greater than or equal to the second predetermined temperature is V2, and it is ensured that the speed V1 is less than the speed V2 during the temperature rise process.

[0045] When the tempe...

Embodiment 3

[0051] Such as figure 2 Shown is an air-cooled refrigerator proposed in this embodiment, and the air-cooled refrigerator is provided with the defrosting system of the air-cooled refrigerator as described in Embodiment 1. In addition to being provided with the defrosting system of the air-cooled refrigerator in Embodiment 1, the air-cooled refrigerator is also provided with a freezer fan 6 for delivering cold air from the freezer to the freezer, and a refrigerating room that delivers cold air from the refrigerator to the refrigerating room. Fan 8, condenser 7, solenoid valve 10 and compressor 11.

[0052] When the temperatures in both the refrigerator compartment and the freezer compartment are greater than the set temperature value, the compressor 11 starts, and the freezer compartment evaporator 1 and the refrigerator compartment evaporator 9 start to refrigerate. After the refrigeration started, the freezer fan 6 and the refrigerating room fan 8 started to run, and at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com