Powdery polyether-ether-ketone material sideways feeding type 3D printer

A 3D printer, polyether ether ketone technology, applied in the field of 3D printing, can solve the problems of easy cooling of plastic fibers, low feeding efficiency, affecting use efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

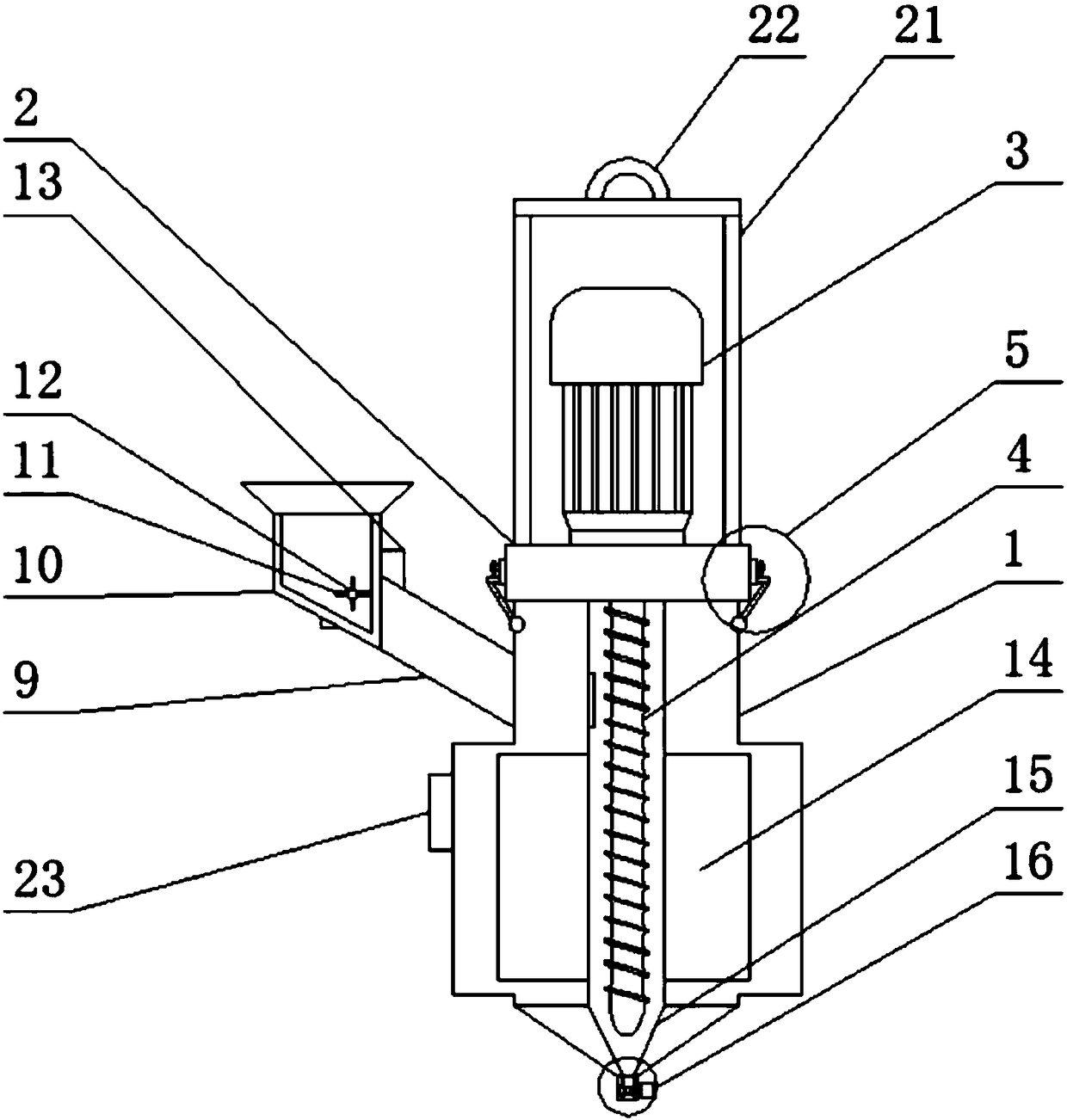

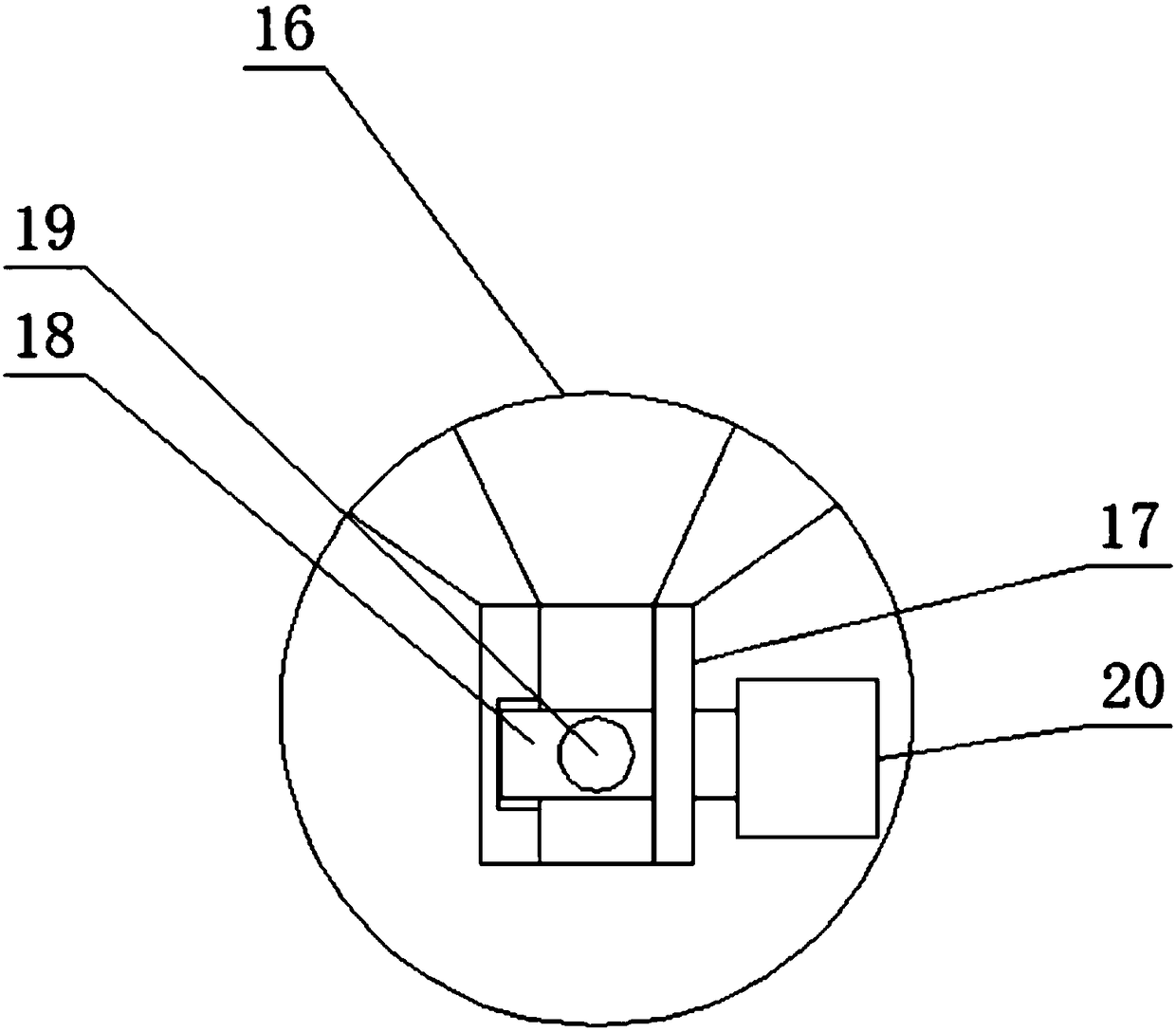

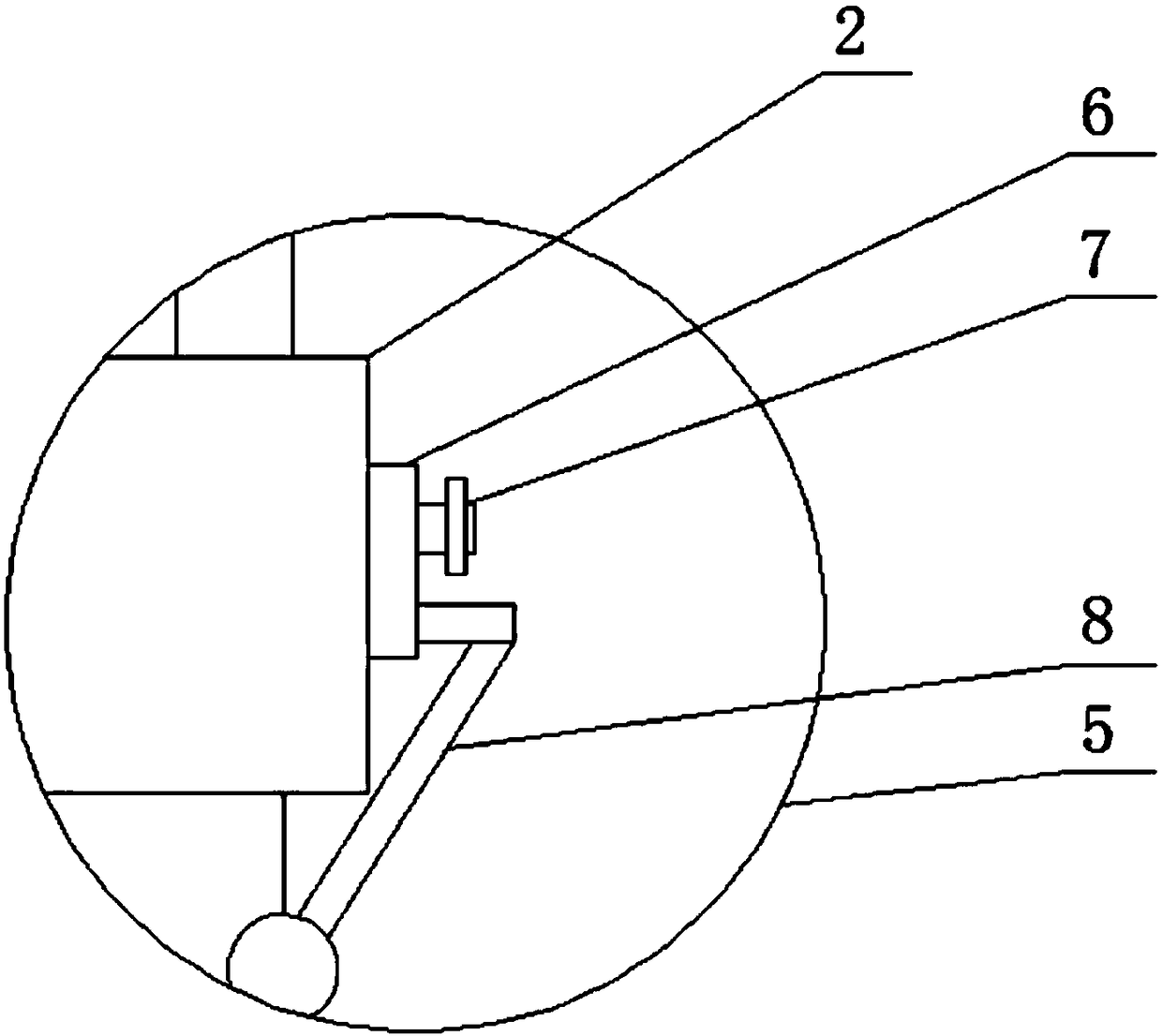

[0019] The present invention provides such as Figure 1-3 A side-feeding 3D printer of powder polyetheretherketone material as shown includes a housing 1, a fixed cover 2 is provided on the top of the housing 1, a first motor 3 is provided on the top of the fixed cover 2, and the The bottom of the fixed cover 2 is provided with a screw rod 4, and both sides of the fixed cover 2 are provided with a fixing device 5. By setting the fixing device 5, when the inside of the shell 1 needs to be cleaned, the bolt 7 is opened, and then the fixing device 5 is fixed by the hook 22. The cover 2, the first motor 3 and the screw rod 4 are disassembled, which is beneficial to cleaning the inside of the housing 1. The fixing device 5 includes a fixing plate 6, and the surface of the fixing plate 6 is provided with a bolt 7, and the fixing plate 6 is passed through the bolt. 7 is fixedly connected with the fixed cover 2, one side of the fixed cover 2 is provided with a fixed rod 8, one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com