Bottom-blowing pure oxygen enhanced type plasma gasification melting furnace

A gasification melting, enhanced technology, applied in the direction of incinerator, indirect carbon dioxide emission reduction, combustion type, etc., can solve the problems of uneven distribution of temperature field, increase of equipment cost, extremely high power, etc., and achieve reduction of flue gas emissions , The effect of increasing the furnace temperature and reducing the loss of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

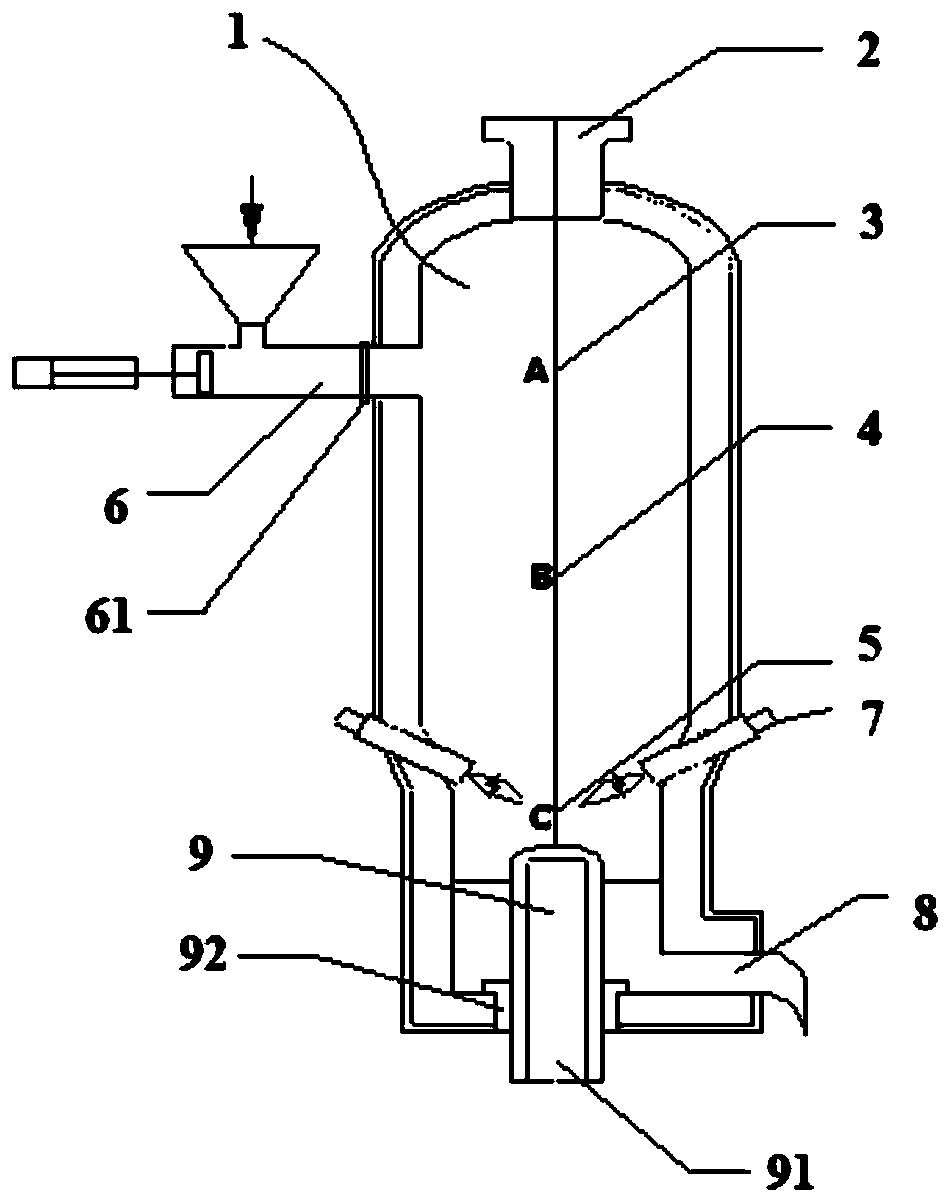

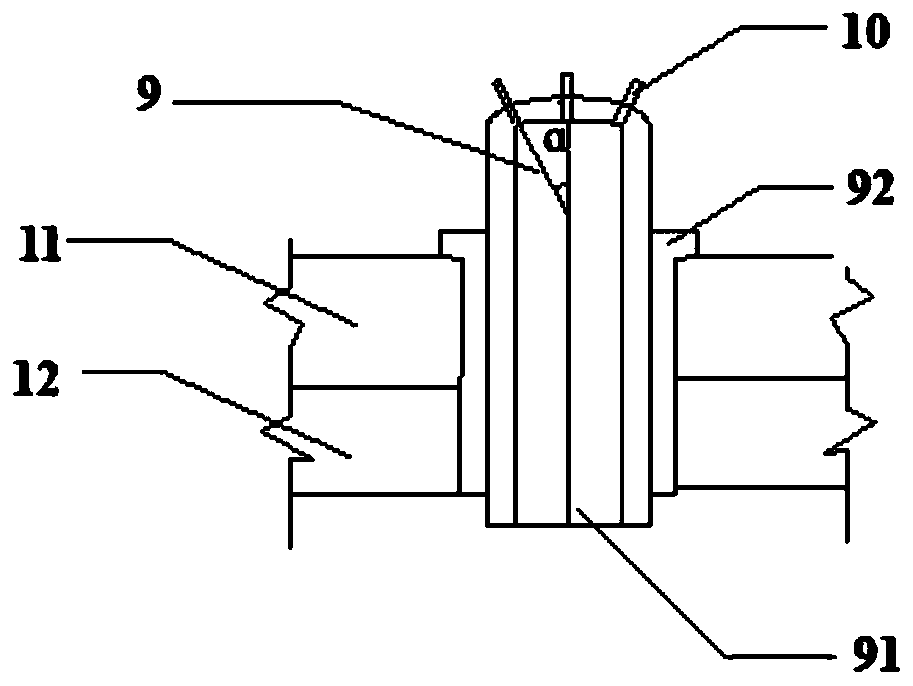

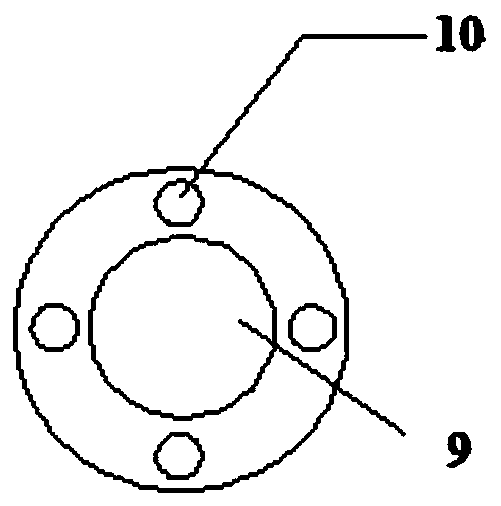

[0027] like figure 1 As shown, the present invention provides a bottom-blown pure oxygen enhanced plasma gasification melting furnace, including a furnace body 1, and the furnace body 1 is sequentially composed of a synthesis gas outlet 2, an upper furnace hearth 3, a middle furnace hearth 4 and a lower furnace hearth. 5; the diameter of the lower furnace 5 is smaller than that of the upper furnace 3, and the middle furnace 4 and the lower furnace 5 are connected by a tapered neck section; the side wall of the upper furnace 3 is provided with a hazardous waste material inlet 6; on the side of the lower furnace 5 The wall is provided with a plasma torch 7 inclined downward in the lower furnace 5, and a slagging outlet 8 is also provided on the lower side wall of the lower furnace 5; The cylindrical central oxygen supply pipe 9 at the bottom of body 1 is closed at the top and open at the bottom; The outlets 10 are evenly distributed on the upper part of the central oxygen suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com