Preparation process of Pb-Ca-Sn-Al alloy

A calcium-aluminum alloy and aluminum alloy technology, which is applied in the preparation process of lead-calcium-tin-aluminum alloy, can solve problems such as uneven stirring, difficult control of calcium content, and calcium oxidation, so as to reduce fuel consumption and reduce cooling waiting time , Reduce the effect of oxidation and burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

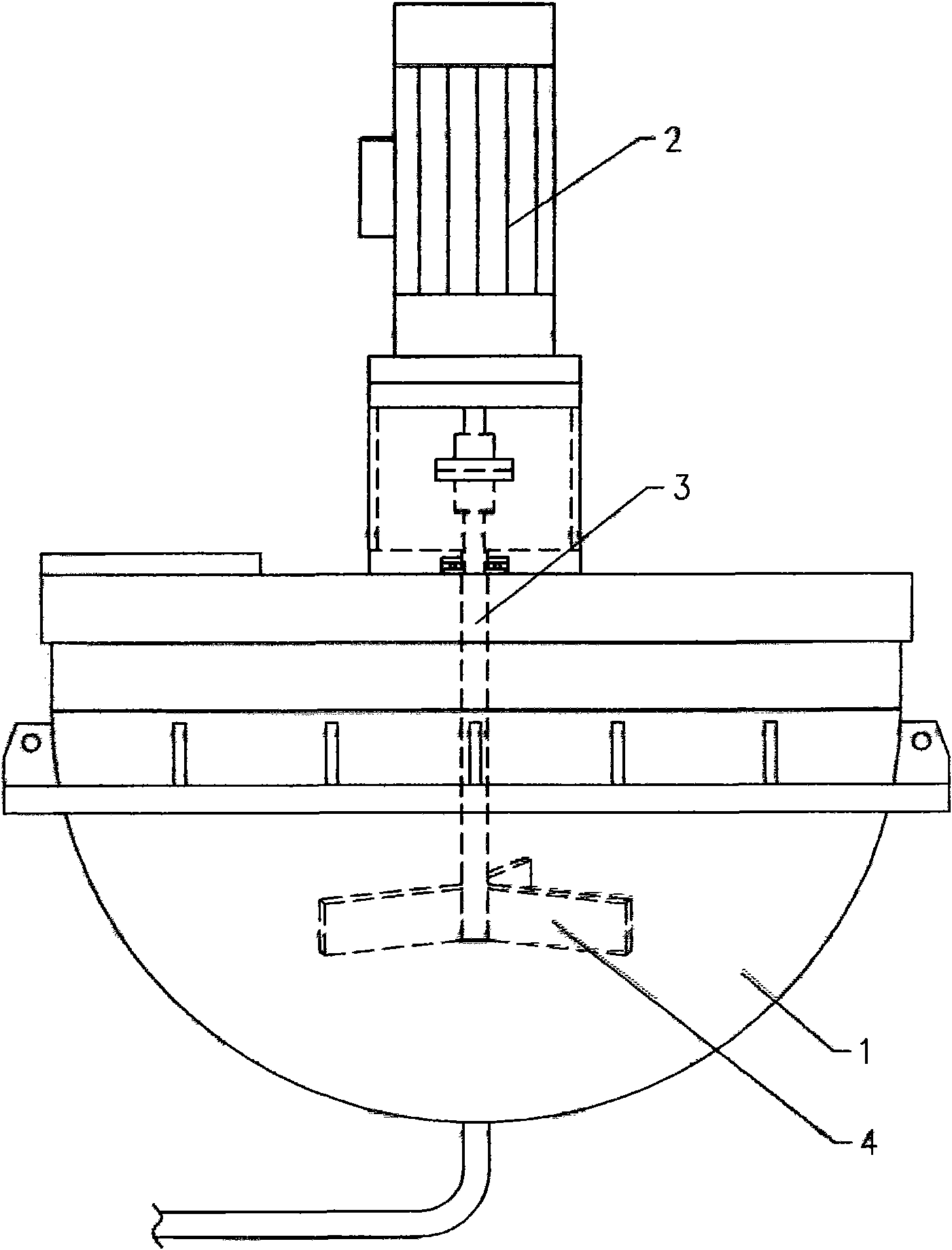

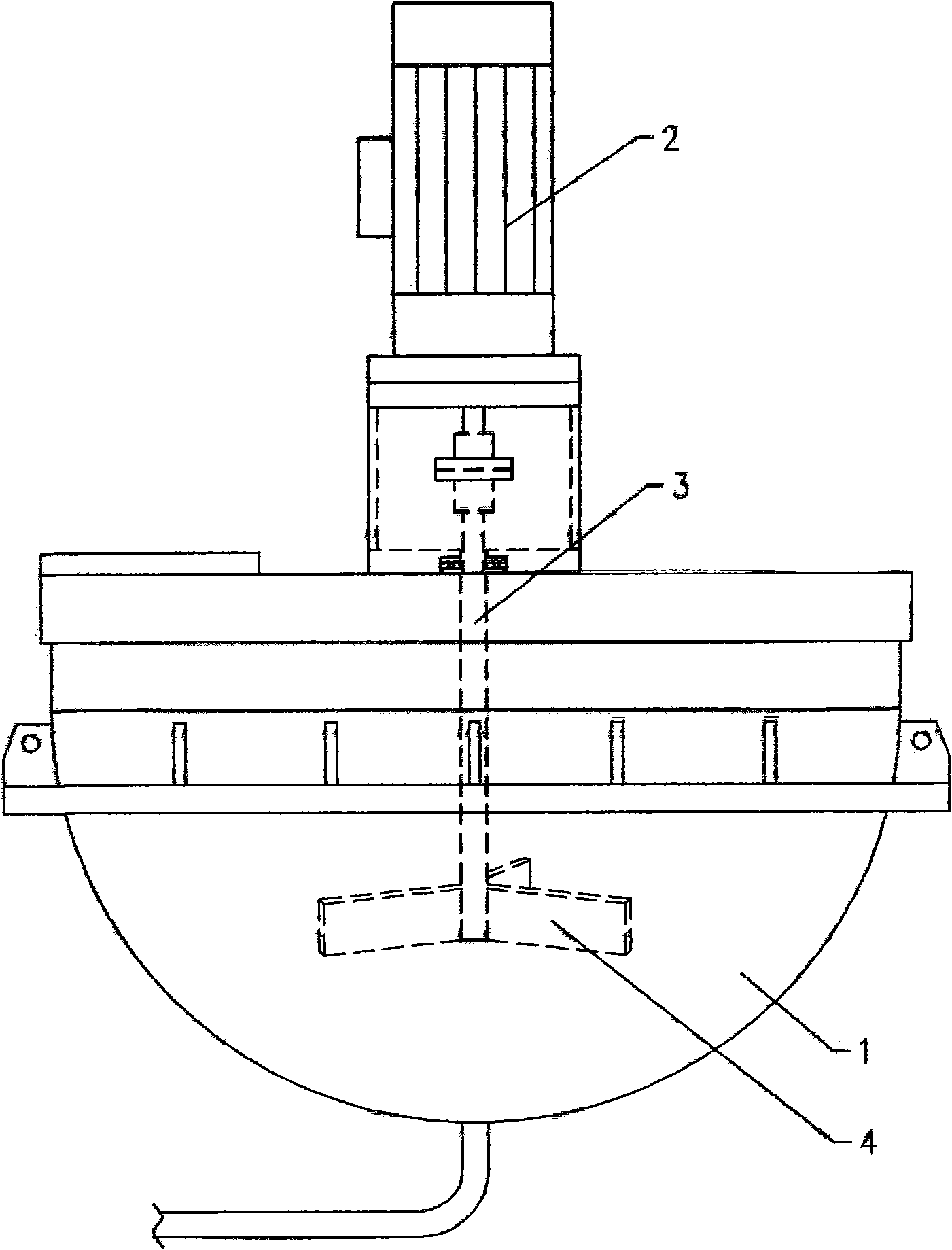

Image

Examples

Embodiment 1

[0032] A preparation process of lead-calcium-tin-aluminum alloy, which comprises the following steps:

[0033] (1) Prepare raw materials: lead, tin and calcium aluminum alloy, and each raw material accounts for the weight percent of total raw material as:

[0034] Lead 99.25%

[0035] Tin 0.6%

[0036] Calcium aluminum alloy 0.15%,

[0037] Wherein, the weight ratio of calcium to aluminum in the calcium aluminum alloy is 3:2;

[0038] (2) Add 70% of the lead material to the lead melting pot, heat to 670°C to fully melt the lead, stir the lead melt for about 2 to 3 minutes, and pour into the lead in the stirring state. Add calcium-aluminum alloy to the melt, and continue to stir for 2 minutes, so that the calcium-aluminum alloy is completely melted and mixed evenly;

[0039] (3) Stop stirring and heating, add the remaining lead into the lead melting pot, after the remaining lead is melted, stir the mixed melt, add tin to the mixed melt under stirring state, and continue to ...

Embodiment 2

[0044] A preparation process of lead-calcium-tin-aluminum alloy, which comprises the following steps:

[0045] (1) Prepare raw materials: lead, tin and calcium aluminum alloy, and each raw material accounts for the weight percent of total raw material as:

[0046] Lead 99.35%

[0047] Tin 0.5%

[0048] Calcium aluminum alloy 0.15%,

[0049] Wherein, the weight ratio of calcium to aluminum in the calcium aluminum alloy is 2:1;

[0050] (2) Add 75% of the lead material to the lead melting pot, heat it to 700°C to fully melt the lead ingot, stir the lead melt for about 2 to 3 minutes, and pour it under the stirring state. Add calcium-aluminum alloy to the lead melt, and continue to stir for 2 minutes to completely melt the calcium-aluminum alloy and mix evenly;

[0051] (3) Stop stirring and heating, add the remaining lead in the lead melting pot, after the remaining lead is melted, stir the mixed molten solution, add tin to the mixed molten solution under the stirring state,...

Embodiment 3

[0056] A preparation process of lead-calcium-tin-aluminum alloy, which comprises the following steps:

[0057] (1) Prepare raw materials: lead, tin and calcium aluminum alloy, and each raw material accounts for the weight percent of total raw material as:

[0058] Lead 99.45%

[0059] Tin 0.45%

[0060] Calcium aluminum alloy 0.1%,

[0061] Wherein, the weight ratio of calcium to aluminum in calcium aluminum alloy is 5:2;

[0062] (2) Add 80% of lead, which accounts for 80% of the total weight of the lead raw material, into the lead melting pot, heat to 700°C to fully melt the lead, stir the lead melt for about 2 to 3 minutes, and pour into the lead in the stirring state. Add calcium-aluminum alloy to the melt, and continue to stir for 2 minutes, so that the calcium-aluminum alloy is completely melted and mixed evenly;

[0063] (3) Stop stirring and heating, add the remaining lead in the lead melting pot, after the remaining lead is melted, stir the mixed molten solution, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com