Medium-carbon vanadium-containing alloy steel for drill rod and preparation method thereof

A technology of alloy steel and drill rod, which is applied in the field of alloy structural steel, and can solve problems such as wear resistance, poor high-temperature durable strength, and short service life of drill rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

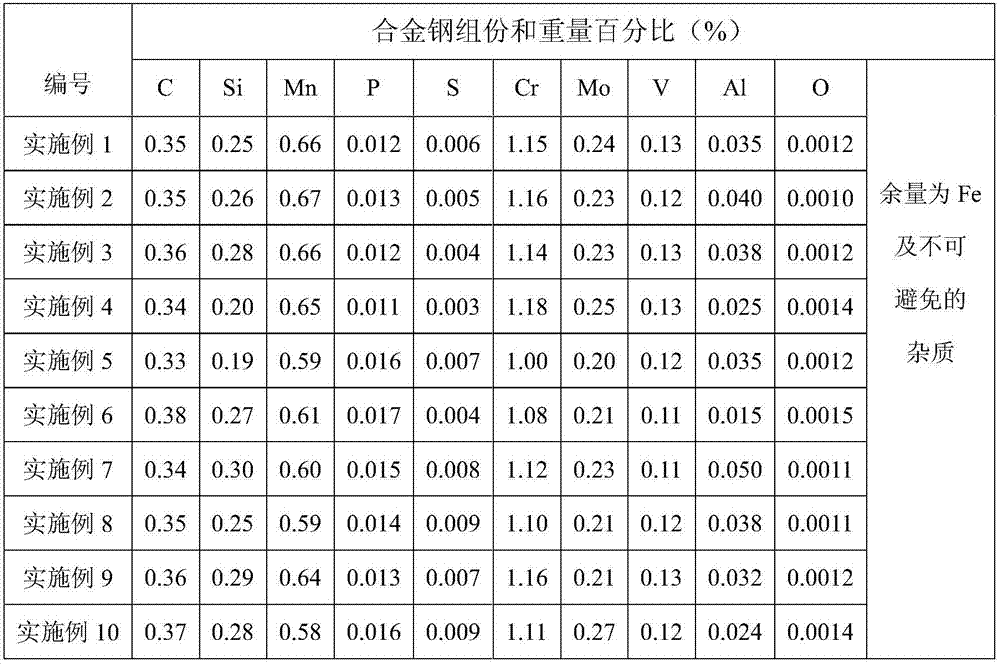

Examples

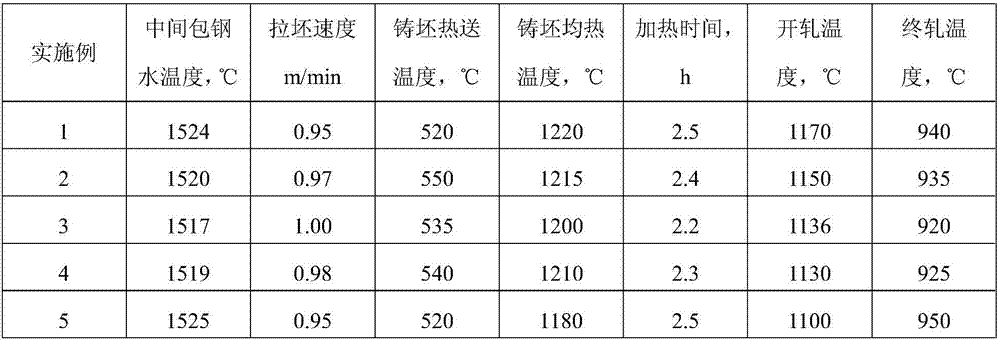

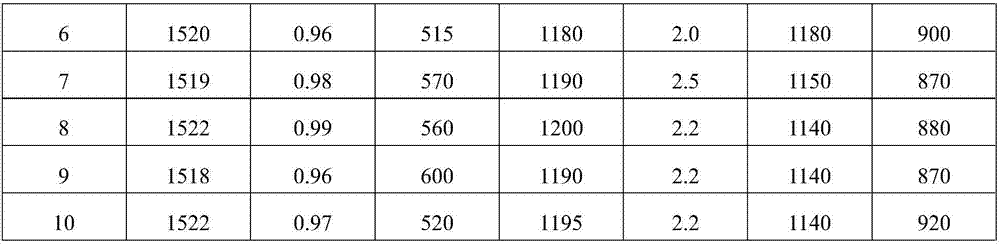

Embodiment 1

[0049] A kind of preparation method of medium-carbon vanadium-containing alloy steel for drill rod comprises the following steps:

[0050] 1) Electric furnace smelting: The raw materials for the furnace are molten iron and scrap steel, and alloys such as silicomanganese, high manganese, high chromium, and ferromolybdenum are added according to the specified composition ratio for ladle alloying. The proportion of molten iron is 68.8%; the scrap steel added is of high quality Scrap steel and added alloys are baked to reduce the substitution of nitrogen, hydrogen and other gases;

[0051] During the smelting process of the electric furnace, foam slag is made to uniformly decarburize, reduce nitrogen absorption, control the tapping end point of the electric furnace to be 0.13%, and P to be 0.008%. The content of residual elements meets the design requirements, and the tapping temperature of molten steel is controlled at 1630°C; Add steel core aluminum 2.0kg / t steel and slagging ma...

Embodiment 2

[0058] A kind of preparation method of medium-carbon vanadium-containing alloy steel for drill rod comprises the following steps:

[0059] 1) Electric furnace smelting: The raw materials into the furnace are molten iron and scrap steel, and alloys such as silicomanganese, high manganese, high chromium, and ferromolybdenum are added according to the specified composition ratio for ladle alloying. The proportion of molten iron is 71%; the added scrap steel is High-quality steel scrap, the added alloys are baked to reduce the substitution of nitrogen, hydrogen and other gases;

[0060]In the electric furnace smelting process, the foamed slag is made to uniformly decarburize, reduce nitrogen absorption, control the tapping end of the electric furnace to 0.15%, P to 0.007%, the content of residual elements meets the design requirements, and the tapping temperature of molten steel is controlled at 1650°C; During the steel process, 2.2kg / t of steel core aluminum and 11kg / t of slag-fo...

Embodiment 3

[0067] A kind of preparation method of medium-carbon vanadium-containing alloy steel for drill rod comprises the following steps:

[0068] 1) Electric furnace smelting: The raw materials into the furnace are molten iron and steel scrap, and alloys such as silicomanganese, high manganese, high chromium, and ferromolybdenum are added according to the specified composition ratio for ladle alloying. The proportion of molten iron is 70%; the added scrap steel is of high quality Scrap steel and added alloys are baked to reduce the substitution of nitrogen, hydrogen and other gases;

[0069] During the smelting process of the electric furnace, foam slag is produced to uniformly decarburize, reduce nitrogen absorption, control the end point C of electric furnace tapping to 0.16%, and P to 0.007%. The content of residual elements meets the design requirements, and the tapping temperature of molten steel is controlled at 1635°C; Add steel core aluminum 2.2kg / t steel and slagging materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com