Multi-component hot spraying flexible wire and preparation method thereof

A flexible wire, thermal spraying technology, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems that affect the continuous spraying process, difficult to control the diameter uniformity of flexible wire, etc., and achieve good wearability , Excellent thermal shock resistance, easy to control the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

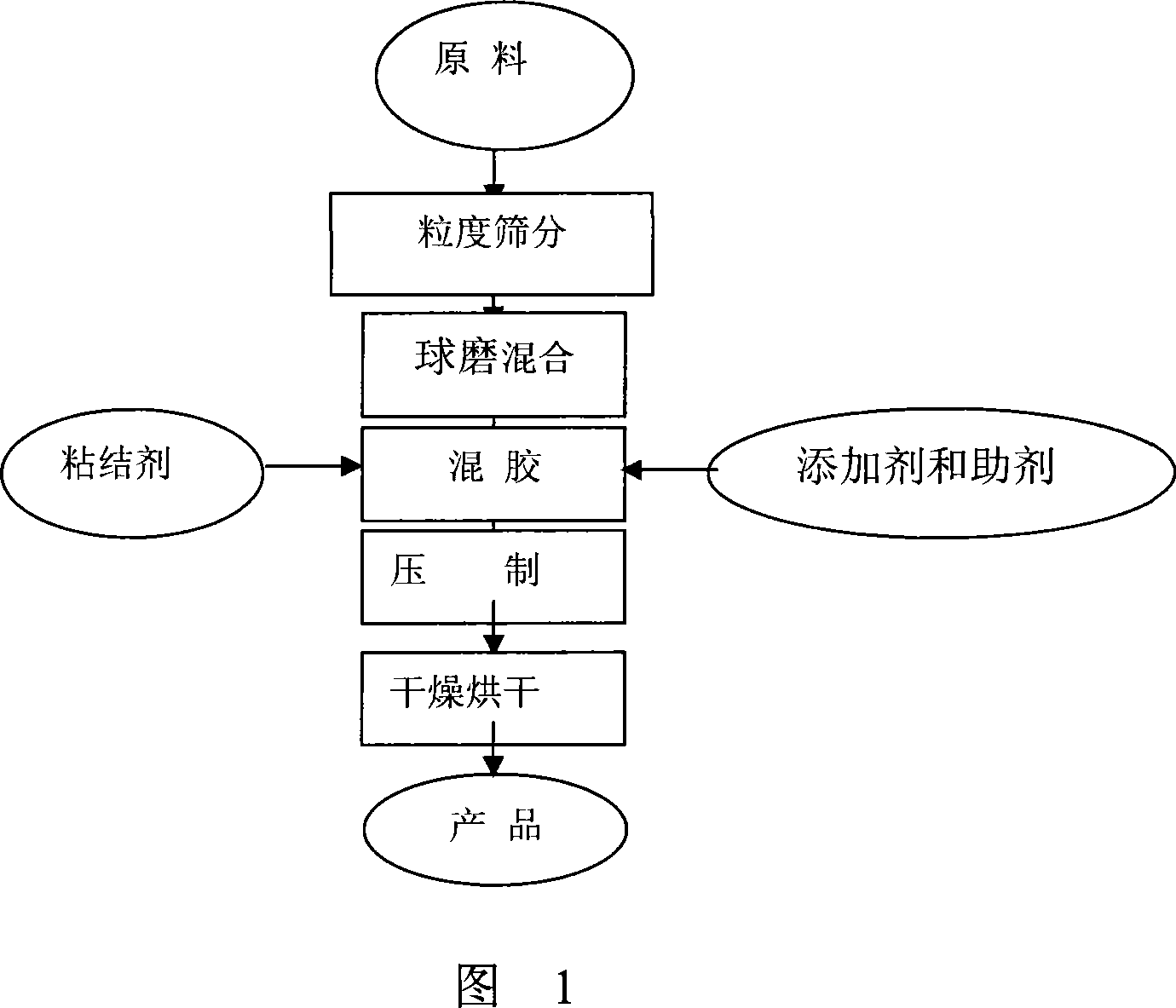

Embodiment 1

[0026] Using Ni, Al, Cr, W, Co, Mo, Ti, Cu, and C as raw materials, the various components are Al, 20%; Cr, 1.0%; W, 3.0%; Co, 0.1%; Mo, 2.0% %; Ti, 1.5%, Cu, 5.0%; C, 5.0%, Ni, the balance, mixed evenly according to a certain proportion, adding organic binders such as sodium butyl glue, curing agent and auxiliary agent, the ratio of the binder is 15.0% of the powder is pressed on a speed-adjustable hydraulic press with a pressing speed of 3m / min. The pressing process can be carried out continuously or intermittently, and the forming is dried. Accompanying drawing 1 is the flow chart of processing process.

[0027] The same effect can be achieved if other organic substances such as silicone rubber and epoxy resin are used instead of sodium buna glue.

Embodiment 2

[0029]Ni, Al, W alloy powder is used as raw material according to a certain ratio, wherein the composition of the alloy powder is: Al, 23.0%; W, 3.0%; Ni, the balance. Mix the above-mentioned various raw materials, evenly add silicone rubber as a binder, titanate as a coupling agent and Si oxide as a reinforcing agent, or add organic solvent acetone and then mix (or stir and mix at the same time), The binder ratio is 20.0% of the powder, and the ratios are weight ratios.

[0030] Adding powder containing Cr, Mo, Co, Ti and other elements to the above materials, Cr, 0.1-5.0%; Co, 0.1-5.0%; Mo, 0.1-5.0%; Ti, 0.1-2.0%, will not change the material performance, the same effect can be obtained.

Embodiment 3

[0032] Use Ni, Cu elemental powder or alloy, C elemental powder Si oxide or other salts, and BN as raw materials, and mix them by mechanical ball milling according to a certain proportion, of which C, 5.0-15.0%; Cu, 5.0-25%; BN, 10.0- 16.0%; Si, 0.1-10.0%, mainly Ni. After mixing evenly, add an organic binder, press on a speed-adjustable hydraulic press, and dry after forming to obtain a flexible wire.

[0033] Flame spraying sealing coating, under certain spraying parameter conditions, superalloy as the base material, the experiment shows that the hardness of the coating is moderate, there is no crack on the coating surface, and it has good wearability, friction reduction and resistance Wear resistance, salt spray corrosion resistance, high tensile strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com