Method for preparing Al0.5CoCrFeNi high-entropy alloy

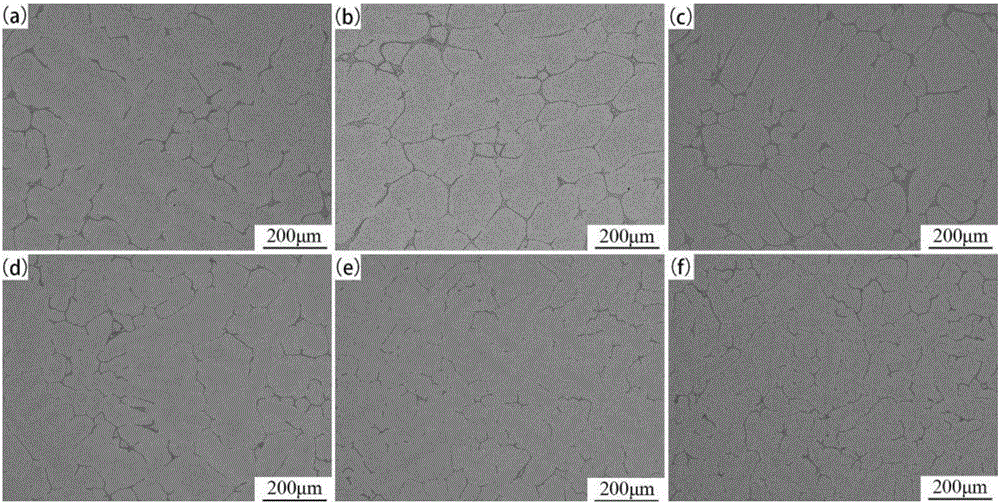

A technology of high-entropy alloys and master alloys, which is applied in the field of preparation of high-entropy alloy materials, can solve the problems of inability to prepare large-volume high-entropy alloys, and achieve the effects of similar grain size, reduced volatilization, and guaranteed composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

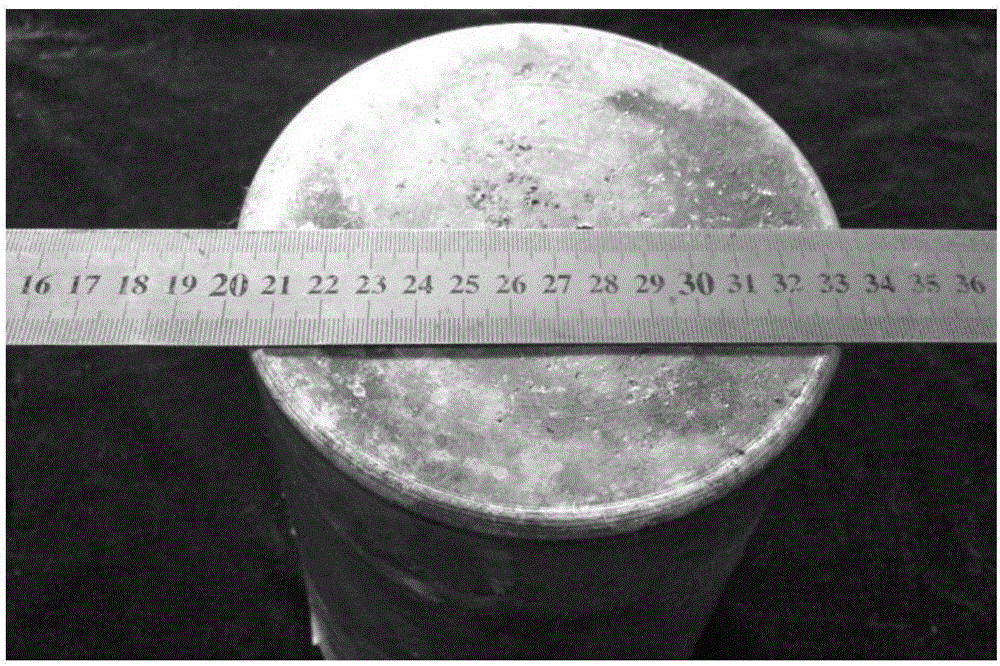

[0030] This embodiment is a kind of FeCoCr and Ni that adopt master alloy 2 Al as raw material to prepare Al 0.5 CoCrFeNi high-entropy alloy method, the Al 0.5 The atomic molar ratio of CoCrFeNi high-entropy alloy is Al 0.5 CoCrFeNi.

[0031] The specific implementation steps are as follows:

[0032] Step 1, surface treatment: for FeCoCr and Ni 2 Al surface grinding treatment. Specifically, bulk FeCoCr with a purity of 99.9wt.% and bulk Ni with a purity of 99.9wt.% 2 Al surface is polished clean. The polished FeCoCr and Ni 2 Al is placed in the acetone solution and ultrasonically cleaned for 10 minutes and then placed in a drying oven to dry, so that the FeCoCr and Ni 2 The surface of Al exhibits metallic luster. According to the prepared Al 0.5 The atomic molar ratio of CoCrFeNi high-entropy alloy is determined by the FeCoCr and Ni 2 The mass ratio of Al is 2.3105:1. Weigh FeCoCr and Ni 2 Al. In the present embodiment, the FeCoCr that weighs is 12kg, Ni 2 Al is...

Embodiment 2

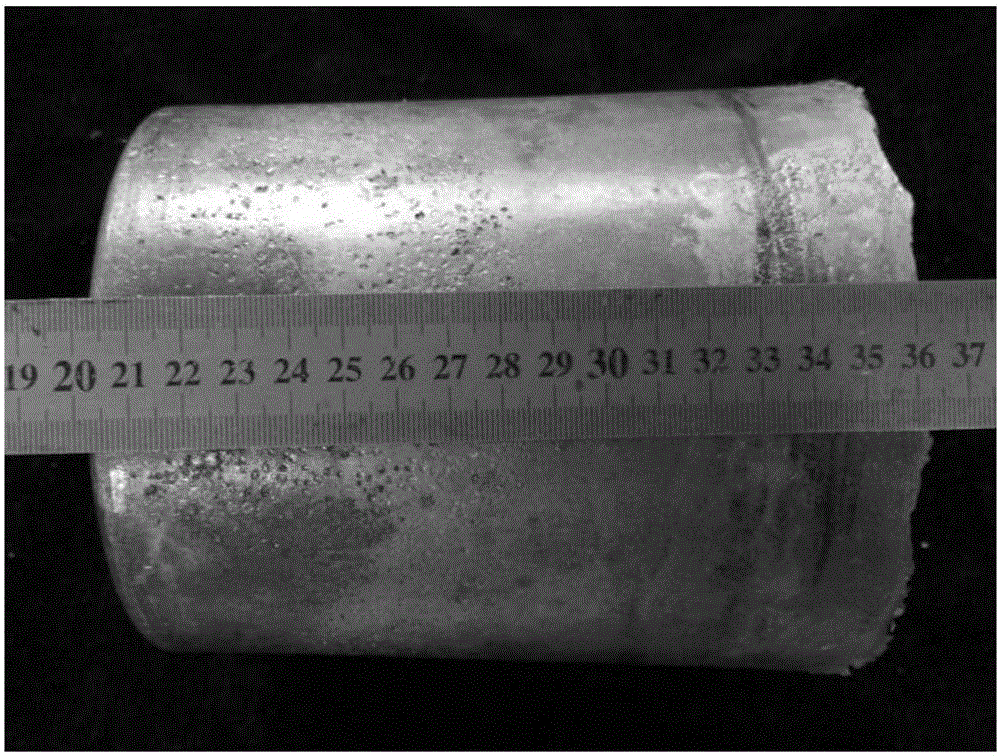

[0042] This embodiment is a method for preparing bulk Al 0.5 The method of CoCrFeNi high-entropy alloy, concrete implementation steps are as follows:

[0043] Step 1, surface treatment: for FeCoCr and Ni 2 Al surface grinding treatment. Specifically, bulk FeCoCr with a purity of 99.9wt.% and bulk Ni with a purity of 99.9wt.% 2 Al surface is polished clean. The polished FeCoCr and Ni 2 Al is placed in the acetone solution and ultrasonically cleaned for 20min and then placed in a drying oven to dry, so that the FeCoCr and Ni 2 The surface of Al exhibits metallic luster. According to the prepared Al 0.5 The atomic molar ratio of CoCrFeNi high-entropy alloy is determined by the FeCoCr and Ni 2 The mass ratio of Al is 2.3105:1. Weigh FeCoCr and Ni 2 Al. In the present embodiment, the FeCoCr that weighs is 15kg, Ni 2 Al is 6.492kg.

[0044] Step 2, furnace body preheating: add any FeCoCr or Ni into the crucible of the vacuum induction melting furnace 2 Al as a preheater...

Embodiment 3

[0053] This embodiment is a method for preparing bulk Al 0.5 The method of CoCrFeNi high-entropy alloy, concrete implementation steps are as follows:

[0054] Step 1, surface treatment: for FeCoCr and Ni 2 Al surface grinding treatment. Specifically, bulk FeCoCr with a purity of 99.9wt.% and bulk Ni with a purity of 99.9wt.% 2 Al surface is polished clean. The polished FeCoCr and Ni 2 Al is placed in the acetone solution and ultrasonically cleaned for 15 minutes and then placed in a drying oven to dry, so that the FeCoCr and Ni 2 The surface of Al exhibits metallic luster. According to the prepared Al 0.5 The atomic molar ratio of CoCrFeNi high-entropy alloy is determined by the FeCoCr and Ni 2 The mass ratio of Al is 2.3105:1. Weigh FeCoCr and Ni 2 Al. In the present embodiment, the FeCoCr that weighs is 12kg, Ni 2 Al is 5.194kg.

[0055] Step 2, furnace body preheating: add any FeCoCr or Ni into the crucible of the vacuum induction melting furnace 2 Al as a preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com