Six-element intermediate alloy for preparation of high-strength titanium alloy and preparation method thereof

A technology for master alloys and titanium alloys, applied in the field of alloy additives, which can solve the problems of difficulty in quality defects, difficulty in controlling smelting current, and inability to meet the requirements of composition ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the six-element master alloy is as follows:

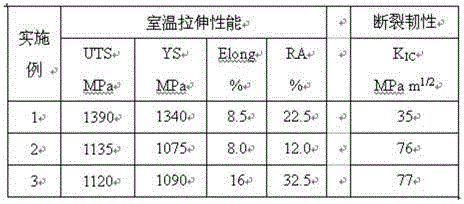

[0026] The ratio of raw materials for the production of products ranges from Al: 100 to 230 parts, MoO 3 : 125~145 copies, V 2 o 5 : 125~175 parts, Cr: 0~65 parts, Fe: 0~35 parts, CaF 2 : 15-45 parts, TiO 2 : 15-165 parts.

[0027] During production, firstly mix the raw materials uniformly according to the above ratio, put them into the reaction container, then start the ignition device to ignite in the reaction container, and carry out the aluminothermic chemical reaction smelting. The thermite smelting is carried out under the protection of helium, and the ingots obtained from the smelting are finished, broken, and selected to make finished products with a particle size of 0.05-6mm, and then sampled for inspection and packaged for storage.

[0028] When users or standards have high requirements on the uniformity of product composition and require vacuum induction melting, after the above-ment...

Embodiment 1

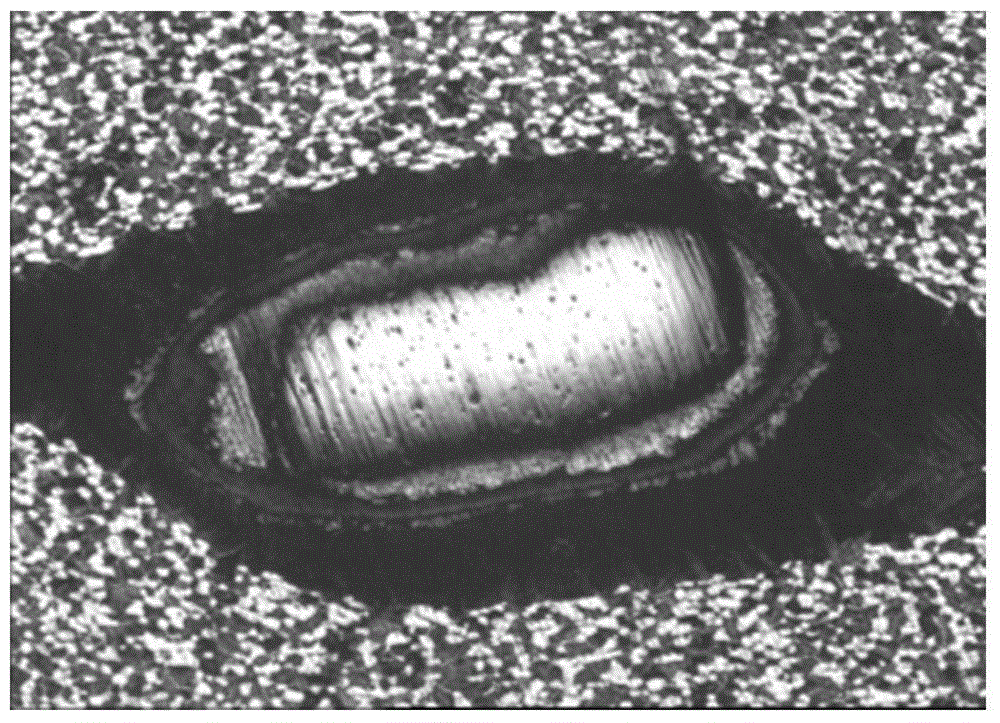

[0037] Al, MoO 3 , V 2 o 5 , Cr, Fe, CaF 2 、TiO 2 As raw material, according to the ratio of 150: 139: 165: 62: 6.3: 30: 153 parts, mix evenly, obtain alloy ingots through aluminothermic reaction, and make 0.05 ~ 6mm particle size through finishing, crushing, selection and other processes finished product. The measured composition content of the finished product is: Ti: 21.05%, Al: 23.16%, Mo: 21.89%, V: 21.89%, Cr: 10.53%, Fe: 1.47%, and the rest are impurities. The master alloy and sponge titanium, TiO 2 After the raw materials are mixed according to the mixing point required by the product standard, the titanium alloy electrode for vacuum self-consumption smelting is made through the steps of raw material stirring, mold extrusion and electrode block welding, and the composition is Ti- 5.2Al-5.2Mo-5.2V-2.5Cr-0.35Fe-0.16O multi-element high-strength high-toughness titanium alloy with high content, its microstructure after forging and heat treatment is as follows: imag...

Embodiment 2

[0039] Al, MoO 3 , V 2 o 5 , Cr, Fe, CaF 2 、TiO 2 As raw material, according to the ratio of 120:131:159:41:6.2:35:102 parts, mix evenly, obtain alloy ingots through aluminothermic reaction, and make 0.05 ~ 6mm particle size through finishing, crushing, selection and other processes finished product. The measured composition content of the finished product is: Ti: 14.19%, Al: 26.49%, Mo: 23.18%, V: 23.65%, Cr: 10.88%, Fe: 1.61%, and the rest are impurities. The master alloy and sponge titanium, sponge zirconium, TiO 2 After the raw materials are mixed according to the mixing point required by the product standard, the titanium alloy electrode for vacuum self-consumption smelting is made through the steps of raw material stirring, mold extrusion and electrode block welding, and the composition is Ti- 5.3Al-4.9Mo-5.0V-2.3Cr-1.0Zr-0.34Fe-0.11O high-strength and high-toughness titanium alloy with high multi-element content, its microstructure after forging and heat treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com