Ti-rich high-entropy alloy with high specific strength, high plasticity and high toughness and preparation of Ti-rich high-entropy alloy

A technology of high-entropy alloy and high specific strength, which is applied in the field of Ti-rich high-entropy alloy and its preparation, which can solve the problems of difficult combination, achieve good corrosion resistance, ensure the uniformity of composition and structure, and the effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

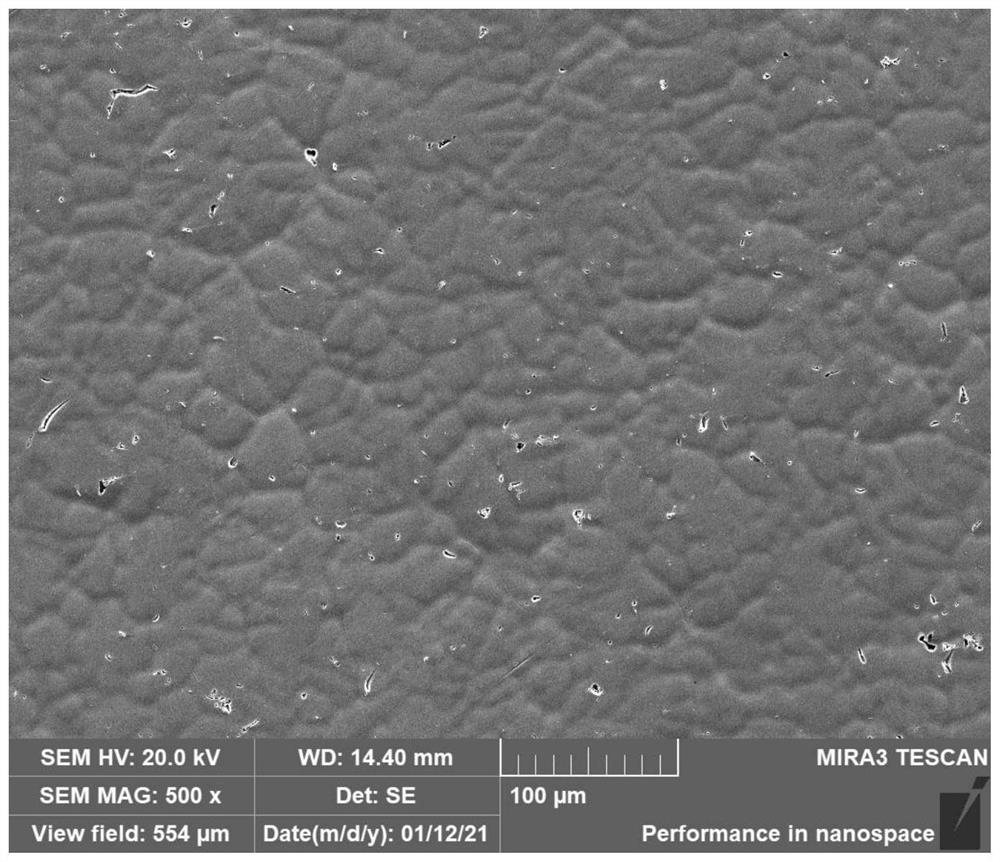

[0042] A Ti with high specific strength, high plasticity and high toughness 46 Zr 23 Nb 16 V 15 The preparation of high entropy alloys, the specific steps are as follows:

[0043] Step (1): According to the alloy composition, convert the atomic percentage into mass percentage Ti:Zr:Nb:V=34:32:23:11 and weigh the ingredients; the raw materials used are all industrial-grade pure particles, and the particle size range is 1~3mm, clean and dry the weighed raw material particles, put them into a three-dimensional mixer, and put a certain quality of steel balls at the same time (the mass ratio of raw materials to steel balls is 1:1~3, and the diameter of steel balls is 15 ~30mm), so as to obtain a homogeneous mixture of raw materials.

[0044] Step (2): The obtained raw material mixture is compacted into a block by a press, and a raw material block with a relatively uniform composition is preliminarily obtained, and the maximum pressure of the raw material block is 500 MPa.

[0...

Embodiment 2

[0048] The difference from Example 1 is that the alloy composition in this example is Ti 44 Zr 22 Nb 15 V 15 Al 4 .

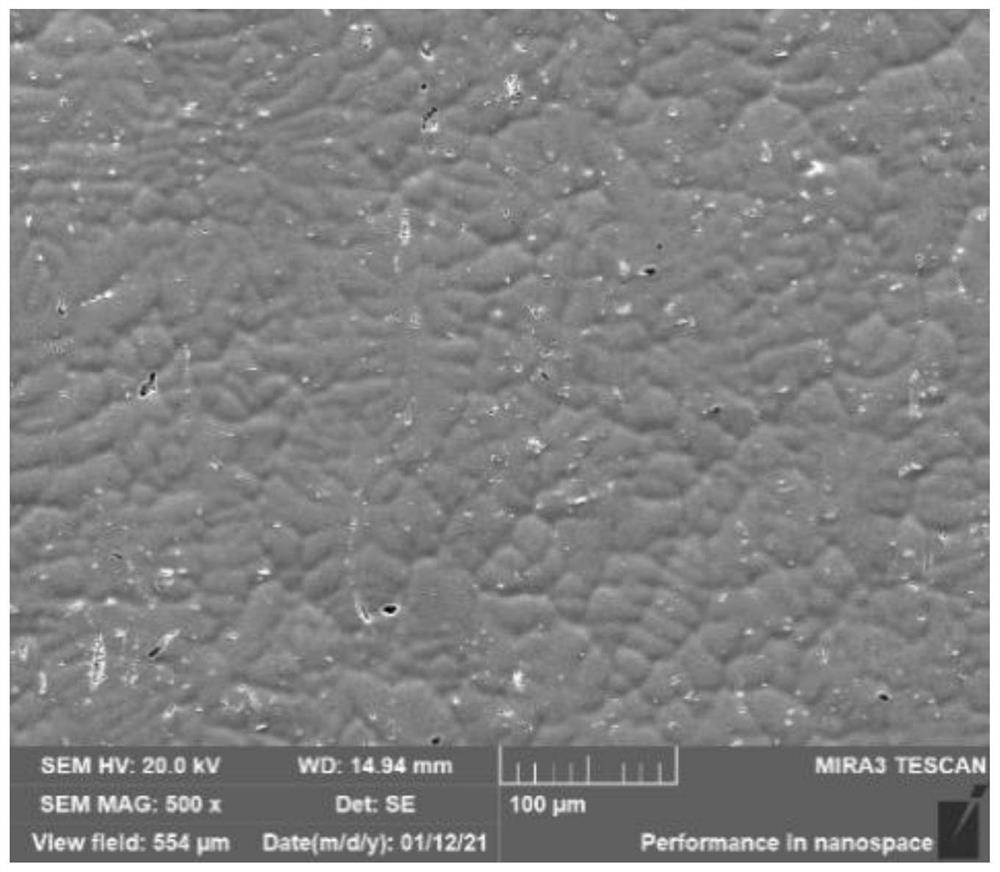

[0049] see figure 2 It can be seen that the as-cast Ti of the embodiment of the present invention 44 Zr 22 Nb 15 V 15 Al 4 The high-entropy alloy structure is a typical cast dendrite structure, but the dendrite and interdendritic elements are not obvious, and it is more inclined to the near equiaxed crystal structure. see Figure 5 The XRD collection of illustrative plates can find out that the as-cast state Ti of the embodiment of the present invention 44 Zr 22 Nb 15 V 15 Al 4 High-entropy alloys have a single BCC crystal structure at room temperature. See Table 1 and Figure 6 It can be seen from the room temperature tensile test results that the alloy density is 5.765g / cm 3 , the yield strength is 897MPa, and the elongation at break exceeds 20%.

Embodiment 3

[0051] The difference from Example 1 is that the alloy composition in this example is Ti 44 Zr 22 Nb 14 V 13 Al 7 .

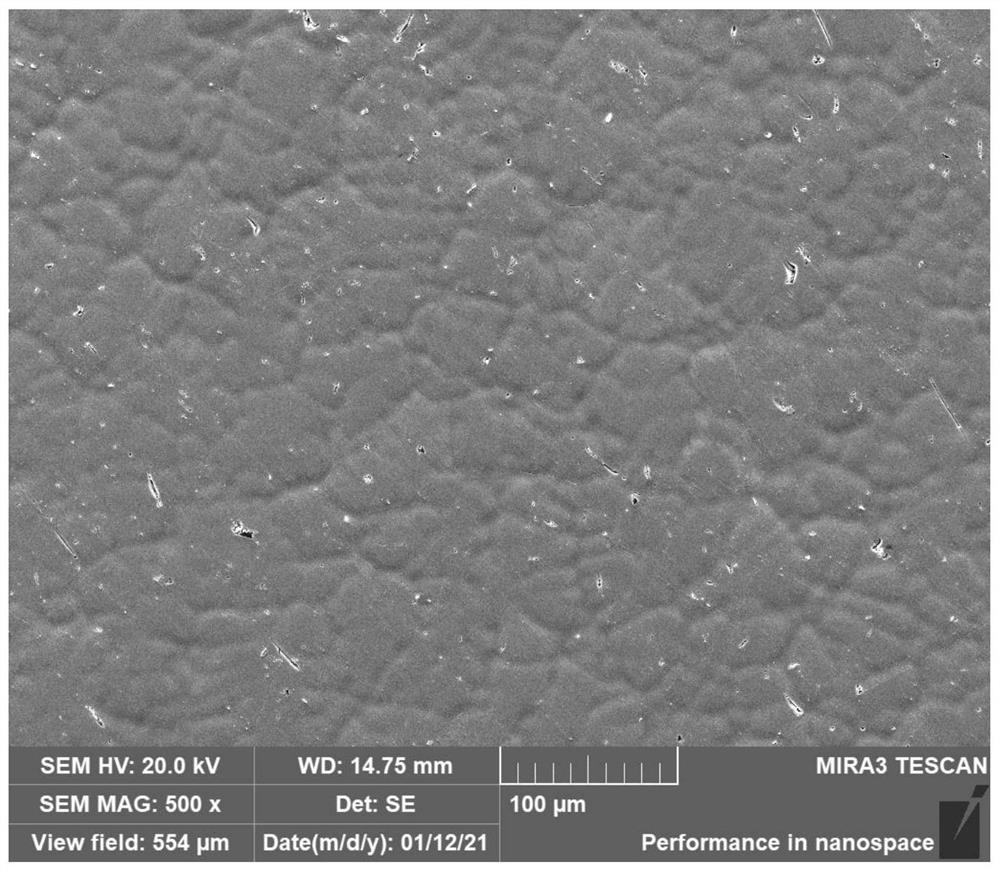

[0052] see image 3 It can be seen that the as-cast Ti of the embodiment of the present invention 44 Zr 22 Nb 14 V 13 Al 7 The high-entropy alloy structure is a typical cast dendrite structure, but the dendrite and interdendritic elements are not obvious, and it is more inclined to the near equiaxed crystal structure. see Figure 5 The XRD collection of illustrative plates can find out that the as-cast state Ti of the embodiment of the present invention 44 Zr 22 Nb 14 V 13 Al 7 High-entropy alloys have a single BCC crystal structure at room temperature. See Table 1 and Figure 6 It can be seen from the room temperature tensile test results that the alloy density is 5.674g / cm 3 , the yield strength of the alloy is 1041MPa, and the elongation at break is also maintained at 10% to 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com