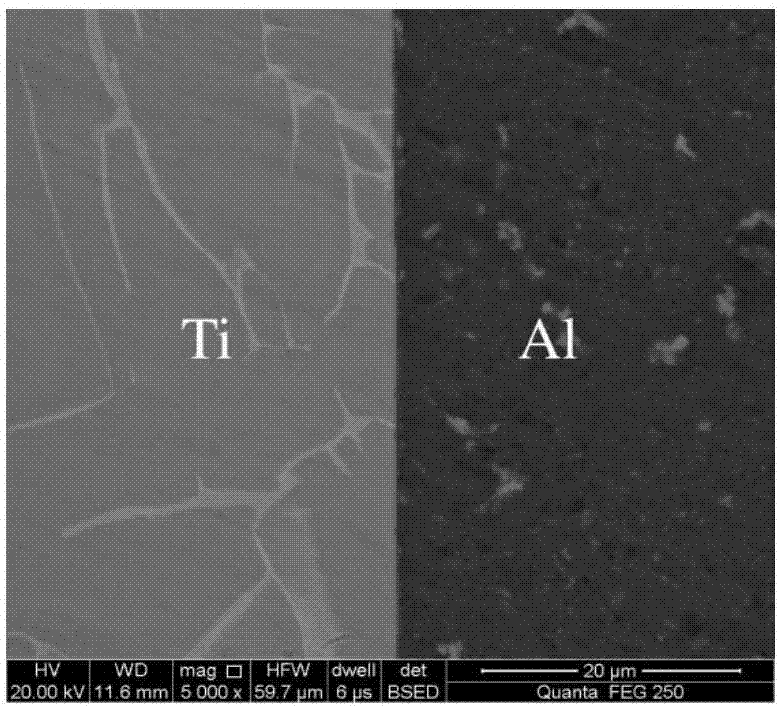

Titanium/aluminum gradient material and preparation method thereof

A gradient material and material technology, applied in the field of high-performance materials and their preparation, can solve problems such as difficult to obtain titanium/aluminum gradient structure, difficult to control interface reaction, large residual stress, etc., to ensure composition uniformity and tissue stability, Avoid the effect of excessive grain growth and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The powder metallurgy preparation method of the high-performance titanium / aluminum gradient material described in this embodiment is carried out according to the following steps:

[0049] Step 1: Powder pretreatment; TC4 powder with a particle size of 58 μm and 2A12 powder with a particle size of 58 μm were dried in an oven at 80° C. for 4 hours.

[0050] Step 2: Molding; a hard alloy mold with a diameter of 40 mm is used, and a layer of stearic acid is pre-coated on the inner wall of the mold to facilitate demoulding. The TC4 powder and the 2A12 powder were respectively placed in the mold for compression molding, and the pressing pressure was 20 MPa, and the holding time was 20 s to obtain titanium matrix and aluminum matrix compacts respectively, and the thickness of the prepared matrix was 10 mm.

[0051] Step 3: Sintering and densification of the titanium substrate; firstly, the temperature is raised from room temperature to 600°C at a heating rate of 10°C / min and k...

Embodiment 2

[0057] The powder metallurgy preparation method of the high-performance titanium / aluminum gradient material described in this embodiment is carried out according to the following steps:

[0058] Step 1: Powder pretreatment; TC4 powder with a particle size of 45 μm and 2A12 powder with a particle size of 58 μm were dried in an oven at 80° C. for 4 hours.

[0059] Step 2: Molding; a hard alloy mold with a diameter of 40 mm is used, and a layer of stearic acid is pre-coated on the inner wall of the mold to facilitate demoulding. The TC4 powder and the 2A12 powder were respectively placed in the mold for compression molding, and the pressing pressure was 10 MPa, and the holding time was 30 s to obtain titanium matrix and aluminum matrix compacts respectively, and the thickness of the prepared matrix was 15 mm.

[0060] Step 3: Sintering and densification of the titanium substrate; firstly, the temperature was raised from room temperature to 600°C at a heating rate of 10°C / min and ...

Embodiment 3

[0066] The powder metallurgy preparation method of the high-performance titanium / aluminum gradient material described in this embodiment is carried out according to the following steps:

[0067] Step 1: Powder pretreatment; TC4 powder with a particle size of 48 μm and 2A12 powder with a particle size of 53 μm were dried in an oven at 80° C. for 6 hours.

[0068] Step 2: Molding; a cemented carbide mold with a diameter of 20 mm is used, and a layer of stearic acid is pre-coated on the inner wall of the mold to facilitate demoulding. The TC4 powder and the 2A12 powder were respectively placed in the mold for compression molding, and the pressing pressure was 10 MPa, and the holding time was 30 s to obtain titanium matrix and aluminum matrix compacts respectively, and the thickness of the prepared matrix was 15 mm.

[0069] Step 3: Sintering and densification of the titanium substrate; first, the temperature was raised from room temperature to 600°C at a heating rate of 10°C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com