A kind of mag horizontal welding welding method and process

A welding method and welding process technology, applied in the field of MAG horizontal welding welding method and process, can solve the problems of welding operation troubles, "mountain"-shaped weld bead, small welding parameters, etc., to avoid large discrete type and simplify process control. The effect of ensuring the uniformity of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

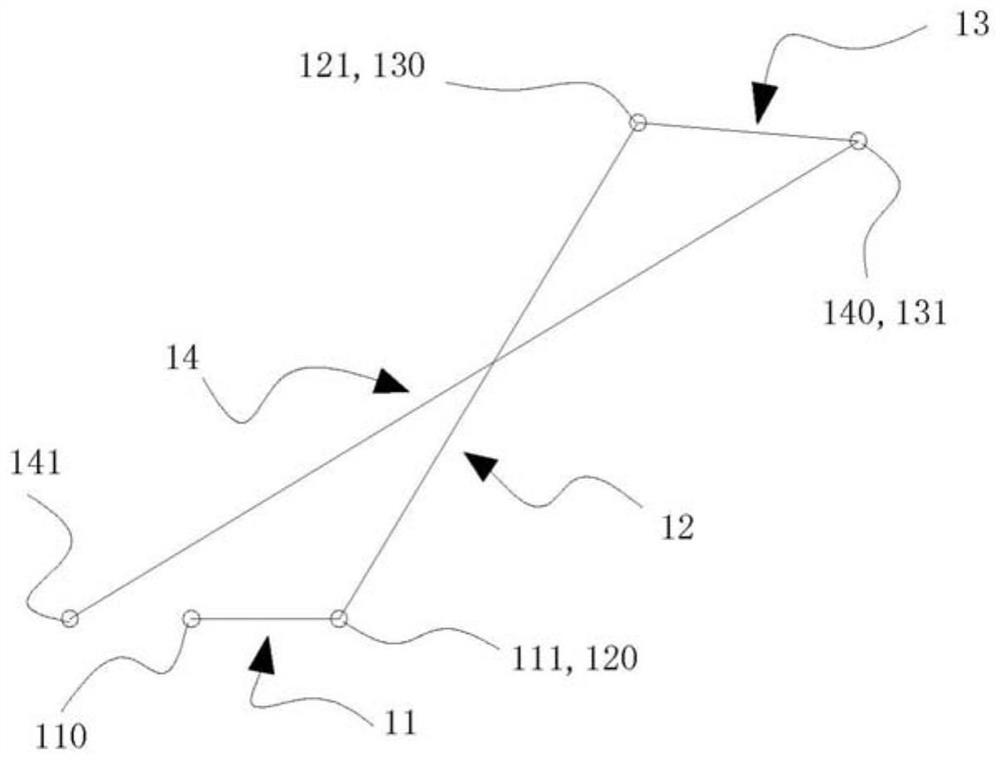

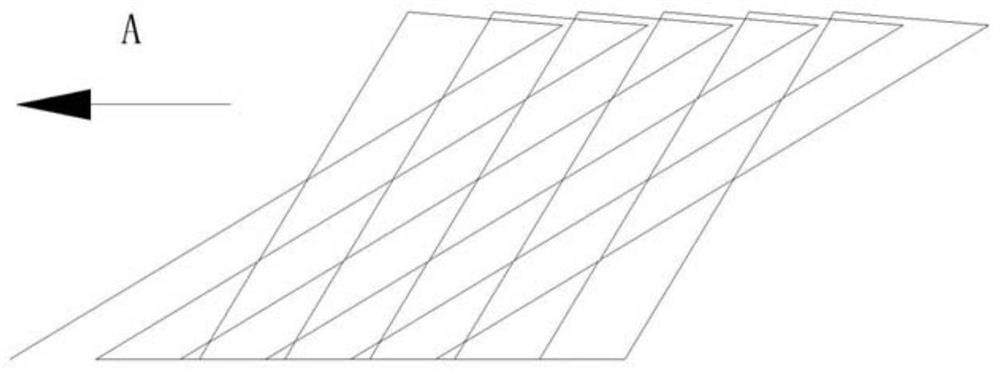

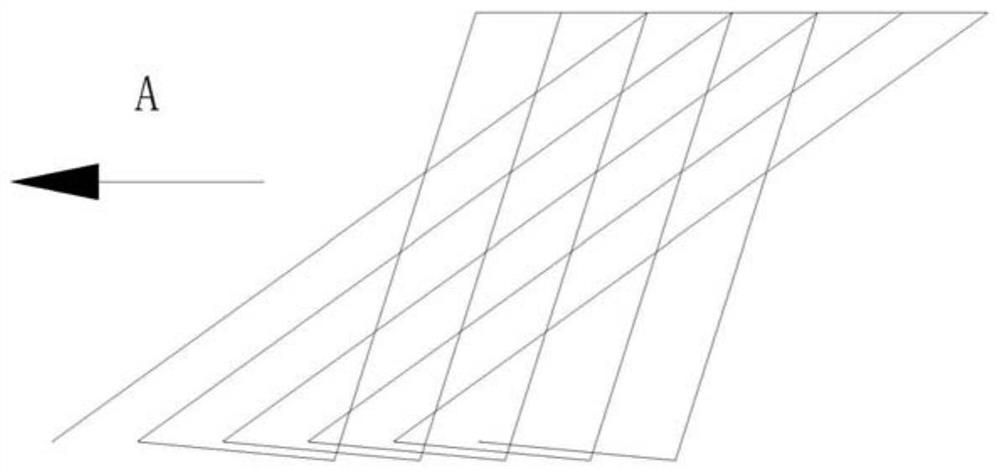

[0055] Such as Figure 1 to Figure 3 As shown, in the MAG horizontal welding welding method in this embodiment, the formed weld seam includes a plurality of connected track units, and a plurality of track units are arranged in sequence along the welding operation direction A, and each track unit includes a plurality of head and tail phases Followed welding trajectory. By dividing the welding seam into multiple trajectory units, the control of the process parameters of the trajectory units can be realized to control the welding process, and the industrial control work of the welding operation can be simplified.

[0056] The MAG horizontal welding method introduced in this embodiment includes the first piece and the second piece to be welded, the first piece can be located above the second piece, obliquely above or both at the same level. Both corresponding positions are welding joints, and the method comprises the following steps:

[0057] S1. Determine the relative position ...

Embodiment 2

[0065] The difference between the MAG horizontal welding method in this embodiment and the above embodiment is that each track unit includes four welding tracks. The setting of four welding trajectories can meet the welding requirements of larger weld seam size, larger groove size, and larger welded joint size. The area swept by the four trajectories can basically be approximated as a quadrilateral. Carrying out this "quadrilateral" division of the weld seam ensures that the sweeping conditions of the weld seam are the same in the process of gun transportation, thereby ensuring that the middle part of the weld seam Same as the welding on both sides of the weld, it can also increase the sweeping area of the welding torch on the base metal, thereby increasing the base metal penetration.

[0066] Furthermore, in the MAG horizontal welding method in this embodiment, the included angle between each of the welding tracks and the welding operation direction is an obtuse angle. The...

Embodiment 3

[0069] Such as figure 2 As shown, the difference between the MAG horizontal welding welding method in this embodiment and the above-mentioned embodiment is that: the track unit includes the first track 11, the second track 12, the third track 13 and the fourth track 14 which are sequentially connected end to end. . The welding operation also forms each welding track separately in this order. In each trajectory unit, the trajectory end point 141 of its fourth trajectory is located between the trajectory start point 110 of its first trajectory and the end point of the welding operation (the end point of the weld seam). The trajectory start point of the first trajectory of each trajectory unit (except the first welding unit) coincides / connects with the trajectory end point of the fourth trajectory of the previous welding unit. Repeatedly, a plurality of trajectory units are connected at the end to form a welding seam. Moreover, the design of the technical solution in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com